6 720 611 447 GB (03.11)

Converting the appliance to different gas types

33

8 Converting the appliance to different gas types

The setting is factory sealed at maximum. Adjustment to

the rated heat input and min. heat input is not neces-

sary.

Checking the gas supply pressure

B Check the gas supply pressure at the gas supply

pressure testing point.

Natural gas

•Appliances for natural gas type G20 are factory set

to Wobbe-Index 15 kWh/m

3

and 20 mbar supply

pressure and sealed.

8.1 Setting the gas/air ratio

The gas/air ratio may only be adjusted on the

basis of a CO

2

measurement at max. heat output

and min. heat output using an electronic tester.

B Switch off the appliance at the master switch (O).

B Remove the outer case (see page 14, refer to

fig. 13).

B Switch on the appliance at the master switch (I).

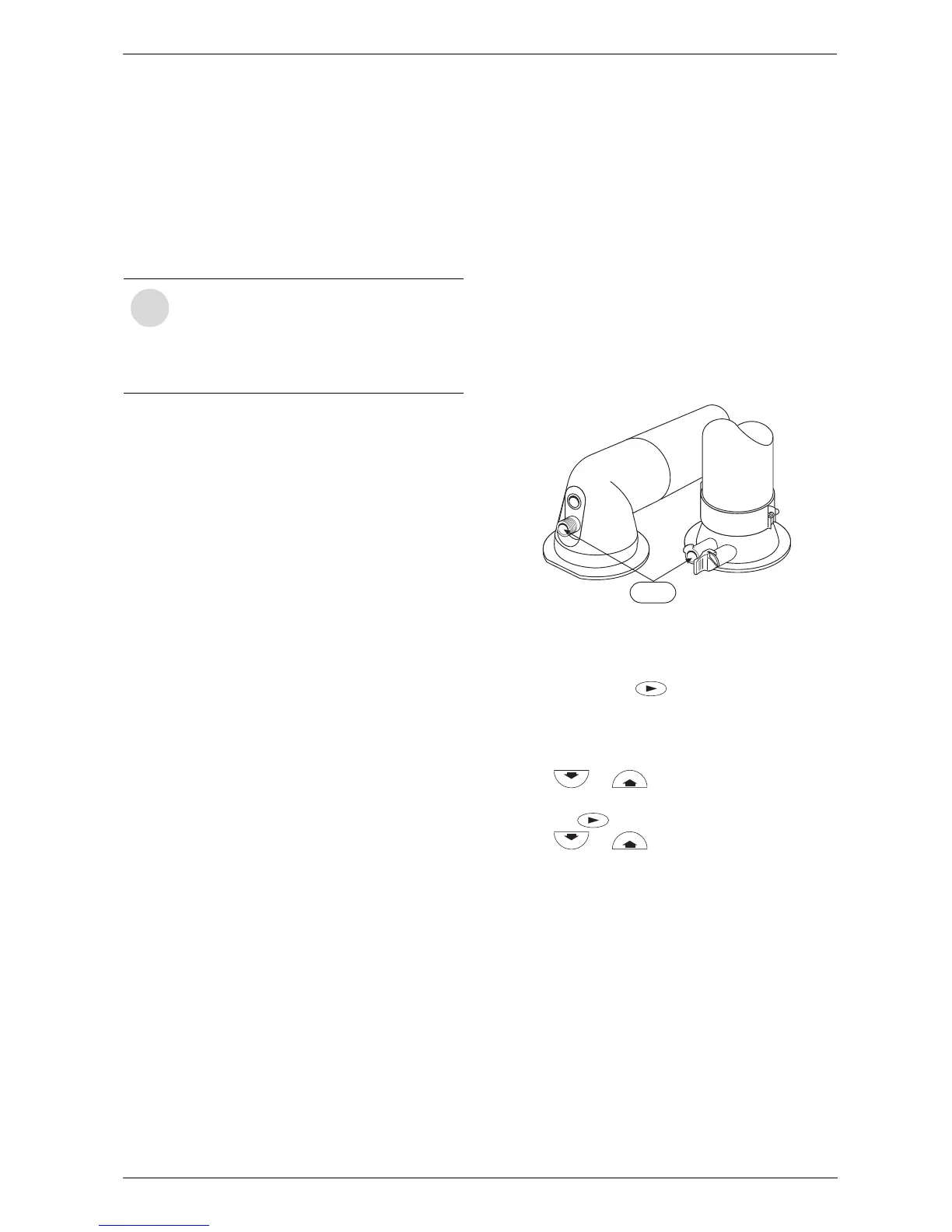

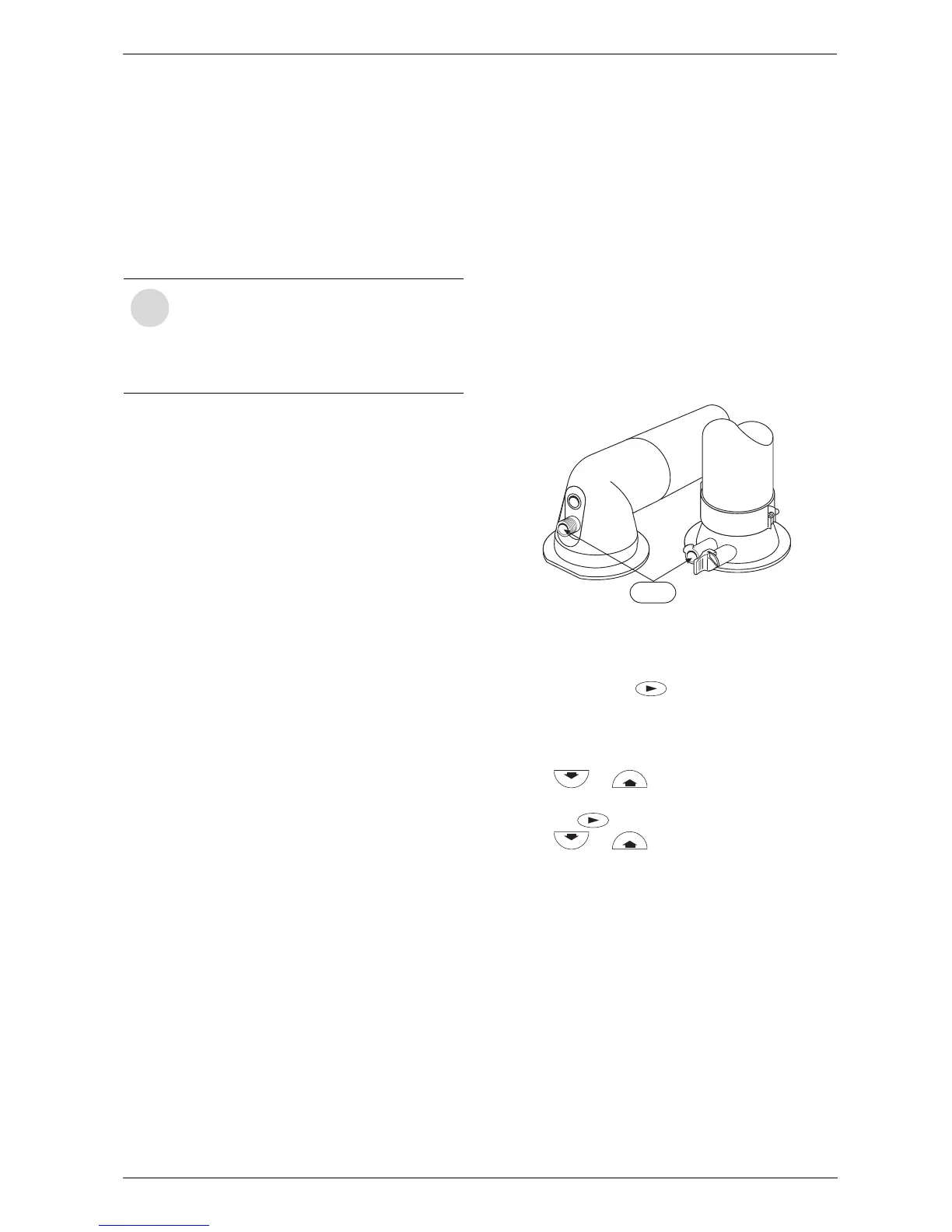

B Unscrew sealing plug from flue gas testing

point (234). Refer to fig. 42.

B Insert testing probe about 135 mm into the flue gas

testing point and seal testing point.

Fig. 42

B On the text display unit, select in the main menu Set-

tings, Service, Display service parameters.

B Press and hold the button (for about 5 sec-

onds) until the display shows Adjust service

parameters and the first service function to be set,

2.0 Operating mode. If a fault has occurred, the

display will show 0.0 and the last fault.

B Press or until the display shows 2.0

Operating mode normal.

B Press the button.

B Press or to select Max.

B Measure the CO

2

level.

B Prise off the seal on the gas flow restrictor.

B Adjust the gas flow restrictor (63) to obtain the CO

2

level given in Table 15. Refer to fig. 43

i

Natural gas appliances must not be oper-

ated if the gas supply pressure is below

18 mbar or above 24 mbar.

LPG appliances must not be operated if

the supply pressure is below or above

37 mbar.

6 720 610 599 - 01.TD

234

Loading...

Loading...