Fig. 5.1

3.5 Acoustic noise

Sound pressure levels amounting to 70 db(A) are not normally

exceeded on the machine operation site.

3.6 Vibrations

The machines are equipped with vibration-proof rubber feet.

In standard working conditions, the machines do not generate

dangerous vibrations, neither for the operator nor for the envi-

ronment.

3.7 Machine functional specications and make up

TheoverallSoaEspressorangeisavailableinthefollowingcon-

gurationversions:

Semi-automatic version:

· With 1 steam dispenser nozzle and 1 hot water dispenser pipe

(GROUP 1)

· With double Steam dispenser nozzle and hot water dispenser

pipe (GROUPS 2 - 3)

· With boiler water level display (GROUPS 1-2-3)

Automatic version:

· With or without machine operation display functions.

· With 1 Steam dispenser nozzle and 1 hot water dispenser pipe

(1 GROUP)

· With double Steam dispenser nozzle and hot water dispenser

pipe (GROUPS 2 - 3)

· With boiler water level display (GROUPS 1-2-3).

4. TRANSPORT

4.1 Packing

The machine is delivered in one single cardboard package, with

internal expanded polystyrene safety padding inserts.

The packing is provided with conventional symbols to be accurately

observed during package handling and storing operations.

During transport the package must be kept in a consistently ver-

tical position.

Do not turn upside down or onto one side.

Transport carefully avoiding bumps and impacts and exposure to

bad weather.

4.2 Inspection on delivery

Upon delivery, check to see that the machine complies exactly with

the description provided on the transport documents, accessories

included.

Check to see that the machine has not been subject to transport

damages. If it has, immediately report the occurrence to the

forwarder as well as to our customer service department.

Potentially hazardous machine packing material must strictly not

be left on hand for access by children.

Do not disperse the packing material in the environment but en-

sure that it is accurately disposed of via appropriate packing and

waste recycling facilities.

5. INSTALLATION

Themachinesarettedwithheight-adjustablefeet.Ensurethat

height is adjusted identically for all the four base feet.

The positioning support surface must be evenly levelled, dry,

strong and stable, to be positioned at a height of at least 110 cm

fromtheoor.

For correct machine operations it is not necessary to anchor it to

the support surface and neither are technical devices required to

limit vibrations.

It is hereby recommended that some free space is left all around

the machine, to make use and maintenance operations quick

and easy

Do not install the machine if it is wet or moist and wait until the

machine is surely and completely dry. Prior inspections by the

service personnel are anyway necessary, to warrant that the ma-

chine’s electrical components are not damaged.

Make sure that enough space is left in the vicinity of the machine

for positioning of the dose-grinder coffee.

In the event that the machines are equipped with a water treat-

ment unit, said unit must be hooked up by the installation per-

sonnel in full compliance with all the existing laws and regulations

in force.

In the event of installation of different water treatment units not

specicallydedicatedtothemachine,makesurethatallthere-

lative product documentation is completely observed.

Have the installation personnel install a coffee grounds collector

tray.

5.1 Utilities to be provided by the customer

All the utility connection operations must be conducted by

qualied personnel, in full compliance of the federal, state

and/or local rules and regulations in force.

