12

put the ramp of the gas valve back in place and screw the nut

reposition the previously removed components

power up the boiler and open the gas tap again.

Adjust the boiler as explained in paragraph “3.9 Adjustments” and paragraph

“3.10 Gas valve calibration”

.

b

Conversion must be carried out by qualified personnel.

b

After the transformation, apply the new rating plate included in the kit.

3.12 Range rated

Thisboilercanbeadaptedtotheheatingrequirementsofthesystem,infactit

is possible to set the maximum delivery for heating operation of the boiler itself:

power up the boiler

set the parameter

310 Range rated

Set the maximum heating value (rpm) and confirm.

007

.

rpm

007

.

rpm

confirm

MAX

rpm

Record the new set value in the table on the back cover of this manual. For

subsequentcontrolsandadjustments,refertothesetvalue.

b

The calibration does not entail the ignition of the boiler.

The boiler is supplied with the adjustments shown in the technical data table.

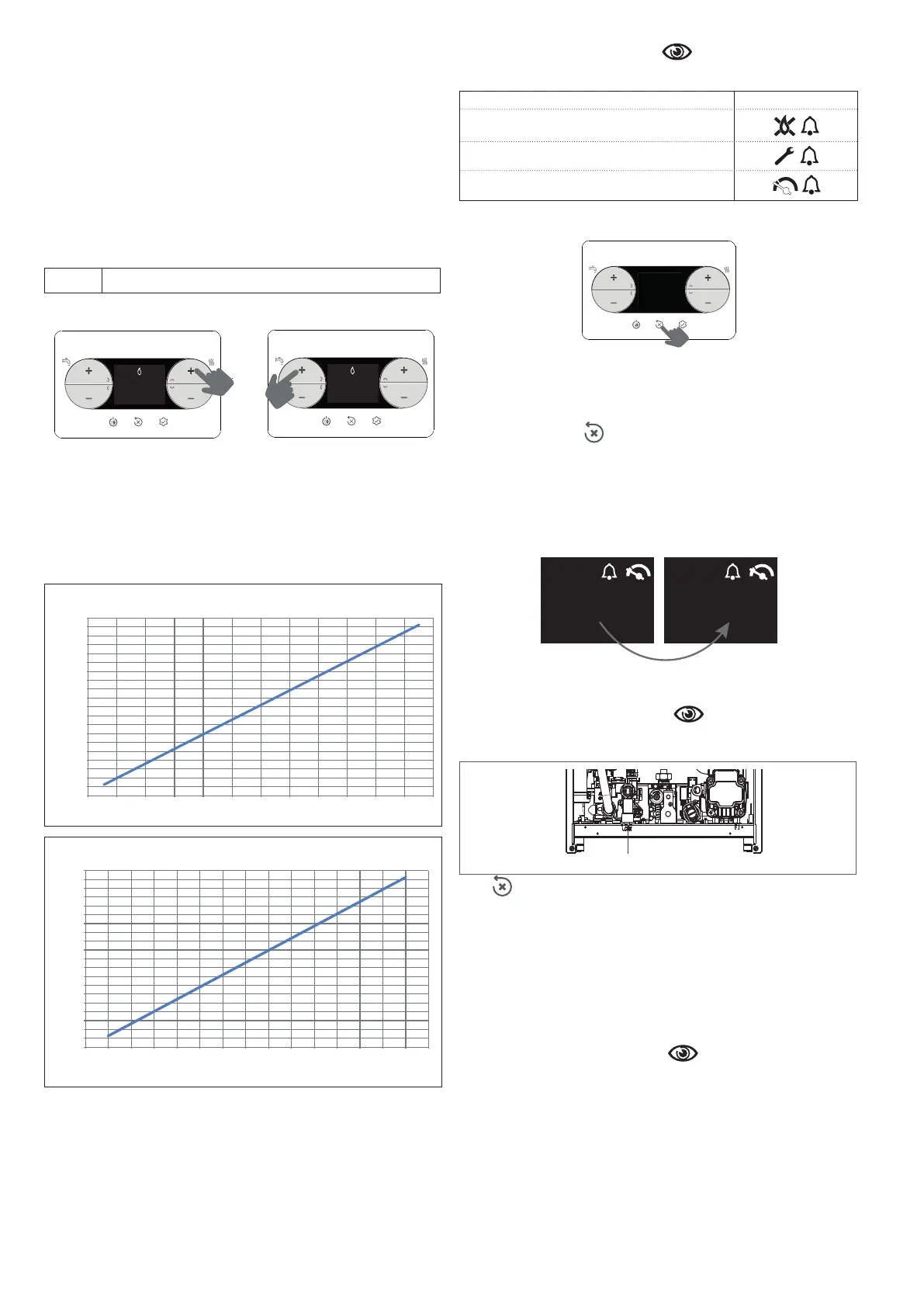

Depending on plant engineering requirements or regional flue gas emission

limitshowever,thisvaluecanbemodifiedbyreferringtothegraphsbelow.

1000

1400

1800

2200

2600

3000

3400

3800

4200

4600

5000

5400

5800

6200

6600

7000

7400

7800

8200

