10

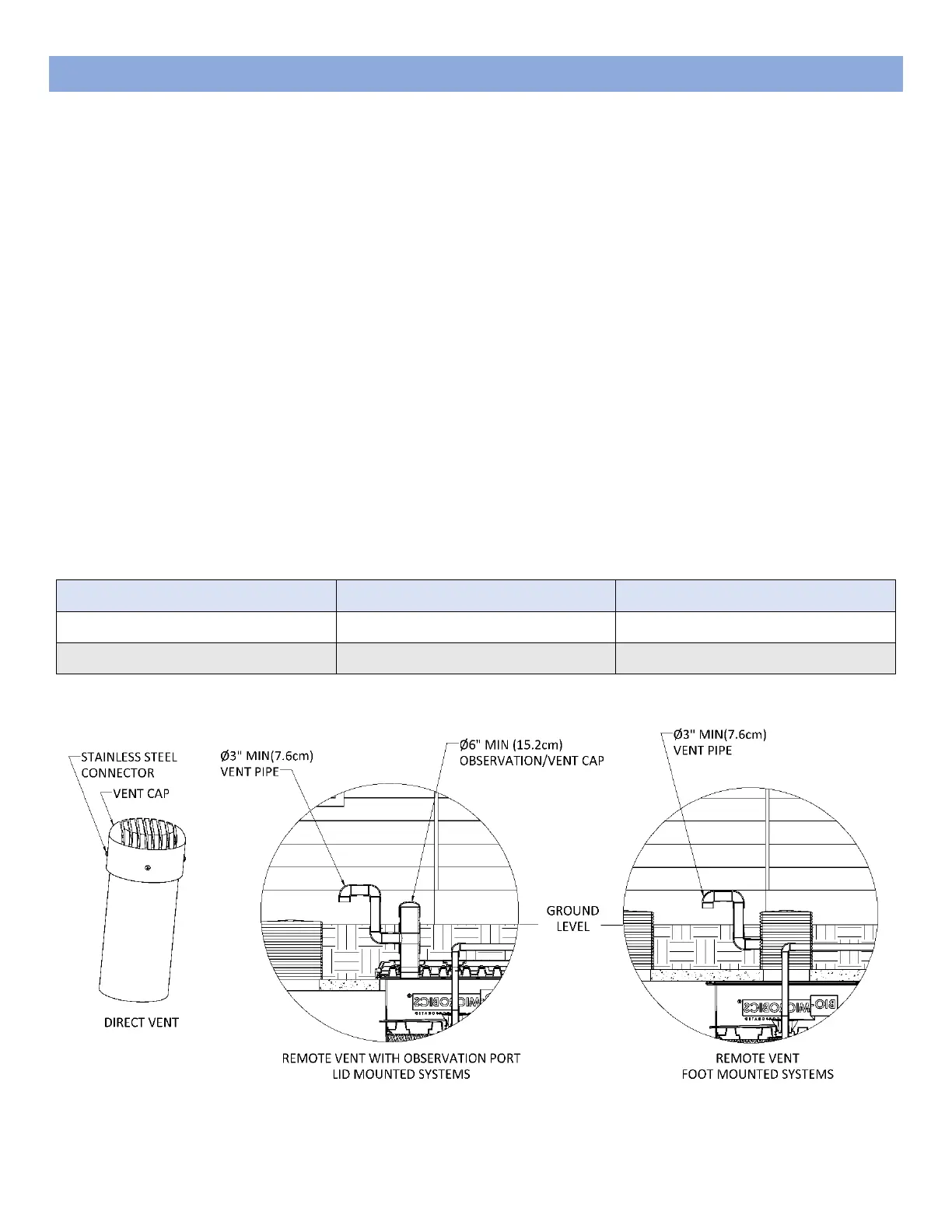

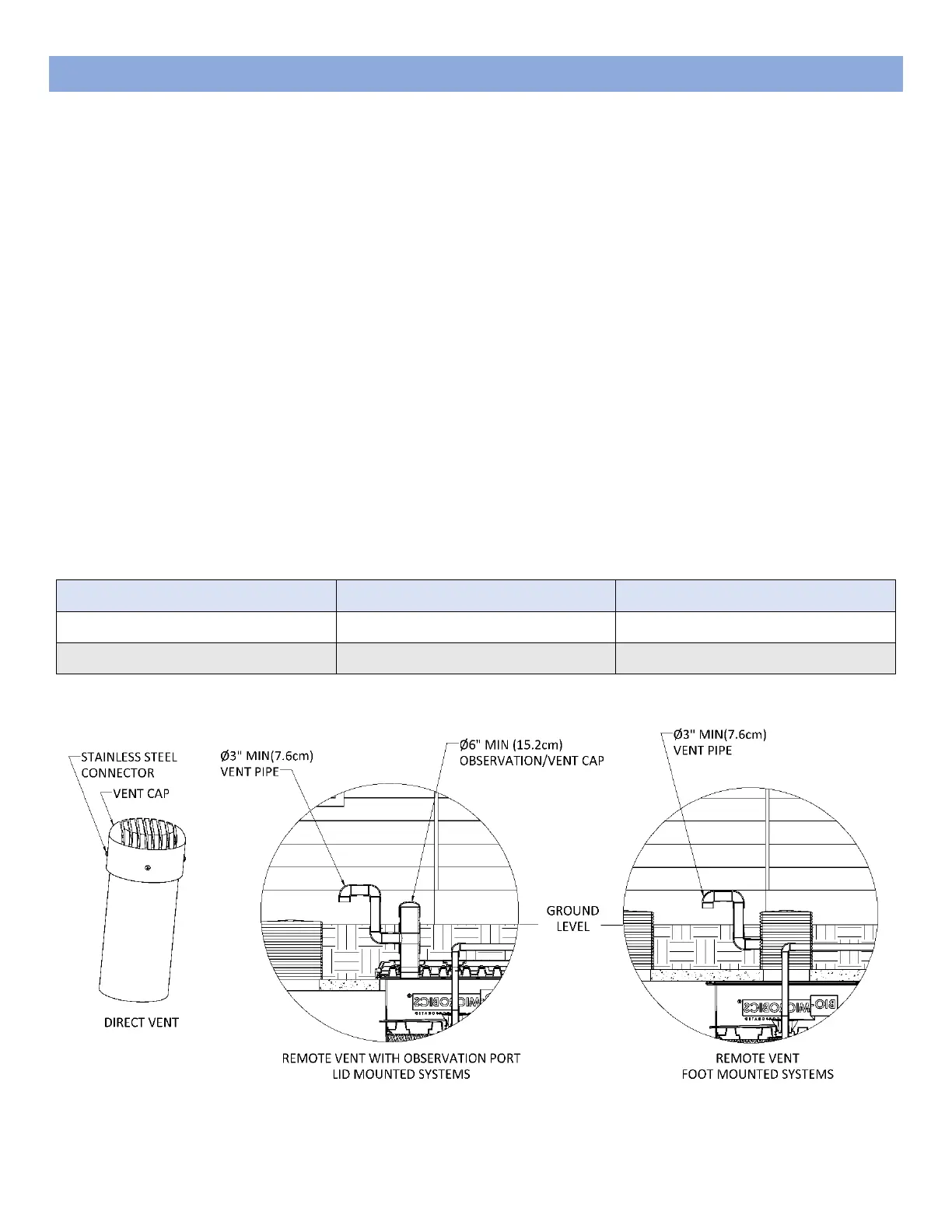

VENTING

There are several options for proper venting. Four of the most common are mentioned here. The vent system

must be sized properly to avoid excessive back pressure in the system (see table below). It must not allow

surface water to enter the system and must allow internal condensation to drain.

DIRECT VENT: The 6” observation port can be used as a vent by capping with a slotted cap or above-

ground elbow. Any cap must be fastened with screws to prevent unauthorized access. The opening(s)

should prevent foreign material from entering the system. Make sure vent cap or fitting is removable

for observation purposes.

OBSERVATION / VENT PORT: For lid-mounted systems, insert 6” PVC pipe through factory-provided

gasket into the lid until it stops. Use screws to secure observation cap.

REMOTE VENT: Branch off of the 6” observation port or manhole below grade. Run the vent pipe to

the desired location and terminate above grade. Cover opening with #4 mesh screen or similar. Water

accumulating in the vent piping must be drained to prevent back pressure. NOTE: The vent should not

exceed 100 ft [30.5 m] in length.

BIOFILTER: Please contact BioMicrobics for guidance on how to build a buried vent using wood chips

and pipe. (BioFilter not shown).

0.5, 0.625, 0.75, 0.9, 1.0, 1.5

2

2

3.0 6 in [15.3 cm]

2

[

2

Loading...

Loading...