74

86105 BA-en/00

English ⋅ Nautilus

®

CC plus ⋅ Nautilus

®

T

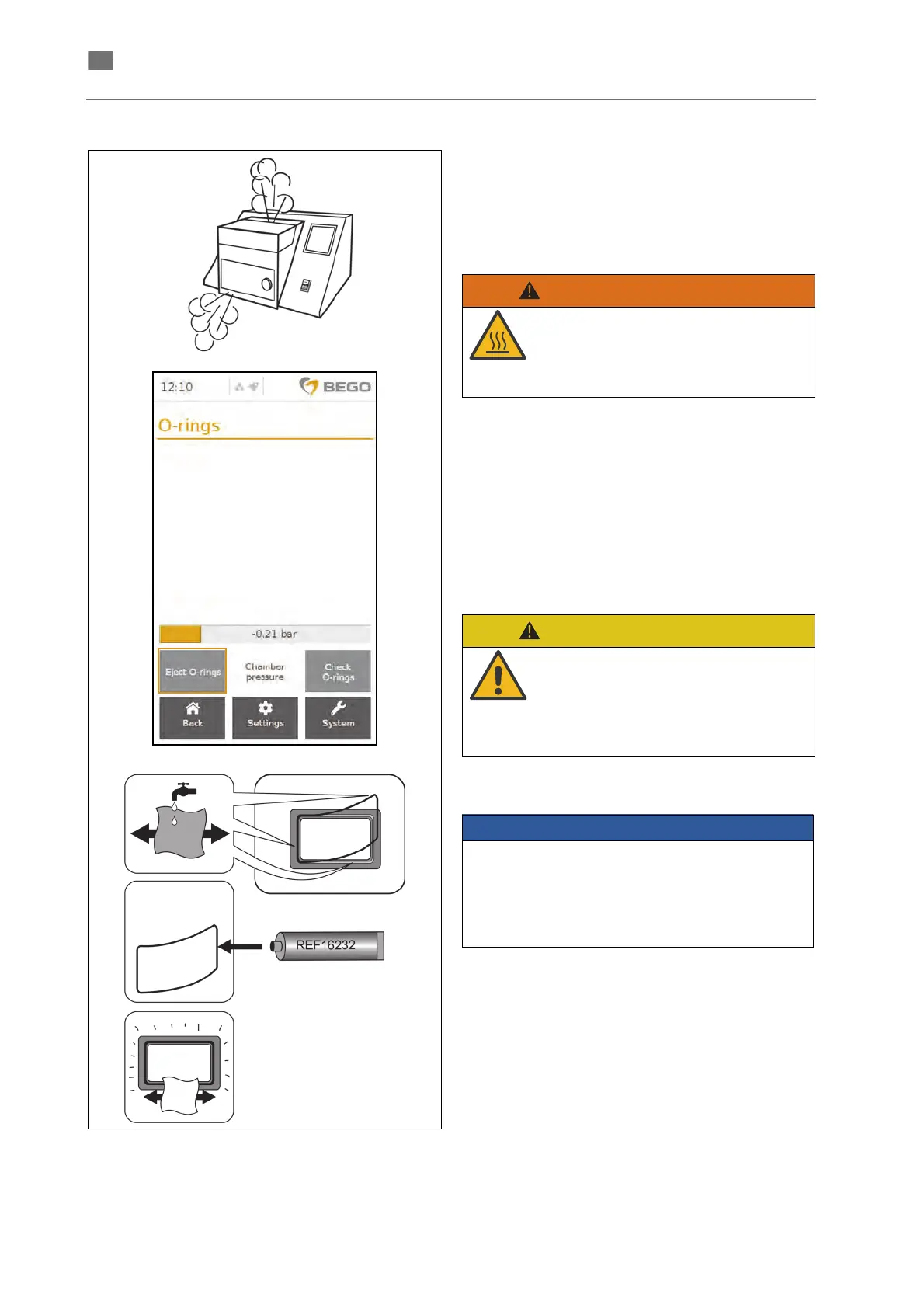

Ejecting and cleaning the seals

Dirty O-rings on the openings to the casting

chamber (e.g. residual investment material) may

lead to leaks that would create some noise.

Moreover, the vacuum and pressure values may

change, which could lead to faulty casting results.

O-rings can be ejected with compressed air.

1. Open the mould flap.

2. Go to Settings > O-rings > Eject O-rings (1).

The O-ring will be released with compressed

air.

3. Remove the O-ring.

4. Clean the O-ring, grooves and sealing sur-

faces with a cloth and isopropyl alcohol.

5. Slightly grease the O-rings with seal grease

(REF 16232).

6. Remove surplus grease with a dry cloth!

7. Insert the seal again

8. Repeat the process with the crucible flap.

9. Check the seals, see page 75.

Burn hazard from hot parts!

Carry out maintenance and cleaning

work before casting or after the device

has cooled down.

The grease is difficult to remove

from skin and clothing.

Wear the protective clothing and

gloves prescribed for use in dental

laboratories!

• Do not overstretch the seal when cleaning and

inserting!

• Do not interchange the seals, they have differ-

ent sizes! A seal with a poor fit leads to leak-

age.

Loading...

Loading...