22

Installing the rear wheel

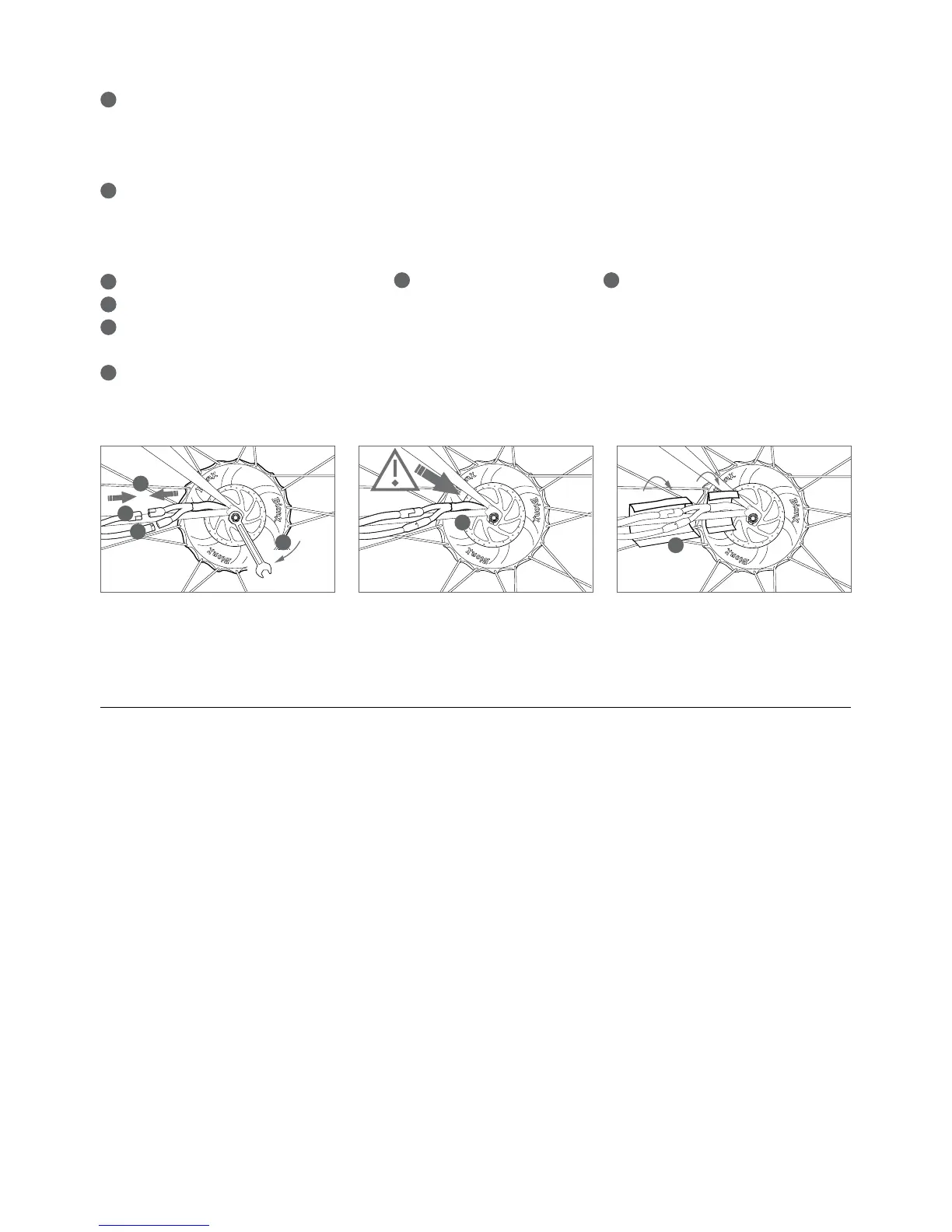

1

Guidetherearwheelaxleintothedropoutsandmakesurethatthebrakedisc(onmodelswithdisc

brakes) is inserted between the brake pads. Also make sure that the flat area at the left of the rear axle

(torquereactioncollar)isalignedsothatittsintotheleftdropout(noillustration).Makesuretheaxle

is inserted all the way in the dropouts

2

Tightentheaxlenutsontherearwheelwith40Nm/30lb-ft(=VERYTIGHT!).Thistorqueisessential

for the correct function of the propulsion system. If you do not have a torque wrench, use a normal

ringwrench.Haveyourdealercheckthetorqueoftheaxlenutsasquicklyaspossible.Useonlythe

original axle nuts; otherwise you run the risk of damaging the axle threads

3

Pluginthecableconnections(POWER

A

beforeCOMMUNICATION

B

)

4

Keepthemotorcablesclearofthebrakedisc(onmodelswithdiscbrakes)andthemotorcasing

5

Nowreplacethecablepull.Re-installthecableguideoftherearwheelbrake(rimbrakesonly),and

correctlyadjusttherearwheelbrake(noillustration)

6

Place the larger neoprene cover over the plug-in connections, and the smaller neoprene cover closer to

thedisc/motortopreventthecablesfromwear

Maintenance and Care

We recommend to have the spoke tension of the rear wheel and the torque of all screws checked by your

qualieddealeraftertherst200km(125miles).

In order to ensure extended use of the propulsion system, all plug-in contacts of the system should be

checked every two to three months and cleaned with a soft and dry brush, if necessary. It must be ensured

that no dirt or humidity penetrates the battery docking station when the battery is removed. The electric

motor is a brushless DC-motor that does not have to be serviced.

15mm

Loading...

Loading...