8

b

Forthepipe,youareadvisedtomakeaprojectcalculationinorderto

respect the relevant regulations in force.

Thetableshowsthestandardcongurationsallowed

.

Air suction

1 bend 90° Ø 80

4.5m pipe Ø80

Flue gas

discharge

1 bend 90° Ø 80

4.5m pipe Ø80

Reduction from Ø80 to Ø50 from Ø80 to Ø60

Fluebasebend90°,Ø50orØ60orØ80

For ducting pipe lengths see table

The boilers are factory set to:

CH rpm DHW rpm Max length pipes (m)

Ø50 Ø60 Ø80

model A

7.000 8.700

6 19 95

1 9 45

model B

7.000 8.700 4 16 80

7.400 8.700 0 7 35

Shouldgreaterlengthsberequired,compensatethepressuredropwithanin-

creaseinther.p.m.ofthefan,asshownintheadjustmentstable,toprovidethe

rated heat input,referring to paragraph

“3.9 Adjustments”

.

b

Theminimumcalibrationshouldnotbemodied.

b

Incaseofnewfanspeedadjustment,carryouttheCO2 check procedu-

re as indicated in paragraph “3.8 Combustion analysis”.

Adjustment tables INSIDE CHIMNEY PIPES

twin ue pipe

Fan rotations rpm Pipes Ø50 Pipes Ø60 Pipes Ø80 ∆P at boiler outlet

CH DHW Maximum length (m)

model A

7.000 8.700 6 19 95 180

7.100 8.800 12 * 33 * 165 * 260

7.200 8.900 16 * 39 * 195 * 300

7.300 9.000 19 * 46 * 230 * 342

7.400 9.100 23 * 53 * 265 * 383

7.500 9.200 27 * 61 * 305 * 431

7.600 9.300 29 * 67 * 335 * 465

7.700 9.400 32 * 73 * 365 * 500

model B

7.000 8.700 4 16 80 180

7.100 8.800 8 * 26 * 130 * 260

7.200 8.900 11 * 32 * 160 * 300

7.300 9.000 14 * 38 * 190 * 342

7.400 9.100 17 * 44 * 220 * 383

7.500 9.200 19 * 50 * 250 * 431

7.600 9.300 22 * 56 * 280 * 465

7.700 9.400 25 * 62 * 310 * 500

(*) Maximum length that can be installed ONLY with class H1 discharge pipes.

compact twin ue pipe

Fan rotations rpm Pipes Ø50 Pipes Ø60 Pipes Ø80 ∆P at boiler outlet

CH DHW Maximum length (m)

model A

7.000 8.700

1

9 45 180

7.100 8.800

7 *

23 *

115

* 260

7.200 8.900

11 *

29 *

145

* 300

7.300

9.000 14 *

36 *

180

* 342

7.400

9.100 18 *

43 *

215

* 383

7.500

9.200 22 *

51 *

255

* 431

7.600

9.300 24 *

57 *

285

* 465

7.700

9.400 27 *

63 *

315

* 500

model B

7.400 8.700 0 7 35 190

7.500

8.800

4 *

17 *

85

* 256

7.600

8.900

7 *

23 *

115

* 300

7.700

9.000

10 *

29 *

145

* 340

7.800

9.100

13 *

35 *

175

* 380

7.900

9.200

15 *

41 *

205

* 417

8.000

9.300

18 *

47 *

235

* 458

8.100

9.400

21 *

53

* 265

* 500

(*) Maximum length that can be installed ONLY with class H1 discharge pipes.

TheØ50orØ60orØ80congurationscontainLabtestdata.Intheeventof

installationsthatdierfromtheindicationsinthe“standardcongurations”and

“adjustments”tables,refertotheequivalentlinearlengthsbelow.

b

Inanycase,themaximumlengthsdeclaredinthebookletareguarante-

ed,anditisessentialnottoexceedthem.

COMPONENT Linear equivalent in metres Ø80 (m)

