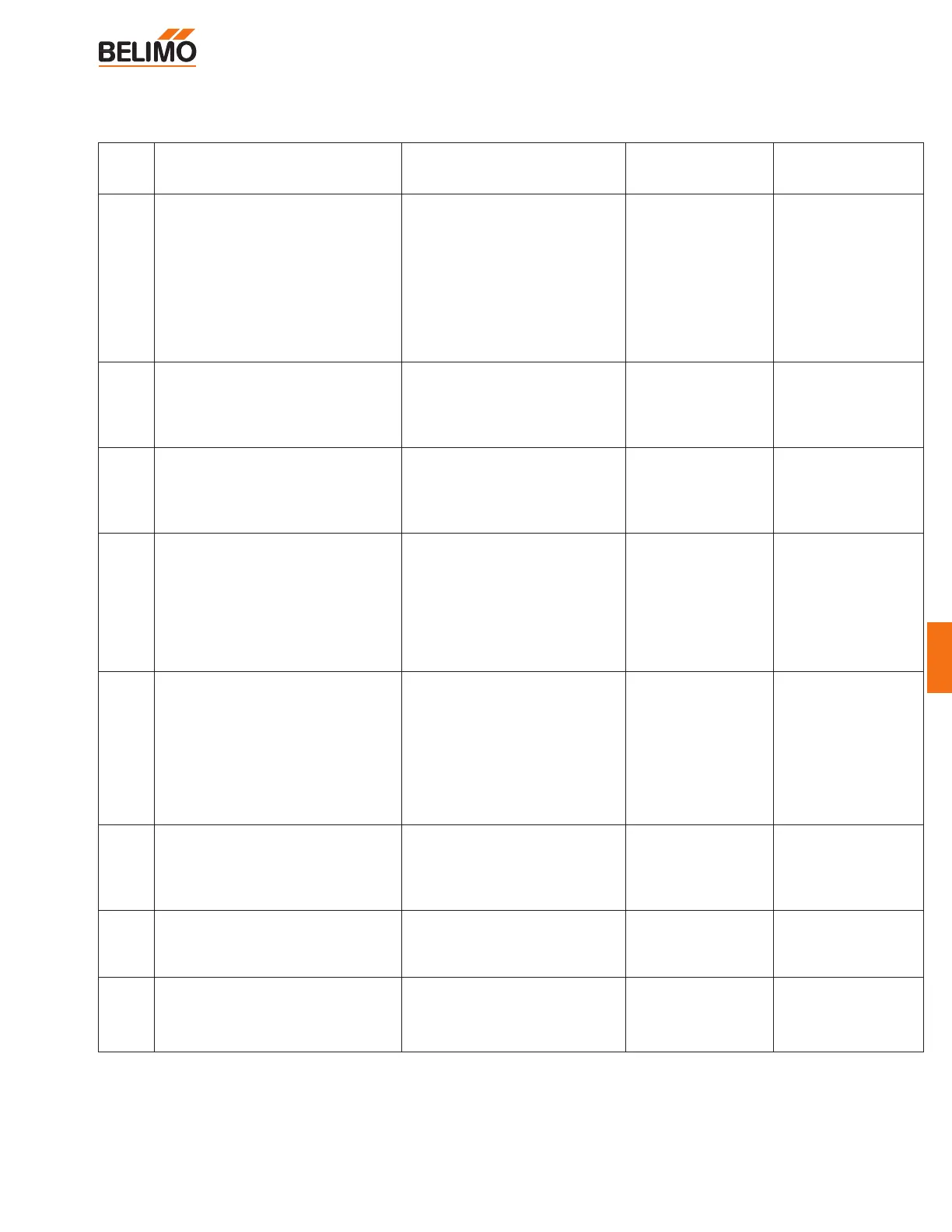

Procedure

Control signal is applied to actuator.

Check power wiring. Correct any

problems. See Note 1.

Turn reversing switch to the correct

position.

Make sure the control signal positive

(+) is connected to Wire No 3 and

control signal negative (-) is connect-

ed to wire No. 1. Most control prob-

lems are caused by reversing these

two wires. Verify that the reversing

switch is all the way CCW or CW.

Check input signal with a digital volt

meter (DVM). Make sure the input is

within the range of the actuator. For

LM24-SR (-T) US this is 0 to 10 VDC

or 0 to 20 mA.

Note: The input signal must be above

the 2 VDC or 4 mA to have the actua-

tor move.

Use the manual override button to

move the damper by hand from fully

closed to fully open.

Check damper torque requirement.

Actuator works properly. Test con-

troller by following controller manu-

facturer's instructions.

Expected Response

Actuator will move to its “Control

Signal” position.

Power supply rating should be

≥

the total power requirement of

the actuator(s). Minimum volt-

age of 19.2 VAC or 21.6 VDC.

Actuator will move to its “Control

Signal” position.

Drives to “Control Signal” posi-

tion

Input voltage or current should

be ±1% of what controller's

adjustment or programming indi-

cate.

Damper will go from fully closed

to fully open.

Torque requirement is ≤ actua-

tor’s minimum torque.

Gives Expected

Response

Go To Step…

Actuator operates

properly

Step 8

Power wiring correct-

ed, actuator begins

to drive

Step 1

Actuator operates

properly.

Step 8

Actuator operates

properly.

Step 8

Controller output

(actuator input) is

correct. Input

Polarity Correct.

Step 6

Damper moves

properly

Step 7

Defective Actuator.

Replace Actuator -

See Note 2

Does Not Give

Expected Response

Go To Step…

No response at all

Step 2

Operation is

reversed

Step 3

Does not drive

toward "Control

Signal Position"

Step 4

Power wiring

corrected, actuator

still does not drive

Step 4

Does not drive

toward “Control

Signal Position”

Step 4

Step 5

Reprogram, adjust

repair or replace

controller as needed.

Step 1

Find cause of

damper jam and

repair.

Step 1

Recalculate actuator

requirement and

correct installation.

Step

1.

2.

3.

4.

5.

6.

7.

8.

Note 1 Check that the transformer(s) are sized properly.

• If a common transformer is used, make sure that polarity is observed on the secondary. This means connect all No. 1

wires to one leg of the transformer and all No. 2 wires to the other leg of the transformer.

• If multiple transformers are used with one control signal, make sure all No. 1 wires are tied together and tied to control

signal negative (-).

• Controllers and actuators must have separate 24 VAC/VDC power sources.

Note 2 If failure occurs within 5 years from original installation date, notify Belimo and give details of the application.

LM24-SR (-T) US and LM24-MFT US + P-100… Electrical check-out procedure

Startup and Checkout

Instructions for LM24-SR (-T) US and LM24-MFT US + P-100…

Loading...

Loading...