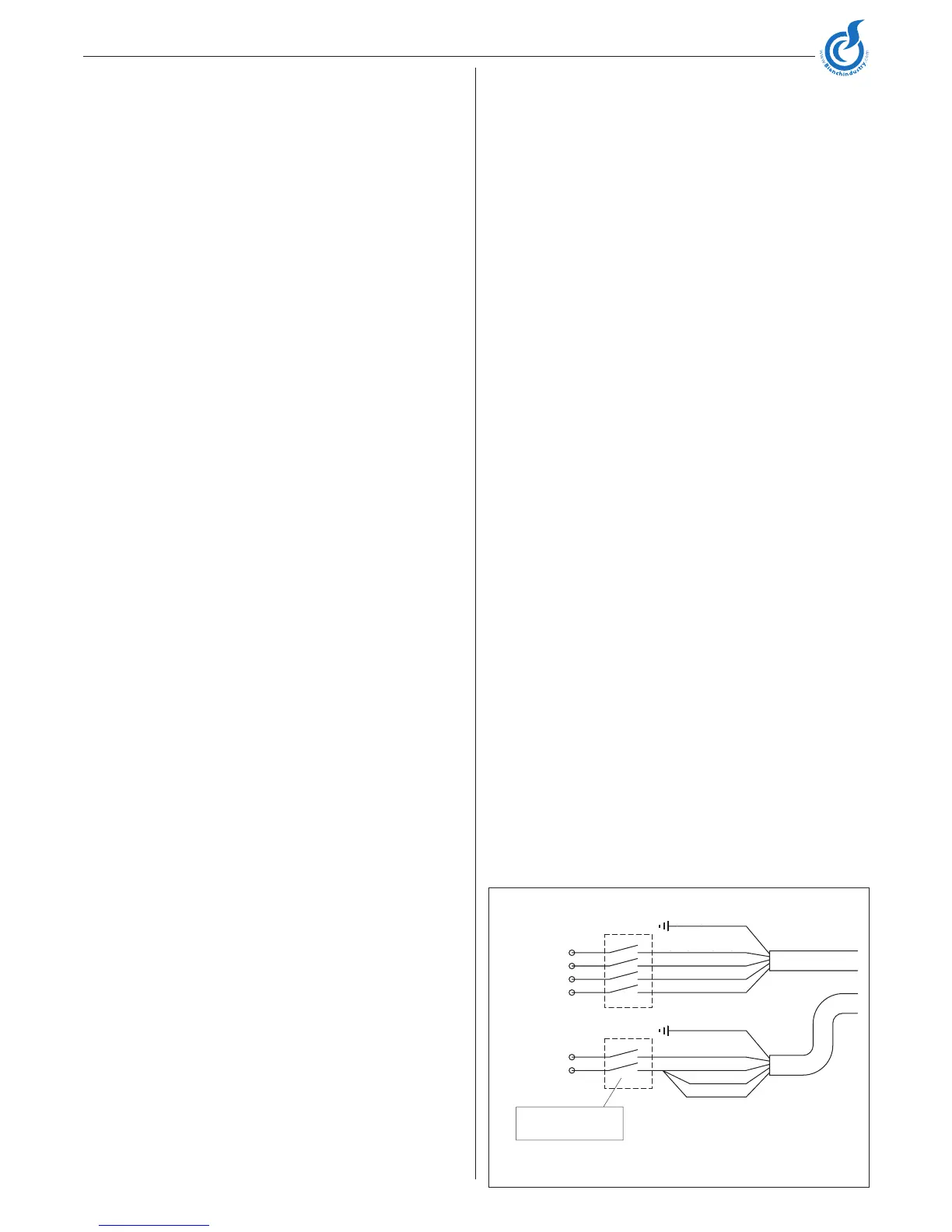

5.1.1 Power supply

The machine is supplied ready for connection to the on-site

power mains according to the specications requested upon

purchasing.

Prior to connecting up the machine, check to ensure that the rating

plate data is compliant with the power mains voltage data. The

power supply cable, that must be wholly undamaged, must be

hooked up directly into the previously prepared utility connections

as per all the rules and regulation in force. The grounding and at-

mospheric overload discharge safety and protection systems must

mandatorily be executed as per all existing laws and regulations.

For connection to the power mains, implement only an up-to-stan-

dard cable, provided with a safety (grounding) conductor.

For the three-phase power supply, use a 5 conductor (3-phases

+ neutral + ground) connector.

For the single-phase power supply, use a 3 conductor (3-phases

+ neutral + ground) connector.

YELLOW GREEN

NEUTRAL BLUE

220V BROWN

220V GREY

220V BLACK

THREE-PHASE

POWER SUPPLY

SINGLE-PHASE

POWER SUPPLY

CIRCUIT BREAKER

DEVICE, SUITED TO

OVERLOAD CAT. 3.

YELLOW GREEN

NEUTRAL BLUE

220V BROWN

GREY

BLACK

ELECTRIC POWER SUPPLY

CABLE

Loading...

Loading...