NOTE: Refer to oven installation checklist and

complete during initial start-up.

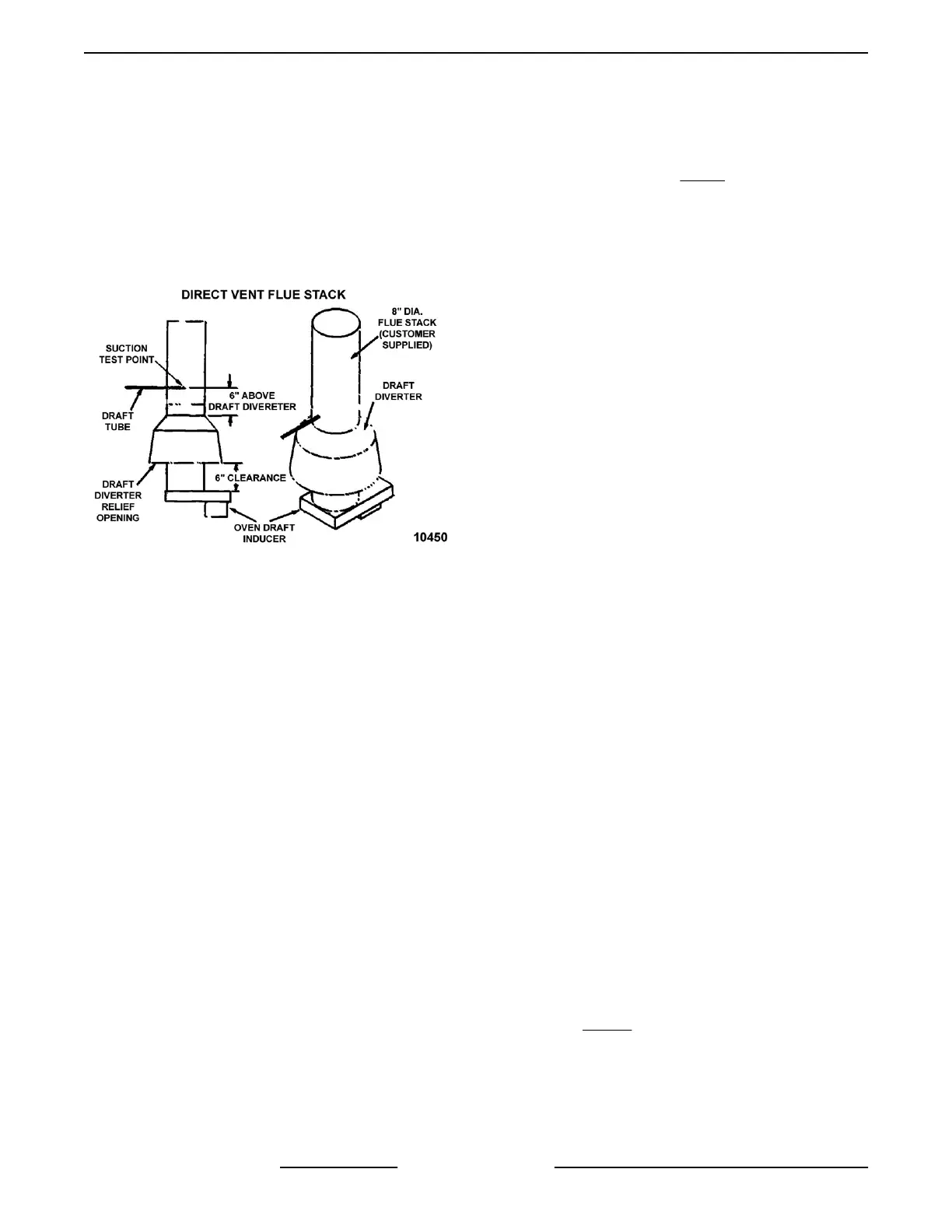

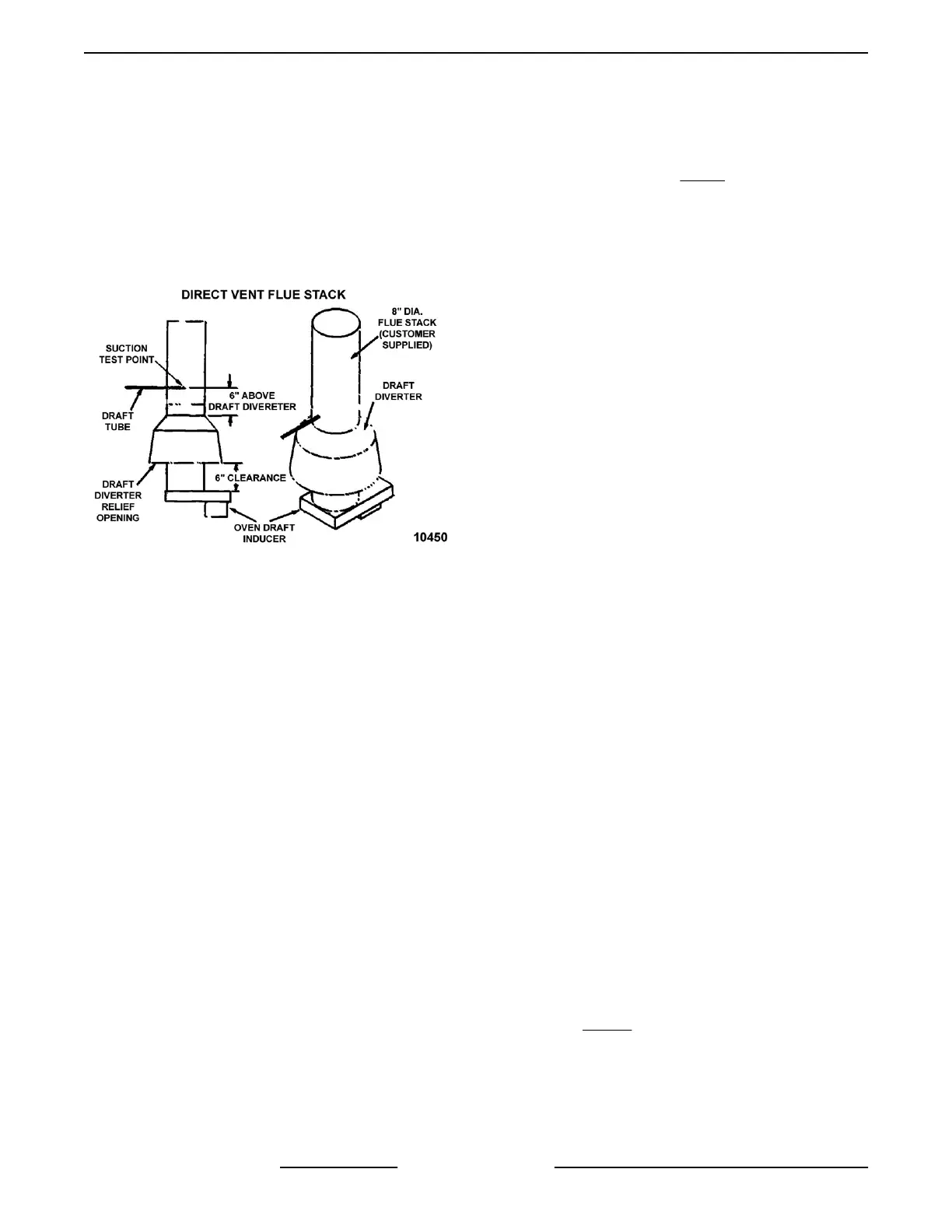

1. Verify flue draft (direct vent with gas oven only).

A. Insert a draft tube into the flue stack 6"

above the top of the draft diverter. If

required, drill a hole in flue stack to insert

draft tube.

B. Connect a incline manometer or equivalent

to the draft tube.

Fig. 6

C. With the oven turned off and doors closed,

check the manometer reading. Reading

should be a vacuum of 0.03" to 0.11" W.C.

1) If vacuum requirements are met,

proceed to step D.

2) If vacuum requirements are not met,

the customer supplied flue stack must

be modified to meet the above stated

requirements.

3) After flue stack change has been done,

repeat the procedure.

D. Operate the oven for a minimum of 5

minutes.

1) While burner is lit, check for a back

draft at the draft diverter relief opening

(i.e. smoke emitted from a smoldering

source).

2) If no back draft indicated (smoke going

up draft diverter relief opening) test is

complete.

3) If back draft indicated (smoke not going

up draft diverter relief opening) the

oven must not be operated, until proper

adjustments have been made (correct

flue stack to have adequate up draft

through the draft diverter relief

opening).

E. Verify oven rack rotates and baking

compartment circulation fan is turning. If not,

door switches will need to be adjusted, as

outlined under DOOR SWITCH

ADJUSTMENT Step 4.

NOTE: Baking compartment circulation fan will run