8600

9000

2 4 6 8 10 12 14 16 18 20 22 24 26

Giri ven�latore (r.p.m.)

Portata termica (kW)

Heat input curve - fan rotations - Ciao 25C f

heat input (kW)

1000

1400

1800

2200

2600

3000

3400

3800

4200

4600

5000

5400

5800

6200

6600

7000

7400

7800

8200

8600

9000

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32

Giri ven�latore (r.p.m.)

Portata termica (kW)

Caldaia CIAO 30C f

Heat input curve - fan rotations - Ciao 30C f

heat input (kW)

3.13 Faults and reporting

Ifthereisafault,anerrorcode“Axx”isshownonthedisplay.

Incertaincases,theerrorcodeisaccompaniedbyanicon:

FAULTS ICONS DISPLAYED

amefailureA10

allfaultsexceptamefailureandwaterpressure

water pressure

Reset function

Toresetboileroperationintheeventofafault,press

:

Res

Ifthecorrectoperatingconditionshavebeenrestored,theboilerwillstartup

again automatically

.

Inthepresenceofaremotecontrol,amaximumof5consecutiveunlocking

attempts are available.

Inthiscase,bypressing the boiler restores the initial attempts.

b

Iftheattemptstoresettheboilerdonotwork,contacttheTechnicalAs-

sistance Centre.

Fault A41

Ifthepressurevaluefallsbelowthe0.3barsafetyvalue,theboilershowsthe

fault code A41 for a transitory time of 10 min. If the fault still persists after this

time,faultcodeA40 will appear.

