25 / 49

6.3.2.1 Influence on sharp corner

It is easy to cause super fusion if there is sharp corner or smaller angle on workpiece, and

thick plate may not be cut.

6.3.2.2 Influence on piercing

Unstable piercing and time control difficulty may cause super fusion to thick plates, and it's

difficult to control penetrating conditions. Influence on thin plates is relatively smaller.

6.3.3 Adjustment of cutting torch holes and laser beam coaxiality

Refer to the section about operation of automatic focusing cutting head.

6.3.4 Pore diameter of the cutting torch

Pore diameter size of cutting torch has critical influence on cutting quality and piercing quality.

If the pore diameter of cutting torch is too large, the slag spattering area is larger during

cutting, and the cutting surface of thick plate is relatively coarse; on the contrary, if cutting torch

diameter is too small and cutting speed is slow, it will easily generate adhering slag.

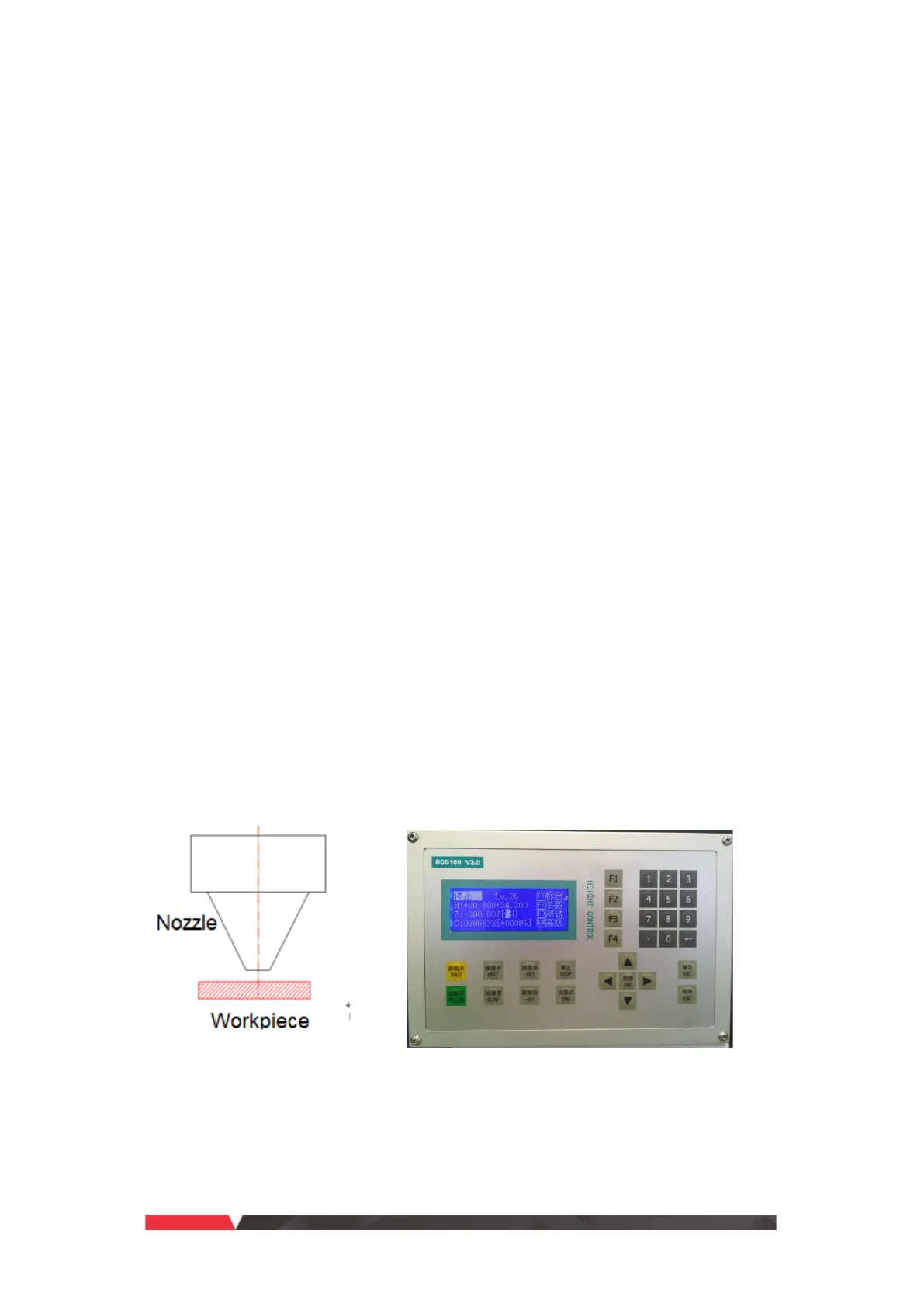

6.4 Adjustment of cutting torch height

Cutting torch height is the distance from cutting torch outlet to workpiece surface.

