11

© Baxi Heating UK Ltd 2012

8.0 Combustion Re-calibration

Combustion Re-calibration

Each boiler is calibrated during manufacture and set during F.F.T. (Final Function Testing). This sets the Fan and E.G.V.

(Electronic Gas Valve) to the rest of the system. Combustion at F.F.T. is set at 9.0% +/- 0.2% on N.G.

The system must be re-calibrated by the engineer to the procedure below if any of the following are changed:-

• Gas Valve

• R.D.S. (Removable Data Stick)

• Burner

• Fan

IT IS ESSENTIAL THAT THE

CALIBRATION PROCESS IS

STARTED WHEN THERE IS NO

DEMAND !

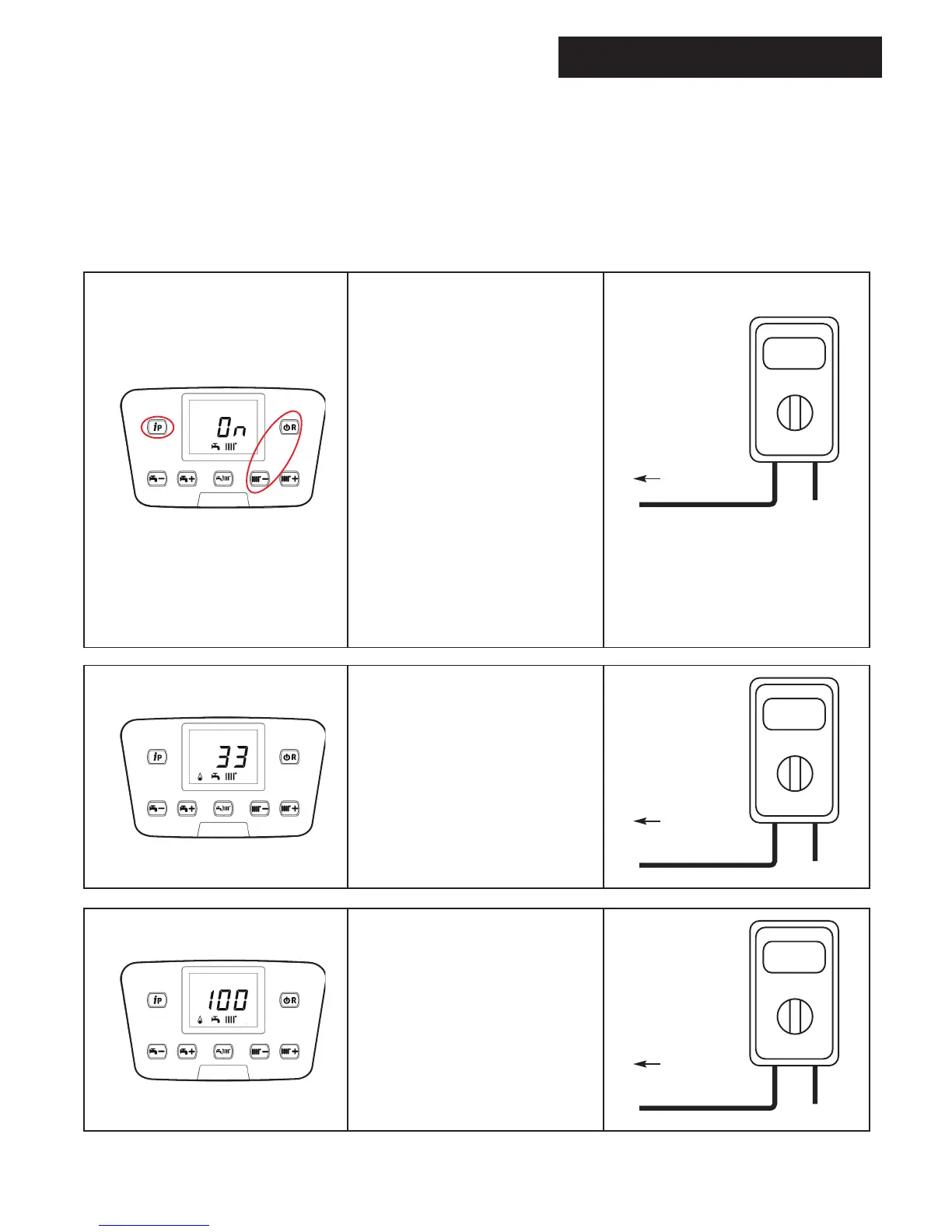

Press the ‘CH -ve’ and reset ‘R’

buttons together for 6 seconds.

‘On’ will be displayed and within 2

seconds of this showing press the ‘ip’

button.

If ‘303’ is displayed, the time window

to press the ‘ip’ button has been

missed. Power down at the fused spur

and start again.

