24 / 49

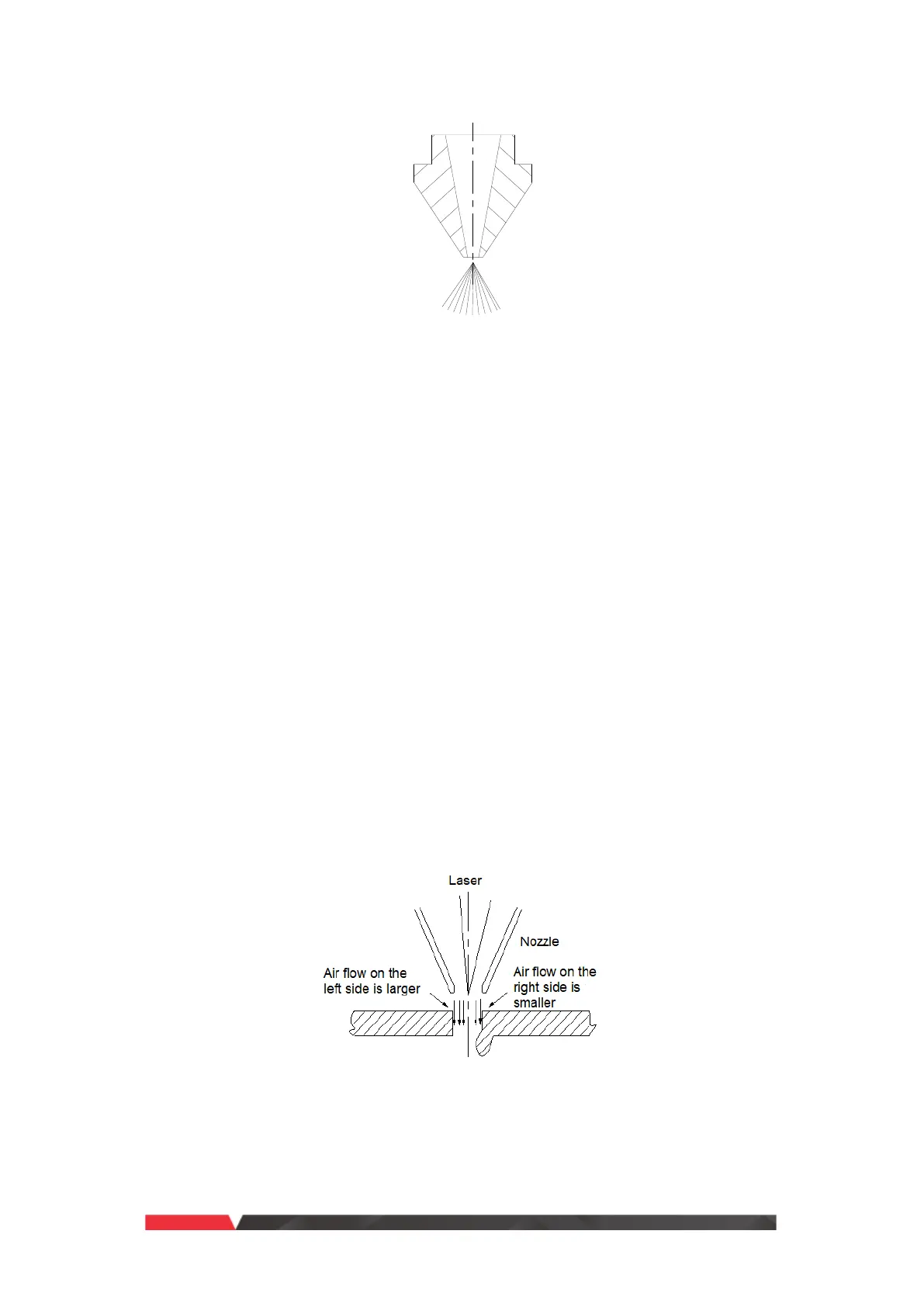

Figure 2 The Condition of Gas Spraying with a Cutting Torch

6.3.2 The relationship between the cutting torch and cutting quality

1. The coaxiality between the outlet hole center of the cutting torch and laser beam is one of

the key factors affecting cutting quality. The thicker the workpiece is, the greater the effect

will be.

