7

In particular on the boiler display:

- it is no longer possible to set the boiler OFF/WINTER/SUMMER status (it is

set by the OT+ remote control)

- it is no longer possible to set the domestic hot water setpoint (it is set by the

OT+ remote control)

- the combination of the A+B keys remains active for the setting of the DOME-

STIC HOT WATER COMFORT function

- the domestic hot water setpoint (I005) is displayed in the INFO menu

- the heating setpoint value calculated by the OT+ remote control (I017) is

displayed in the INFO menu

- the heating setpoint set on the boiler display is used only if there are heat

requests from the TA and the OT+ remote control does not have a request if

the parameter: 311 = 1 or 311 = 0,butthe VZONE jumper on the adjustment

board is closed. This value is displayed in the INFO menu (I016)

.

- to activate the “Combustion analysis” function with an OT+ remote control

connected,youmusttemporarilydisabletheconnectionbysettingthepa-

rameter 803 = 0 (SERVICE); remember to reset this parameter once the

functionhasnished.

Key 3 remains active for the visualisation of the INFO menu and the enabling

of the SETTINGS menu.

High voltage connections

The connection to the mains supply must be made via a separation device

with an omnipolar opening of at least 3.5 mm (EN 60335/1 - category 3). The

applianceworkswithalternatingcurrentat230Volt/50Hz,andisincompliance

with Standard EN 60335-1. It is obligatory to make the connection with a safe

ground/earth,incompliancewithcurrentdirectives.

b

The installer is responsible for ensuring the appliance is suitably earthed;

the manufacturer will not be liable for any damage resulting from an in-

correct or absent earth connection.

b

It is also advisable to respect the phase-neutral connection (L-N).

b

The earth conductor must be a couple of cm longer than the others.

b

To create the seal of the boiler use a clamp and tighten it on the cable

grommet used.

The boiler can operate with a phase-neutral or phase-phase power supply. It

is forbidden to use gas and/or water pipes to earth electrical appliances. Use

the power cable supplied to connect the boiler to the mains power supply. If the

powercablehastobereplaced,useaHARH05V2V2-F,3x0.75mm²cable,

Ø max external 7 mm.

2.5 Gas connection

The connection of the gas supply must be carried out in compliance with current

installationstandards.Beforecarryingouttheconnection,checkthatthetypeof

gas is that for which the appliance is set up

.

