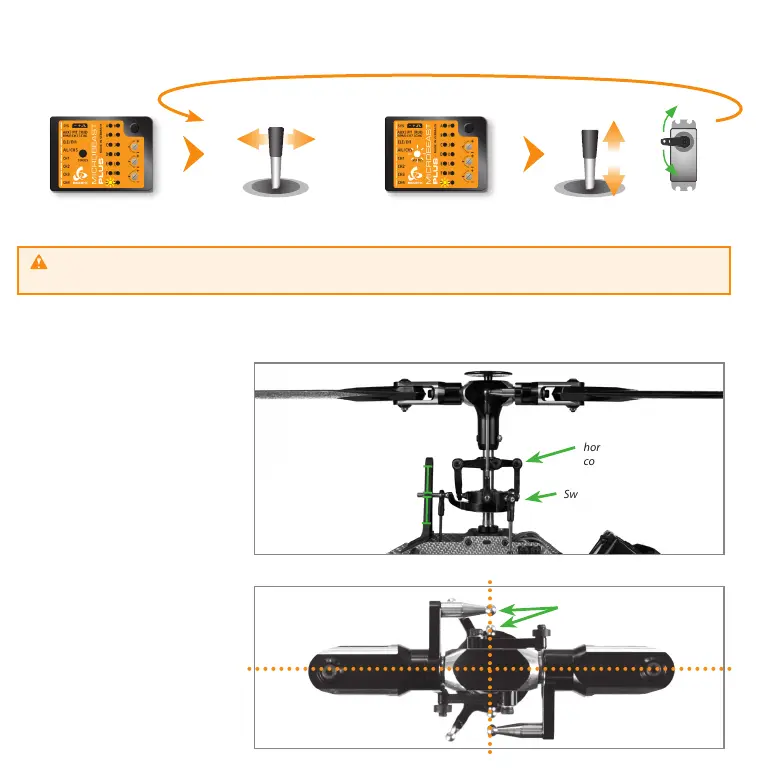

By moving the rudder stick into one direction repeatedly select one servo after another and adjust each servo‘s center position

by moving the elevator stick forwards or backwards so that the servo arm is positioned exactly 90 degrees to the linkage rod.

The servo number that is currently selected and that can be trimmed at the moment is indicated by the Status LED color.

When the servos are adjusted perfectly let one servo selected (only the electrical trim positions are important and are used in

the further steps) and adjust the linkage rods going from servos to the swashplate and from the swashplate to the blade grips.

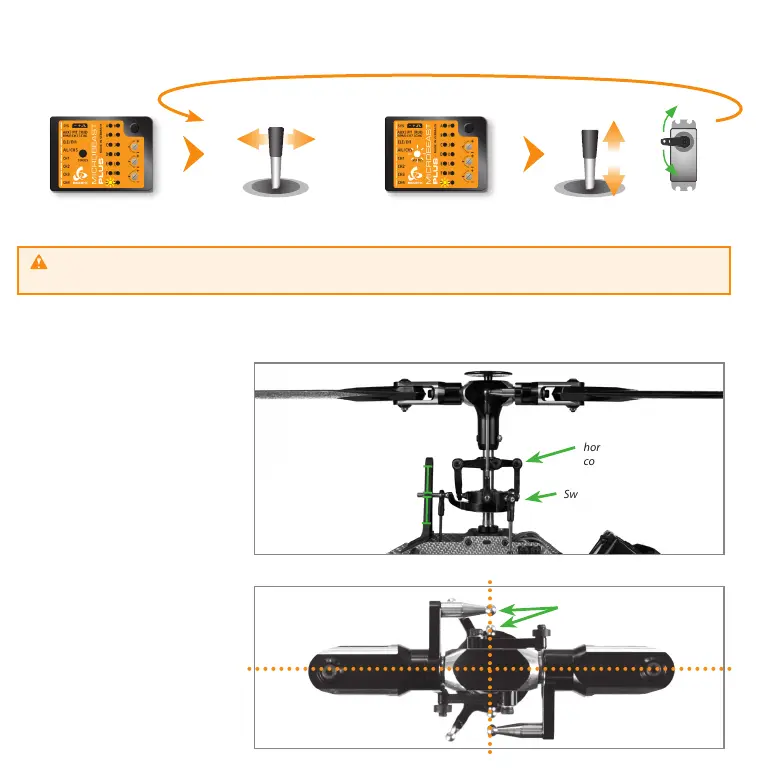

Anti-rotation guide leveled

horizontally and twisted

correctly

Swashplate leveled horizontally

0° pitch

Swashplate centered

vertically on main shaft

Status LED o

(= no servo active)

Choose one of the servos

connected at CH1 - CH3

Move rudder stick

left or right

Status LED color indicates

selected servo number

Move elevator stick to adjust servo

center position

Check all servo positions by selecting each servo once even when the servo arms are perfectly positioned when

Status LED is off.

If necessary adjust the swashplate

anti-rotation guide so that there is no

swashplate phasing (only applies to

2-blade rotorheads).

Linkage balls of swashplate outer

ring and blade grips must be on

one line

The swashplate must be leveled

and centered on the main shaft

and the bladegrips should be set

to 0° pitch. Then briey push the

button to get to menu point H.

Loading...

Loading...