_____________________________________________________________________________________

8300-088 AeroCruze 110 Installation Manual

Rev 1 Page 7

© Honeywell International Inc. Do not copy without express permission of Honeywell.

extended parallel to the primary cable is approximately 3/16” from the primary cable. If the

primary control travel does not exceed 5” the cable locking pin will be 180 away from the

point at which the cable leaves the capstan. When the primary control is at the neutral point

this means the total cable wrap around the capstan is 360. If the primary control travel is

greater than 5” the cable wrap is 720and the pin is adjacent to the output point when the

primary control is at the neutral point.

The cable clamps when properly installed will not slip and thus get loose, but it is desirable to

NICO press or swedge a fitting on to the cable so as to provide added assurance that the cable

will not become slack. If the bridle cable is not sufficiently tight there will be lost motion in the

autopilot drive. This will result in hunting (oscillation).

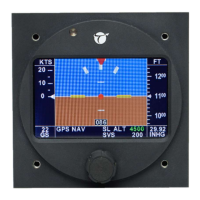

4 CONTROLLER INSTALLATION

4.1 Mounting Considerations

The xCruze 110 autopilot controller unit is designed to mount in the aircraft instrument panel within

view and reach of the pilot. Maximum recommended viewing angle should be no more than 20 deg. The

maximum mounting angle the xCruze 110 can accommodate is 10 degrees longitudinal (pitch) axis and 0

degrees lateral (roll or yaw) axis. The location should be such that the controller unit is not blocked by

the glare shield on top, or by the throttles, control yoke, etc. on the bottom. Use aircraft installation

standards for mounting and support of the controller.

4.2 Wiring Considerations

Use AWG #24 or larger wire for all connections unless otherwise specified. The standard solder pin

contacts supplied in the connector kit are compatible with up to AWG #18 wire. In cases where some

installations have more than one component sharing a common circuit breaker, sizing and wire gauge is

based on length of wiring and current draw on units. In these cases, a larger gauge wire such as AWG

#20 may be needed for power connections. Do not attach any wires to the outside of the programmer

or route high current wires within six (6) inch of the controller. Ensure that routing of the wiring is not

exposed to sources of heat, RF or EMI interference. Check that there is ample space for the cabling and

mating connectors. Avoid sharp bends in cabling and routing near aircraft control cables. Do not route

the COM antenna coax near any autopilot components.

4.3 Pitot and Static Connections

All multi-servo TruTrak autopilots require connections to the pitot and static lines. The ports on the back

of the autopilot are standard 1/8 NPT size. A single wrap of thread tape is recommended. The

preferred method of this connection would be tee fittings near the aircraft’s altimeter. The static line for

the autopilot requires due care in its construction, as excessive lag or insufficient static orifices can

cause the autopilot to oscillate (hunt) in pitch. Although there is compensation within the autopilot

sufficient to handle moderate amounts of lag, the importance of a good static port and line cannot be

overstated. In some cases, problems can be caused by having a large number of devices (including the

autopilot) connected to a single, insufficient, static port. In other cases, the static line itself is adequate

but there are one or more devices connected to the same line, one of which has a large static reservoir.

Loading...

Loading...