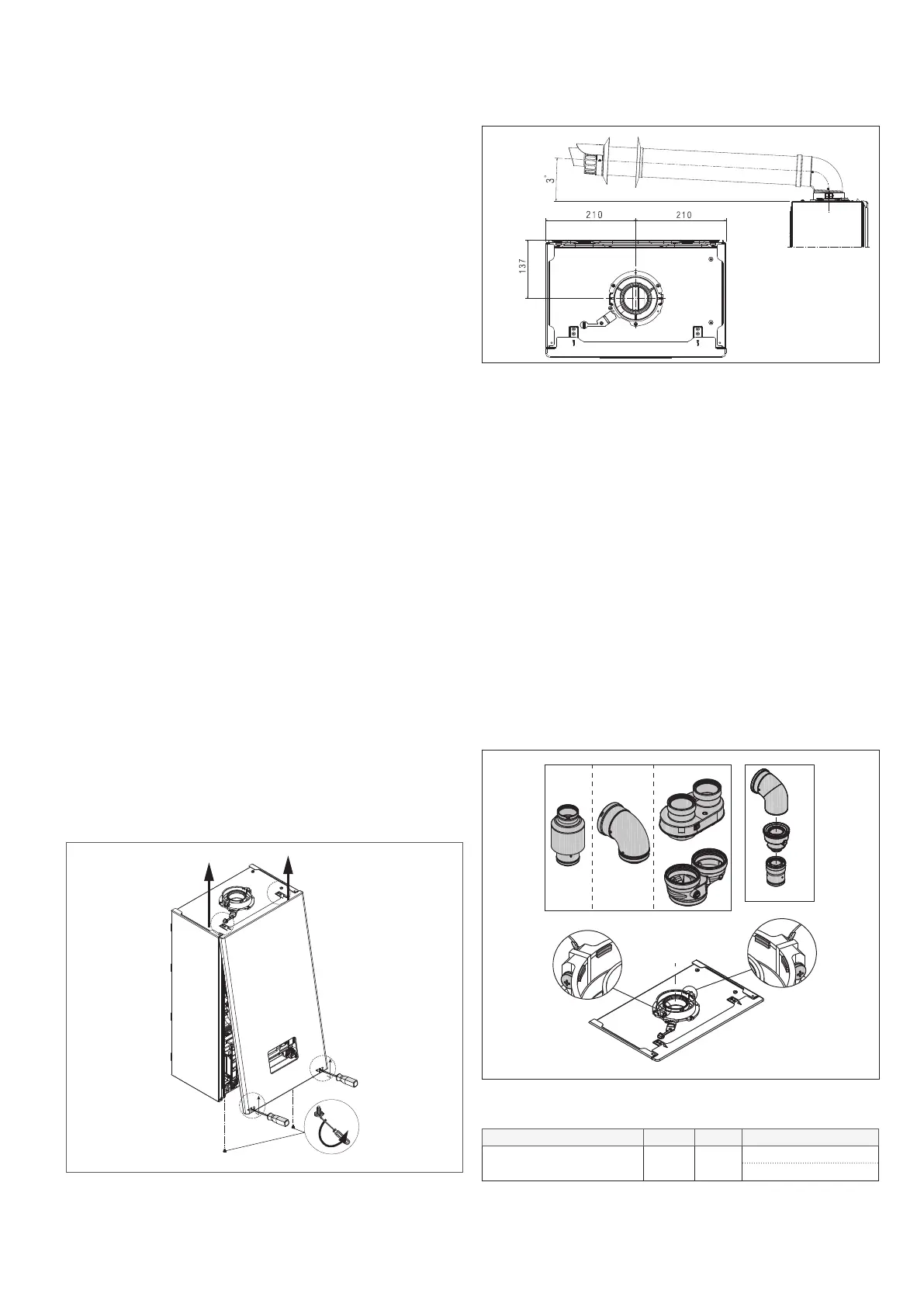

2.6 Removing the casing

Toaccessthecomponentsinside,removethecasingasshowninthegure.

b

Ifremovingthesidepanels,putthembackintheirinitialposition,referring

to the adhesive label on its wall

.

b

If the front panel is damaged it must be replaced

.

b

The noise absorbing panels inside the front and side walls ensure the

airtight seal for the air supply duct in the installation environment

.

b

It is therefore CRUCIAL after the dismantling operations to correctly re-

positionthecomponentstoensuretheboiler’ssealiseective

.