Ø 50 Ø 60

Bend 45° 12,3 5

Bend 90° 19,6 8

Extension 0.5m 6,1 2,5

Extension 1.0m 13,5 5,5

Extension 2.0m 29,5 12

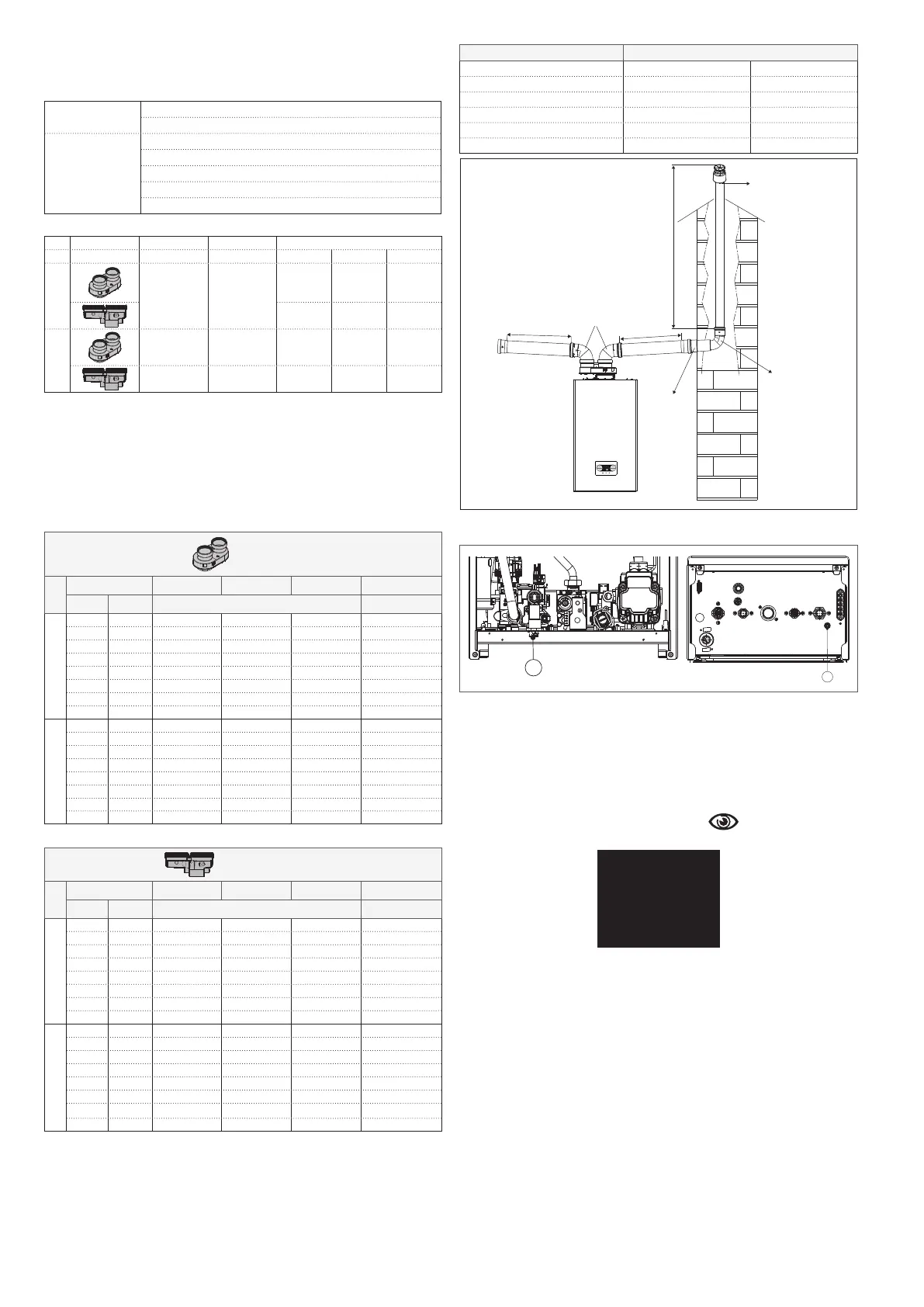

chimney for ducting

ø 50 mm or ø 60

mm or ø 80 mm

length

90° bend ø 50

mm ø 60 mm

or ø 80 mm

80-60 mm or

ø 80-50 mm

reduction

90° bends ø 80 mm

4,5m Ø 80mm

4,5m Ø 80mm

°

C

508

.