DO NOT TURN ON THE

ANALYSER PUMP WHILST THE

BOILER IS CALIBRATING AS THE

INTERNAL CELL MAY BECOME

SATURATED !

Remove the boiler front door and

connect the manometer to the Inlet

Test point on the Gas Valve.

After the ‘ip’ button is pressed the

Ignition Fan Speed (as % of maximum)

will be displayed. Each model is

different (e.g. 33GA is ‘41’).

The boiler software will now search

for the appropriate ignition curve to

light with, usually curve 3 or 4.

To G.V. Inlet

Test Point

To G.V. Inlet

Test Point

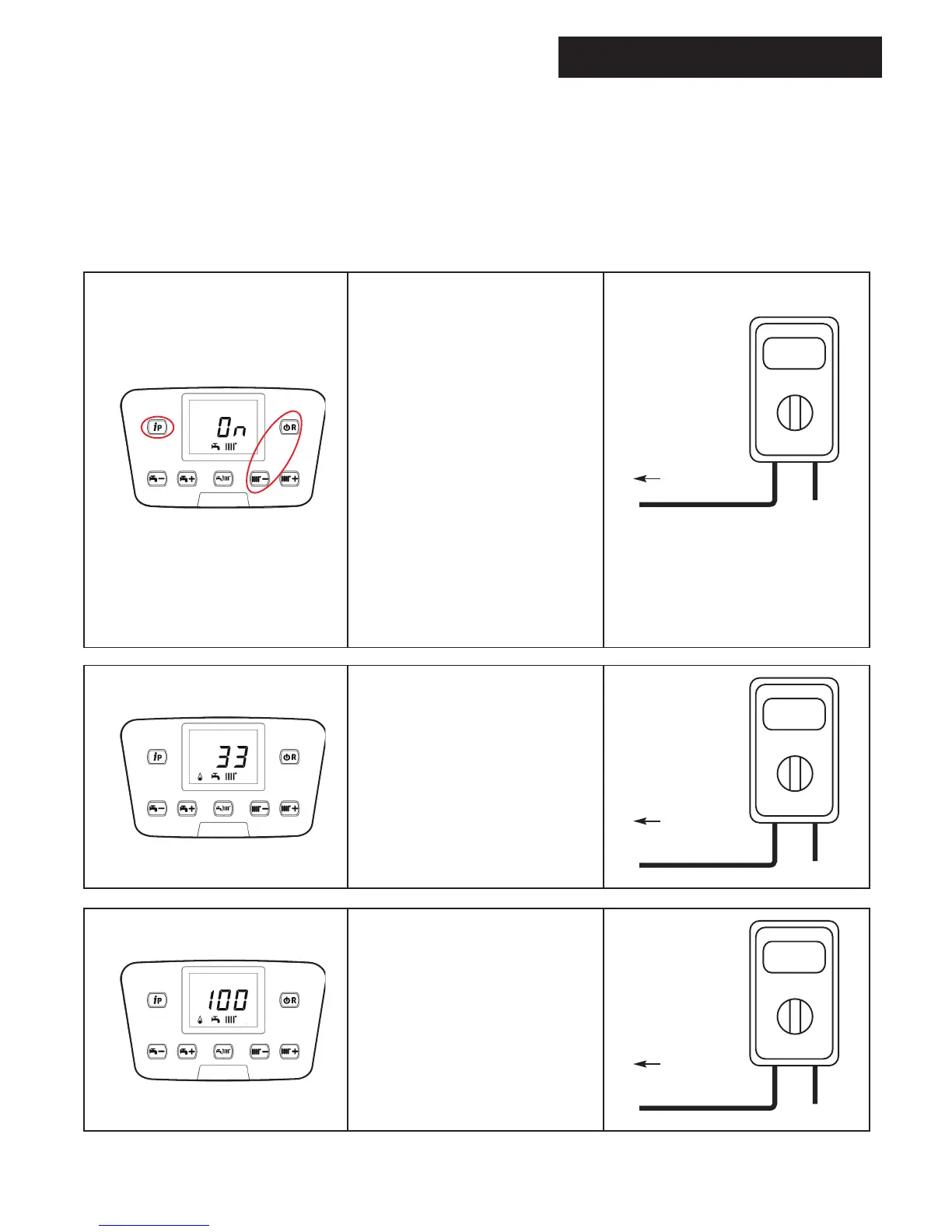

After several seconds ‘100’ will be

displayed, indicating that the fan is a

maximum speed. It may be necessary

to put a D.H.W. demand on the

system if the temperature exceeds

85 °. Check the gas inlet pressure has

not dropped below 16mb.

The boiler will remain at ‘100’ until

stabilization is achieved - up to 3

minutes.

To G.V. Inlet

Test Point

>16mb

Combined Analyser/Manometer

Loading...

Loading...