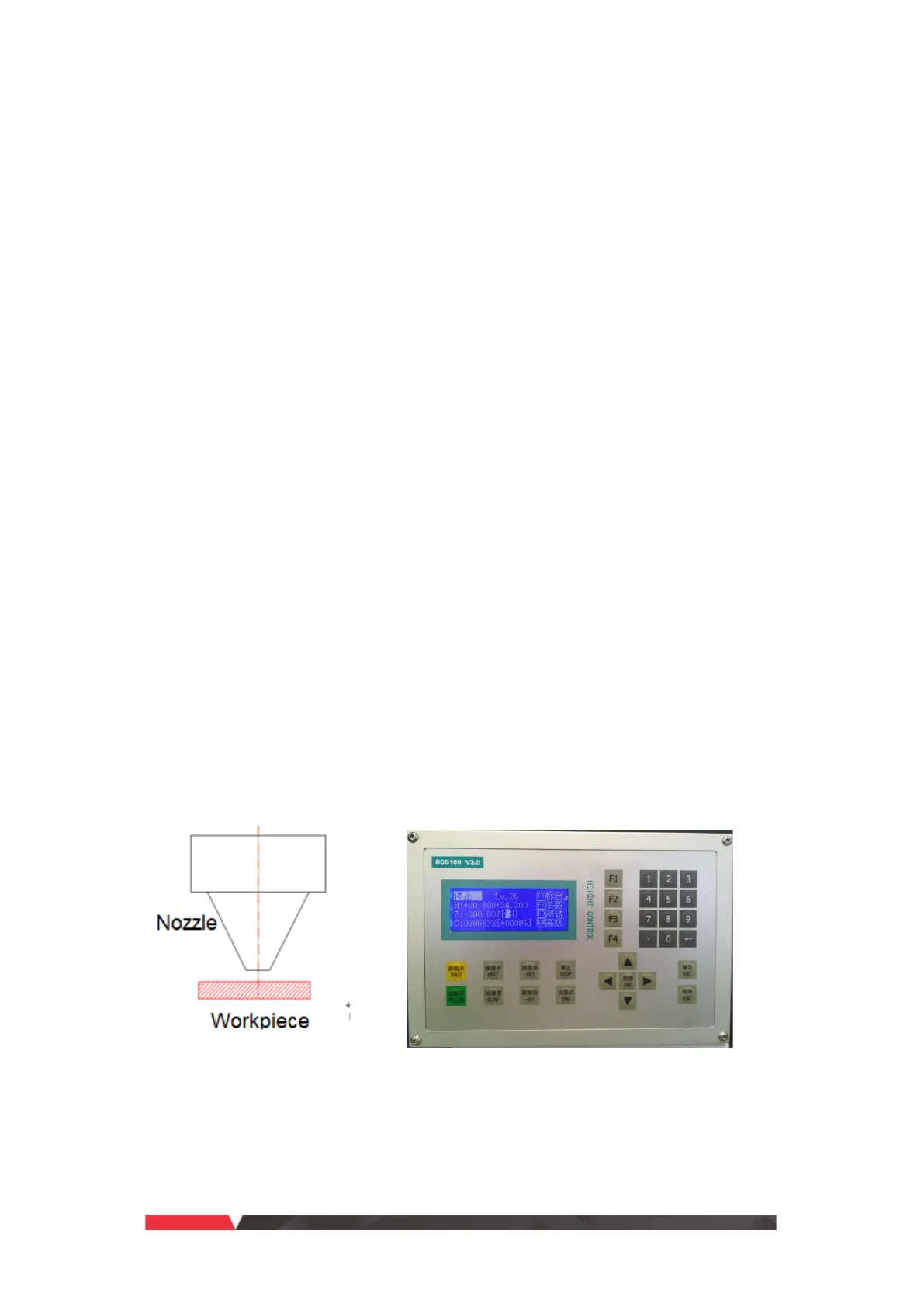

Figure 4 Height of the Cutting Torch Capacitor box (BSC100)

After completing calibration, input appropriate piercing and cutting height into

program parameter base.

Loading...

Loading...