4

A

1 4

A

0

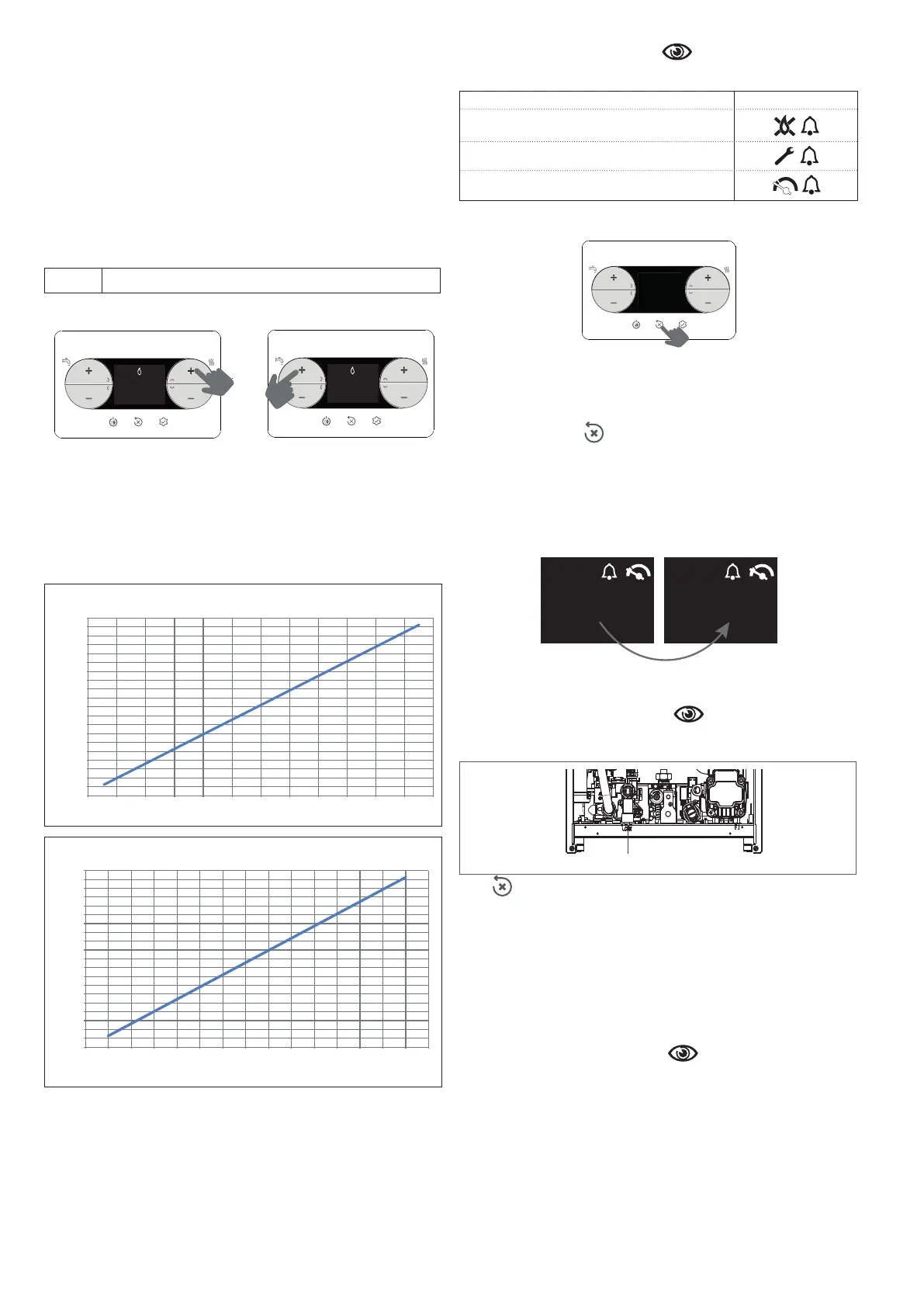

With fault A40 on the boiler it is necessary to:

- openthellingtap(A) turning it counterclockwise

- access the Info menu (

“4.3 INF

O menu ”,itemI018),tocheckthatthe

pressure value reaches 1-1.5 bar

- close thellingtap(A),makingsureyouhearthemechanicalclick.

Press to restore operation. Afterfilling,runaventingcycle.Ifthepressure

dropisveryfrequent,contacttheTechnicalAssistanceCentre

.

Fault A60

Theboilerisworkingnormally,butdoesnotprovideanystabilityofthedomestic

hotwatertemperaturethat,inanyevent,issuppliedatatemperatureofaround

50°C. The intervention of the Technical Assistance Centre is required.

Fault A91

The boiler has a self-diagnosis system that signals the need to clean the primary

heat exchanger on the basis of the total number of hours in certain operating

conditions (alarm code A91).

Fault A91 occurs when the counter exceeds the value of 2500 hours; this value

can be checked in the “4.3 INFO menu ”,itemI015(visualization/100,

example 2500h = 25)

Aftercleaning(usingthespecialkitsuppliedasanaccessory),resetthetotal

hours counter by bringing parameter 312 = 1.

NOTE: The meter resetting procedure should be carried out after each in-dep-

th cleaning of the primary exchanger or if this latter is replaced.

3.14 Replacing the board

Ifthecheckandadjustmentboardisreplaced,itmaybenecessarytorepro-

gramtheconfigurationparameters.Inthiscase,refertotheparameterstable

toseetheboarddefaultvalues,thefactorysetvalues,andthepersonalised

values

.

The parameters that must be checked and reset if necessary after repla-

cing the board are

: 301 - 302 (SERVICE) - 306 - 307 - 308 - 309 - 310.

Loading...

Loading...