2. The coaxiality will be affected when there is any deformation or melting stain on the cutting

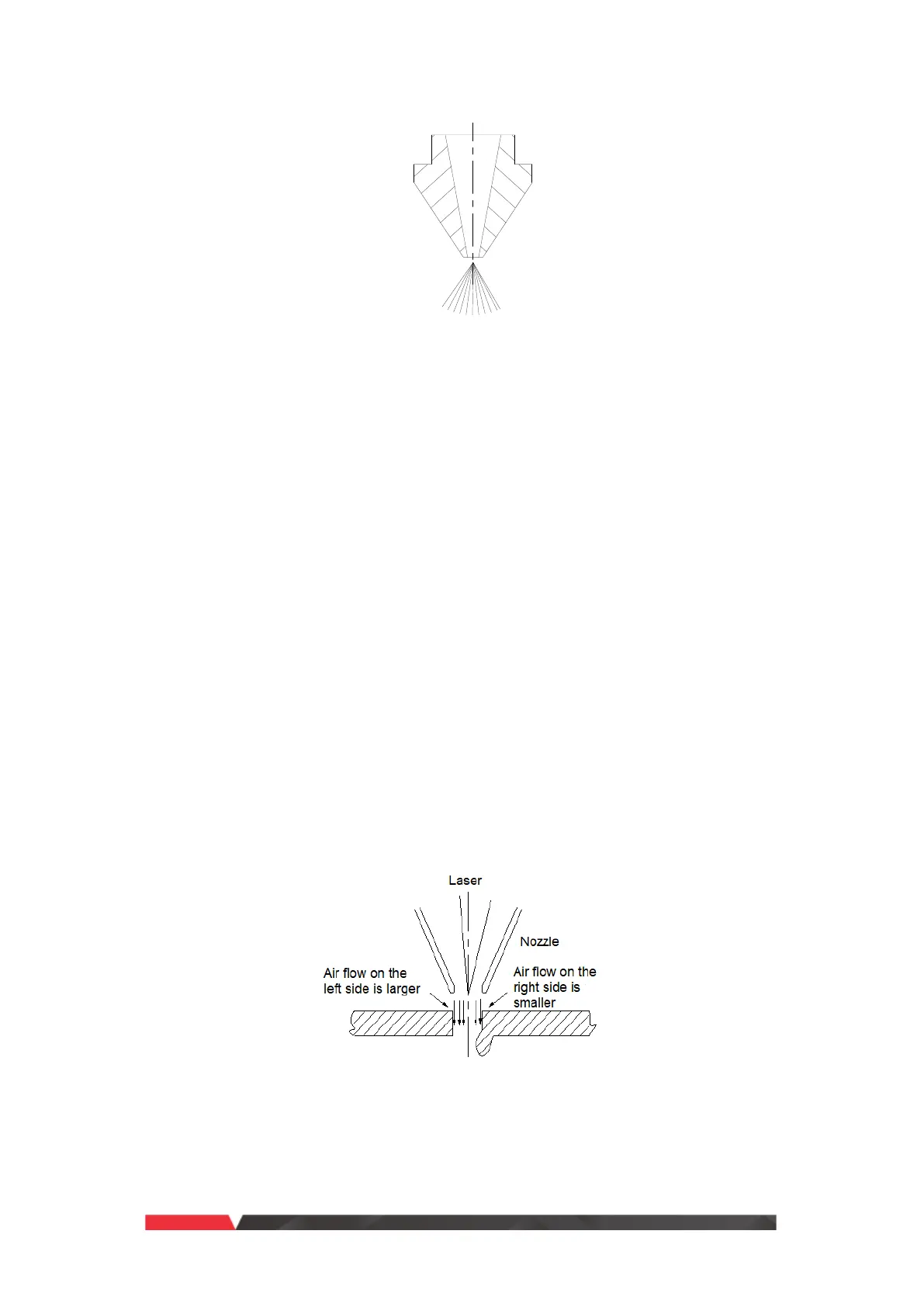

torch.

3. A careful preservation of cutting torch is required in case of deformation due to bump injuries.

Mount correctly considering the high manufacturing precision of the cutting torch shape and

dimension.

4. If the cutting torch is in poor condition and cutting parameters have to be changed

accordingly, the replacement of a brand-new cutting torch is preferred.

5. If the cutting torch is not same with laser in coaxiality, it will have the following effects on the

cutting quality.

6. Effect on cut surface

7. Shown as "Figure 3", when auxiliary gas sprays out from the cutting torch, the air flow is

uneven, and the phenomena occurs with one side melt stained and the other side not. There

is a little effect when cutting thin plate with thickness less than 3mm, while there is a severe

effect with thickness greater than 3mm and sometimes the plate cannot be cut through.

Figure 3 Coaxiality Influence on Cutting Section

Loading...

Loading...