Doc No. 20-45-159 Page 10 of 60

It is necessary to provide an automatic means to safely inhibit

heater(s) operation should mechanical air supply fail for any

reason

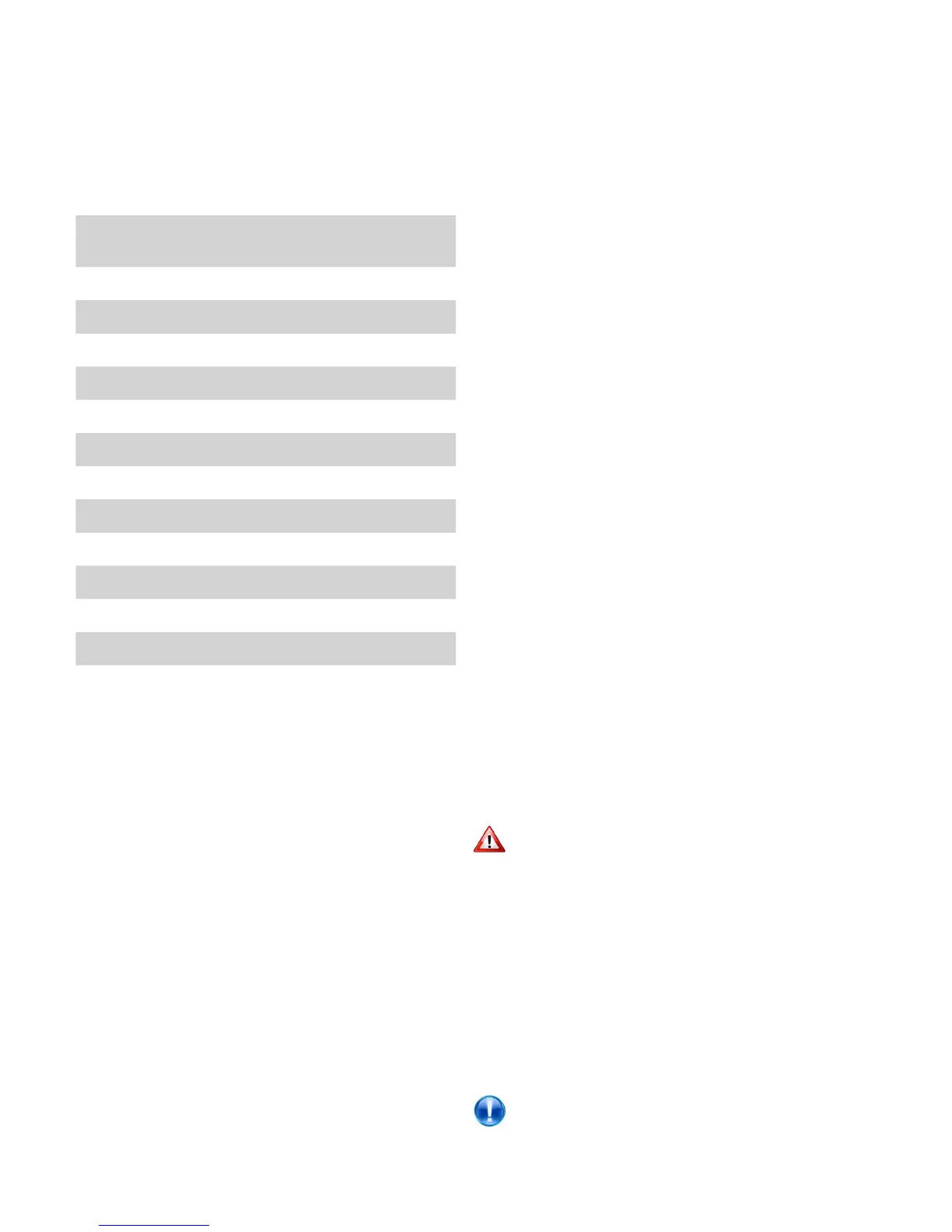

The table to follow provides specic data for each heater

model as -

Mechanical Ventilation Rate

for Plant Room or Enclosure

Model M³/h

30 139

40 206

60 274

85 409

120 567

135 717

180 822

205 987

235 1131

300 1410

375 1830

1.12 Air distribution system

All materials used within the construction of the delivery and

return air ducts must not represent a re hazard and should

be made from thermally inert materials. The selection of

materials must take account of the environment into which

the heater and its air delivery system is expected to work, it

must also take account of the stresses and loadings placed

upon it during its normal working life. Where interjoist spaces

are used to route ducting these must be lined with re

resistant insulation material.

In installations where forced recirculation is a feature, a full

and unobstructed return air path to the heater(s) must be

provided, with return air grilles connected by ducting directly

to the return air inlet on the heater.

The limit for recirculation should not be greater than 85%

re-circulated air to 15% fresh air.

Where the heater is installed within a compartment or plant

room the return air and discharge air arrangement must be

such that the air circulation fan does not interfere with the

operation of the ue.

The return air intake and warm air outlet should therefore be

fully ducted to and from the heater, respectively, within the

compartment or plant room.

If the inlet air is ducted to the outside, then the lowest edge of

the inlet air duct must be at least 500mm above the outside

oor or ground level, it must also be tted with an access

point(s) to allow for cleaning and servicing to occur.

The openings in the structure of the plant room, through

which the ductwork passes must be of re resistant material

and constructed to prevent the likelihood of any re from

spreading.

In ducted applications the ductwork must be designed so as

to give a static pressure within the limits stated in section 15 of

this manual. It should be noted that if the static pressure is too

high, nuisance shut-down will occur when the heater goes out

on the overheat limit thermostat, if the static pressure is too

low, then damage can be caused to the fan motor.

Warm air outlets on ducted applications must be such that

they cannot be closed or become blocked, which again would

lead to an increase in static pressure and nuisance shut-down.

The outlets must not be sited so that warm air can be

discharged onto combustible materials, if necessary, guard

rails should be used to ensure that eected areas are kept

clear.

Return air intakes must not be located so that potentially

harmful or hazardous contaminated air can be drawn into the

system.

1.13 Flue system.

Warning

It is essential that the products of combustion are ued to

the outside of the building. Each heater must have its own

separate ue, with a ue diameter of not less than is detailed

in section 15 within this manual.

The minimum vertical length of ue must not be less than

3m. The ue should rise vertically, and the number of bends

should be kept to a minimum.

Flue pipes below a height of 2m should be guarded against

the possibility of being accidentally touched when hot by

personnel

Note:

It is strongly advised that BS 5854; 1980, and BS 5440; parts 1

Loading...

Loading...