6 7

GAS SPECIFICATIONS

GAS SPECIFICATIONS LEAK TEST PROCEDURE

LEAK TEST PROCEDURE

GAS TYPE

NATURAL

GAS

UNIVERSAL

LPG

PROPANE

Maximum gas

consumption

67.2 MJ/h 64.0 MJ/h 71.0 MJ/h

Injector office

diameter

1.75mm 0.90mm 0.95mm

Number of

injectors

6 6 6

Regulator

pressure

1.00 kPa 2.75 kPa 2.75 kPa

NOTES:

• This appliance MUST be installed and serviced only by a

qualified licensed person.

• This product must be installed as per the instructions

which requires the installation of venting to enable

the barbecue to operate correctly. Failure to provide

adequate ventilation for supply of air to the appliance

may result in poor burner performance or excessive

heat build-up within the mounting enclosure.

• Ventilation holes in the unit must not be obscured by the

installation.

Failure to adhere to these installation instructions may

affect your ability to make a claim under the manufacturer’s

warranty.

Natural gas installation

This barbecue is set up for Natural Gas and is labelled

accordingly. A Universal LPG and Propane conversion kit is

included if required.

Connecting the appliance to an NG gas supply

Componets supplied in a bag for NG are:

• 1 x Natural gas regulator

• Natural gas installation pipe

• 2 x sealing washers

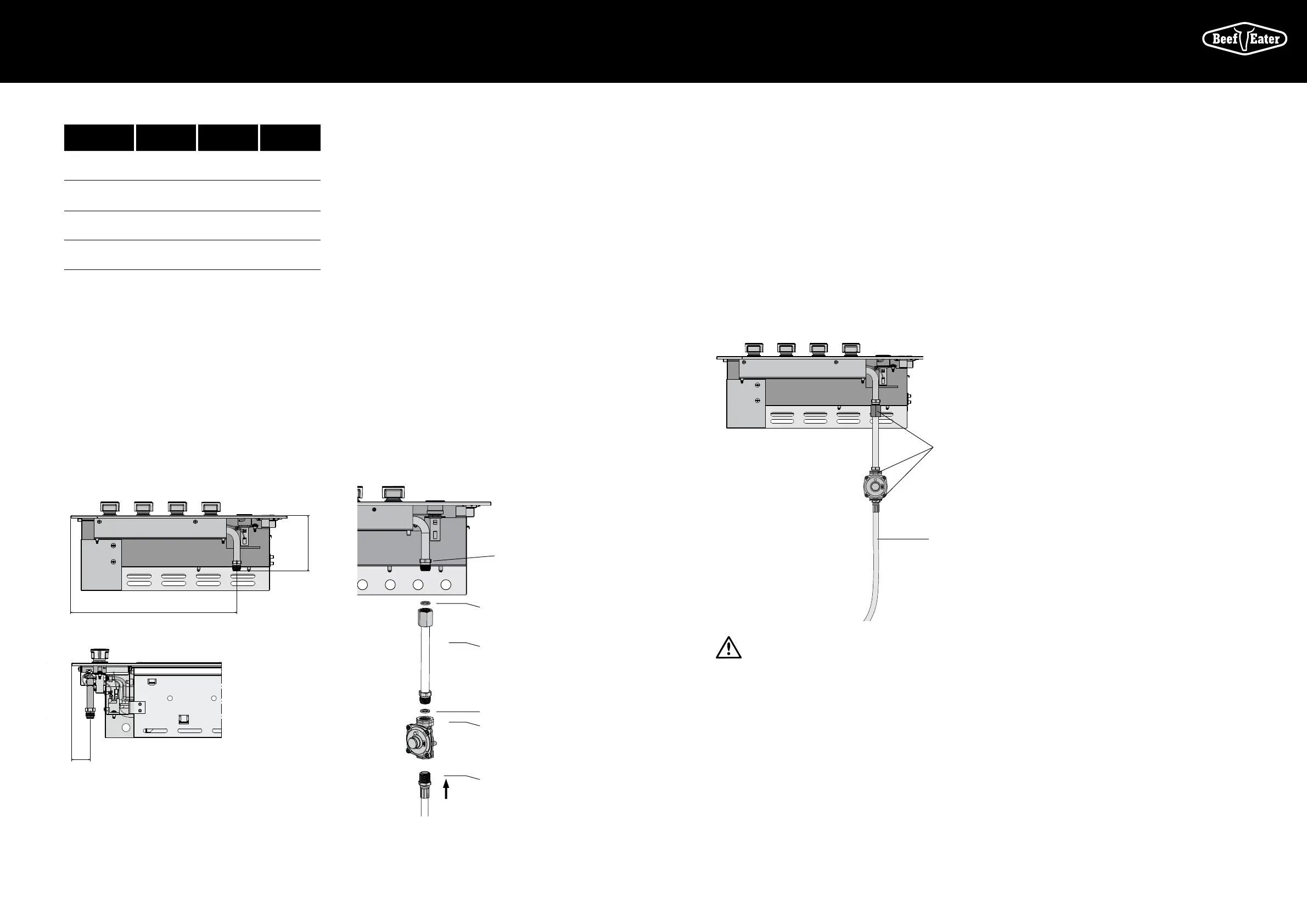

1. Fitting the Natural Gas installation

• Fit the pipe ensuring the blue sealing washer is in

place. Do not over-tighten.