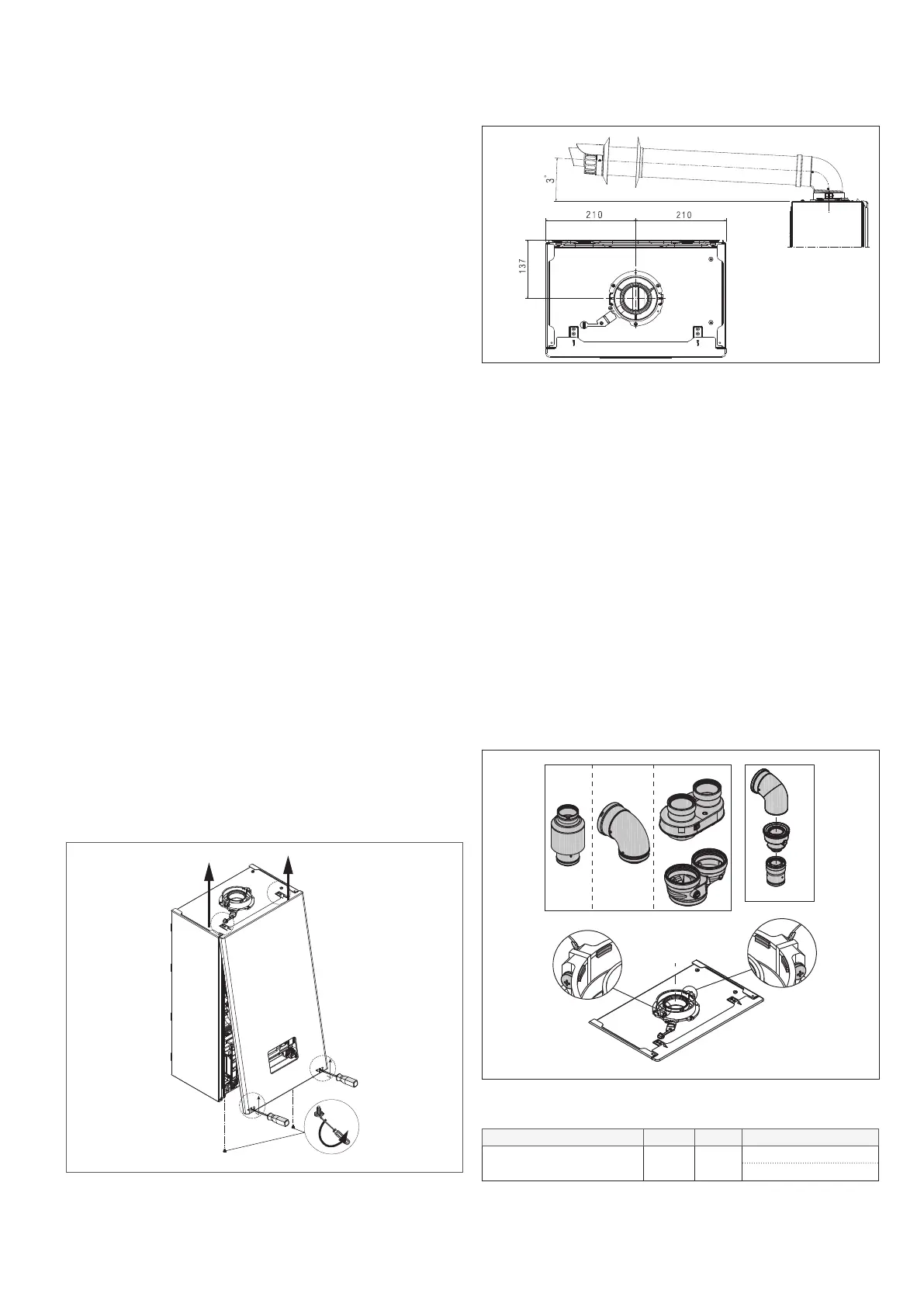

2.7 Flue gas exhaust and combustion air suction

Toevacuatethecombustionproducts,refertoUNI7129-7131.Alwayscomply

withlocalstandardsoftheFireDepartment,theGasCompanyandwithpossi-

ble municipal dispositions.

Itisessentialfortheevacuationoftheuegasesandtheadductionoftheboi-

ler’s combustion air that only original pipes be used (except C6) and that the

connectionismadecorrectlyasshownintheinstructionsprovidedwiththeue

gases accessories

.

Asingleuecanbeconnectedtoseveralappliancesprovidedthateveryap-

pliance is the condensing type.

b

b

“Straightlength”meansfreeofbends,andincludesterminalsandjoints.

b

Theboilerissuppliedwithouttheuegasexhaust/airsuctionkit,sinceit

ispossibletousetheaccessoriesforcondensingappliancesthatbestt

the installation characteristics (see catalogue

).

b

Themaximumlengthsofthepipesrefertotheueaccessoriesavailable

in the catalogue

.

b

Itiscompulsorytousespecicpipes

.

b

Thenoninsulateduegasoutletpipesarepotentialsourcesofdanger

.

b

The use of a longer pipe causes a loss of output of the boiler

.

b

The exhaust pipes can face in the direction most suited to the installation

requirements

.

b

Asenvisagedbycurrentlegislation,theboilerisdesignedtotakeinand

disposeofuegascondensateand/ormeteoricwatercondensatederi-

vingfromtheuegasdischargesystemusingitsownsiphon

.

b

If a condensate relaunch pump is installed, check the technical data

(providedbythemanufacturer)regardingoutput,toensureitoperates

correctly

.

- Positionthedischargepipesothattheconnectionsitsfullyupagainsttheue

gases turret of the boiler.

- Afterpositioningit,makesurethe4notches(A) slip into the groove (B).

- Fully tighten the screws (C)thatholdthetwoangelockingterminals,sothe

bend itself is restrained held in place.

A

A

C

C

B

Ø80-125

B

B

B

B

B23P-B53P Ø60-100 Ø80-80

b

If the Ø 60-100 to Ø 80-80 splitter kit is used instead of the twin pipe

system,thereisalossinthemaximumlengthsasshowninthetable

.

Ø 50 Ø 60 Ø 80

Loss of length (m) 0,5 1,2

5,5foruegasespipe

7,5forairpipe

Twin pipes with Ø 80 pipework (Ø50 - Ø60 - Ø80)

Thankstotheboilercharacteristics,aØ80uegasexhaustpipecanbecon-

nected to the Ø50 - Ø60 - Ø80 piping ranges.

Loading...

Loading...