continuously with time entered in the bake timer and

cycle on/off with heating circuit if no time is entered in

the bake timer.

2. Ignition Sequence Check (Gas Ovens Only).

NOTE: Ignition module makes one attempt to light

burner before locking out.

NOTE: Remove power from ignition control module

by turning main circuit breaker to oven off or by

opening the loading doors for a minimum of 5

seconds.

A. Turn gas valve off to test ignition sequence

check.

B. Set oven to call for heat by pressing bake

temperature display UP ARROW key, until

HEAT ON LED illuminates.

C. Draft inducer energized for 15 seconds pre-

purge cycle.

D. Hot surface igniter glows indicating that it is

energized.

E. 2 seconds after igniter was energized, gas

valve solenoid is energized.

F. After igniter has been energized for 4

seconds, flame sensor will not have

recognized a flame.

1) Power is removed from igniter and gas

valve.

G. After initial try for ignition and the burner has

not lit, there will be an additional 15 second

purge time.

H. LED on ignition control will flash in a 3 flash

sequence indicating a flame recognition

failure and that the control is in lock-out

mode.

I. This indicates the safety lock-out circuit is

functioning properly.

NOTE: See IGNITION SEQUENCE TIMING

DIAGRAM Fig. 19

3. Gas Pressure Adjustment (Gas Ovens Only).

A. Remove the gas valve cover to access the

gas valve pressure taps.

OV310 Series Mini Rack Oven Installation Instructions - INSTALLING OVEN

F25422 Rev. B (0917) Page 10 of 16

Loading...

Loading...