2. Fitting the regulator

• Fit the regulator ensuring the blue sealing washer

is in place and the arrow indicating gas flow is

correct. Do not over-tighten.

3. Fit the hose

• Connect to consumer piping

- The NG regulator inlet has a 1/2” parallel pipe thread.

- The inlet of the NG regulator may be connected to

consumer piping using a suitable hose assembly if

required.

408mm

46mm

137mm

Preparing the unit for Natural Gas connection to mains

Natural gas connection to be made by a licenced gas fitter.

Regulator – ensure

arrow is pointing in the

right direction

Consumer piping

Sealing washer

Natural Gas

installation pipe

Barbecue gas inlet

Sealing washer

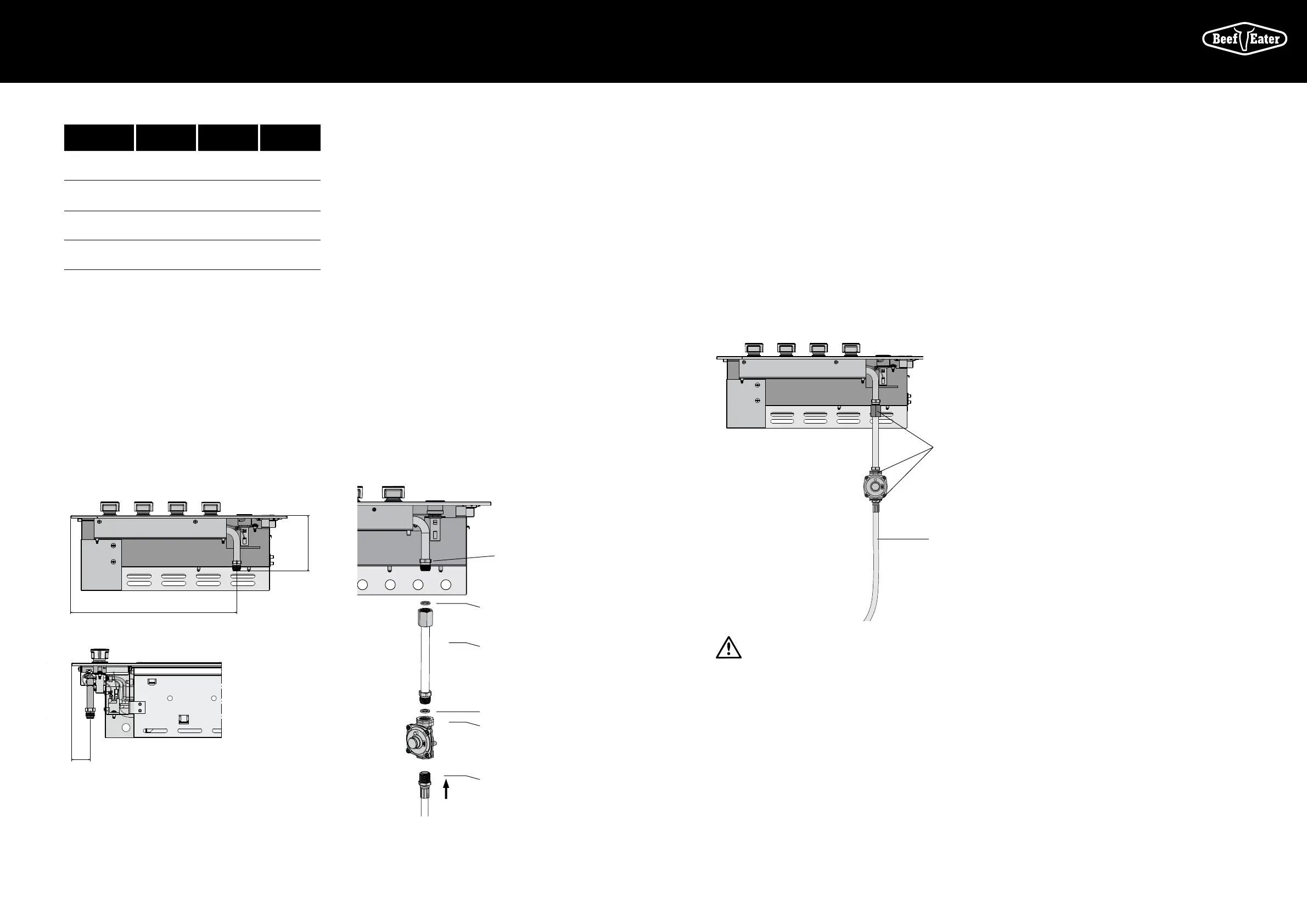

• Ensure all gas valves are in the ‘OFF’ position.

• In a small container, mix a solution of water and

detergent or soap.

• After connection of the hose, turn on the gas supply at

the gas bottle or mains as appropriate.

• Using a brush apply the solution to the gas connection

points and look for bubbles forming.

• Bubbling will indicate a leak.

• Turn off the gas supply and re-tighten the joint. Repeat

the leak test.

• If the leak persists, turn off the gas at the isolation

valves and contact a licensed gas fitter to correct.

WARNING

Failure to ensure gas tight connections and complete the gas

leak test procedure before use and after every reconnection

to a gas cylinder may result in a fire or explosion.

Leak test procedure

Leak test

points

Check hose

for signs of

abrasions, cracks

or leaks

Loading...

Loading...