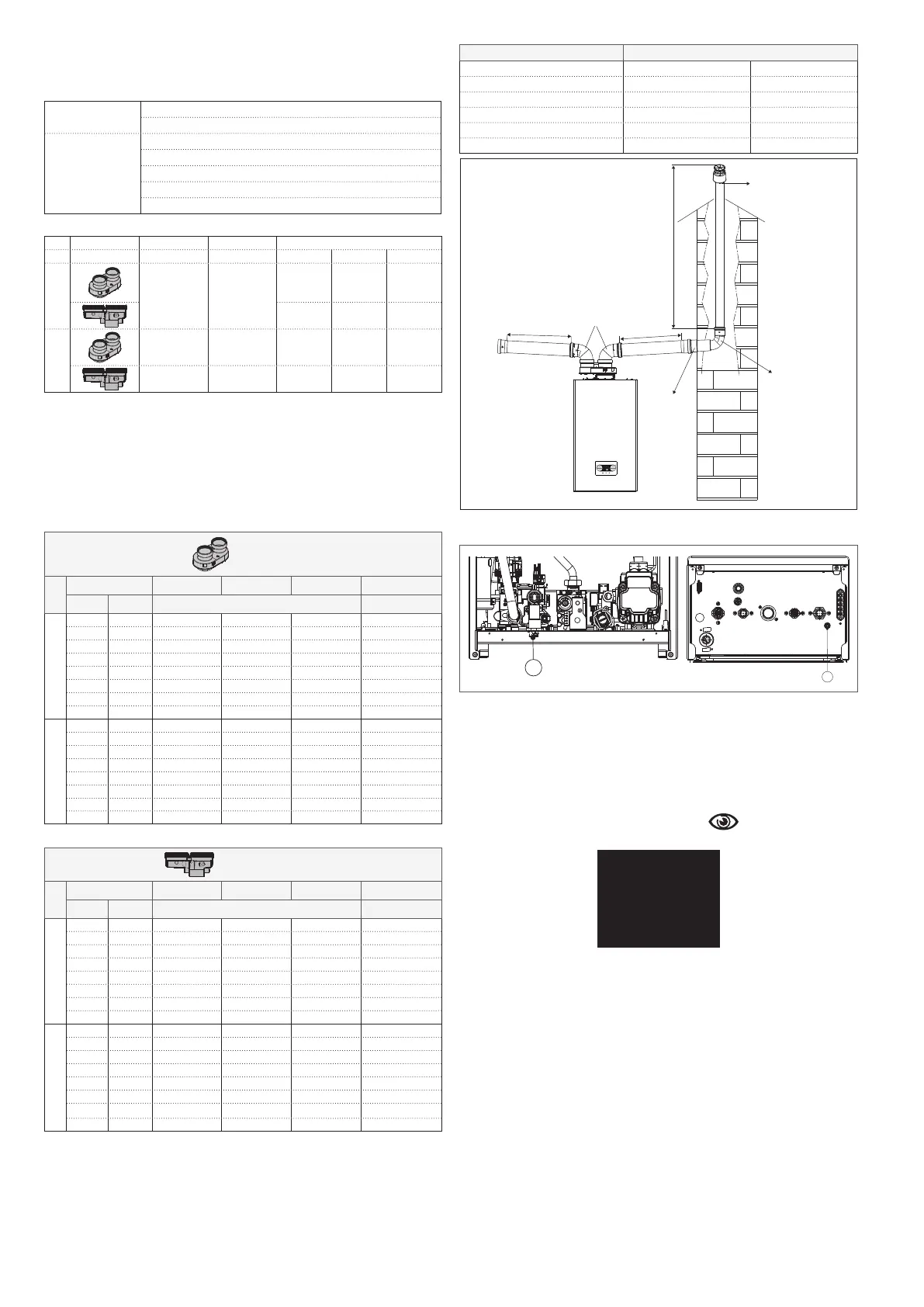

2.8 Filling the heating system and eliminating air

C

A

NOTE: llthesystemviathellingtap(A) making sure the boiler is electrically

powered.

NOTE:eachtimetheboilerispoweredup,theautomaticventingcycleiscar-

ried out.

NOTE: the presence of a water alarm (A40,A41orA42) does not allow the

venting cycle to be carried out.

Fill the heating system as follows:

- openthellingtap(A) turning it counterclockwise

- then access the Info menu (

“4.3 INF

O menu ”,itemI018),tocheck

that the pressure value reaches 1-1.5 bar

.1

5

.

NOTE: ifthemainspressureislessthan1bar,keepthellingtap(A) open

during the venting cycle. Close it when the cycle has ended.

To start the venting cycle:

- switchotheelectricalsupplyforafewseconds

- connectthepoweragain,leavingtheboilerOFF

- check that the gas tap is closed.

At the endofthecycle,ifthecircuitpressurehasdropped,openthellingtap

(A) again to bring the pressure back up to the recommended value (1-1.5 bar).

The boiler is ready after the vent cycle.

- Remove any air in the domestic system (radiators, zone manifolds, etc.)

using the bleed valves.

- Once again check that the system pressure is correct (ideally 1-1.5 bar) and

restore the levels if necessary.

- Ifairisnoticedwhenoperating,repeattheventcycle.

- Oncetheoperationsarenished,openthegastapandignitetheboiler.

At this point it is possible to carry out any heat request.

2.9 Draining the heating system

Beforedraining,settheboilertoOFFandshutotheelectricalsupplysetting

thesystem’smainswitchto“o”

.

- Close the heating system’s taps (if present

).

Loading...

Loading...