DB-200-56

3.2 Conformity

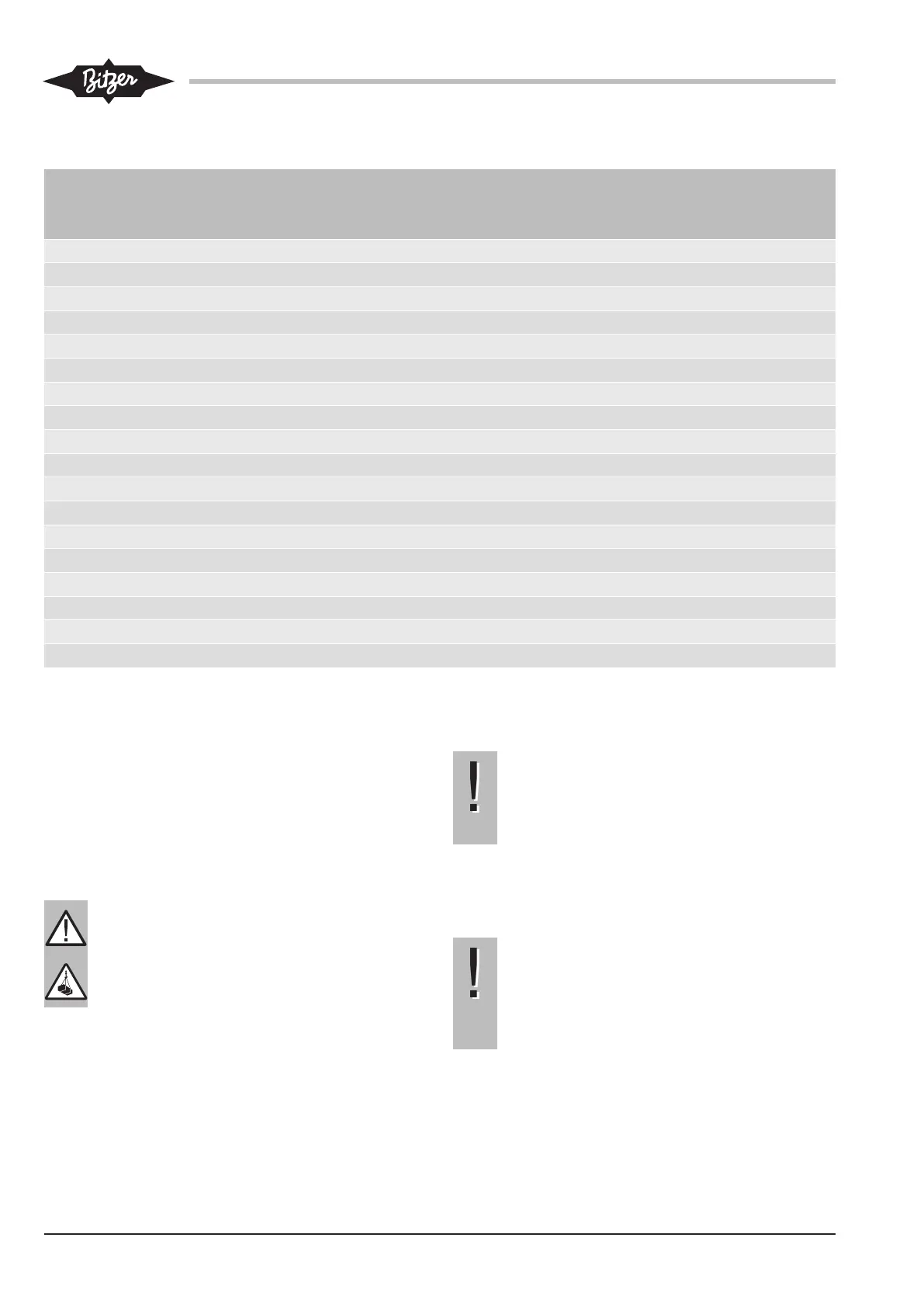

Type Reservoir fluid capa-

city

dm

3

(l)

Category according

to 2014/68/EU (PED)

Fluid group 2

Category according

to 2014/68/EU (PED)

Fluid group 1

Conformity assess-

ment depending on

the module

K033N/H(P)(B) 3.8 I II A2

K073H(P)(B) 3.4 I II A2

K123H(P)(B) 5.1 I II A2

K203H(P)(B) 11.8 II III B + D

K283H(P)(B) 11.3 II III B + D

K373H(P)(B) 14.5 II III B + D

K573H(P)(B) 29.4 II III B + D

K813H(P)(B) 27.7 II III B + D

K1053H(P)(B) 40.0 III IV B + D

K1353T(P)(B) 37.0 III IV B + D

K1973T(P)(B) 76.0 III IV B + D

K2923T(P)(B) 67.0 III IV B + D

K3803T(P)(B) 108.0 IV IV B + D

K4803T(P)(B) 98.0 III IV B + D

OW401(B) 10.5 II III B + D

OW501(B) 14.0 II III B + D

OW781(B) 18.0 II III B + D

OW941(B) 24.0 II III B + D

Tab.3: Category and evaluation of conformity

4 Mounting

4.1 Transporting the pressure vessel

Transport the pressure vessel screwed on a pallet. Lift

it using the eyebolts or the upper fastening brackets if

available.

DANGER

Suspended load!

Do not step under the machine!

4.2 Installation location

For outdoor installation, take suitable measures to pro-

tect the pressure vessel against corrosion (e.g. caused

by seawater or aggressive atmosphere) and low out-

side temperatures. Consultation with BITZER is recom-

mended.

NOTICE

Danger of freezing!

It is necessary to ensure that the temperature at

the location is high enough above the freezing

point of the coolant.

4.3 Plant design

If a compressor is mounted on the condenser:

NOTICE

No vibrations should be transmitted to the con-

denser!

Do not use the condenser as load-bearing ele-

ment! Mount the compressor on the condenser

only with damper elements!

The discharge line must be sufficiently elastic so that a

minimum of vibrations and movement is transferred to

the condenser. It may be necessary to fit flexible vibra-

tion dampers.

Loading...

Loading...