ure 2 shows a typical example. The power supply

offers overload protection; therefore, any fuse in the

equipment’s power cable is not required during

testing. In fact, a convenient connection point may

be to the fuseholder. Normally, the equipment chas-

sis should be grounded. Usually, the negative po-

larity of the equipment is common with the chassis

and a jumper may be connected between the

(*

)

and

(-)

terminals of the power supply.

In those cases where the chassis is not common

with the negative polarity, connect a separate test

lead free from the

(

-h-

)

terminal of the power supply

to the chassis of the equipment being serviced.

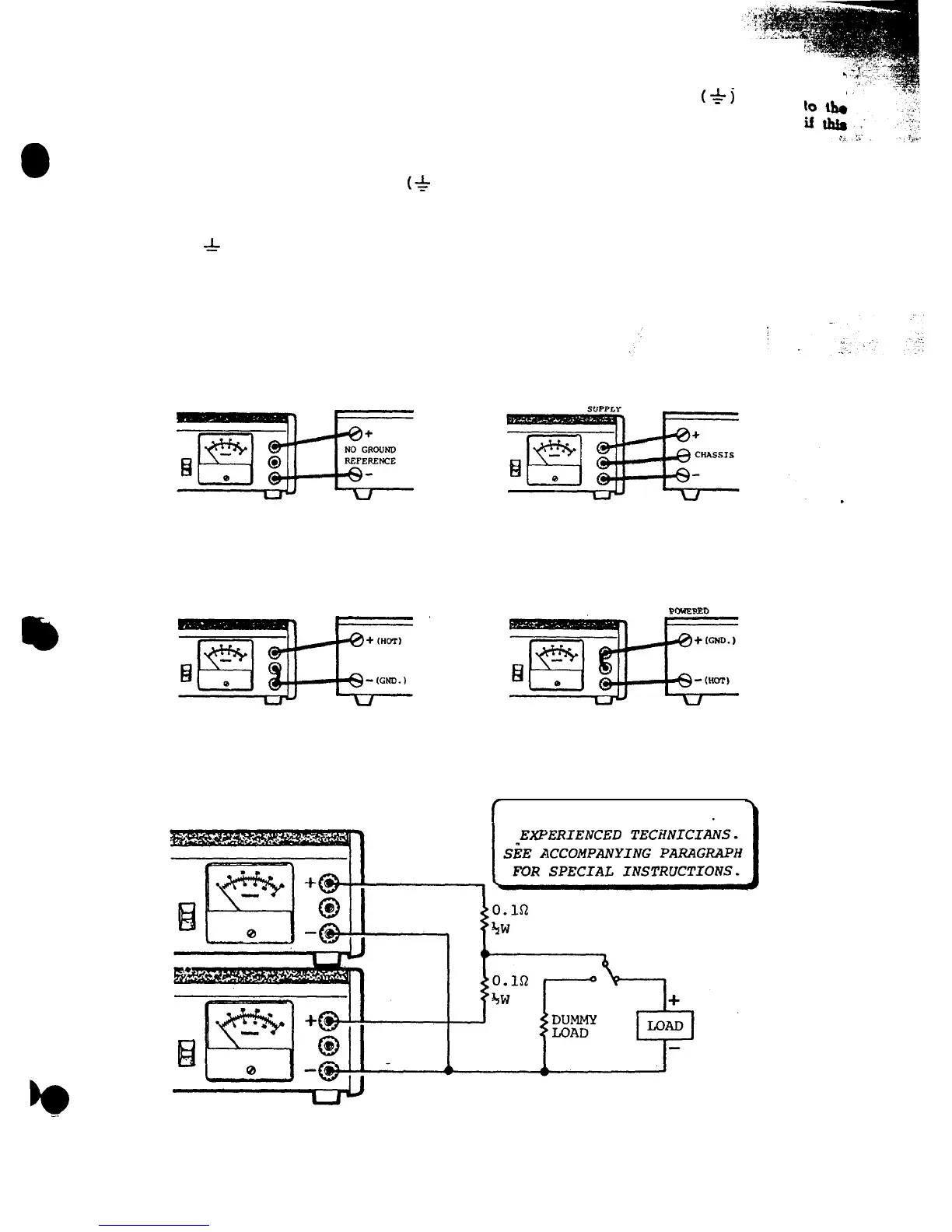

Figure 3 shows the proper interconnection between

the power supply and the equipment under test for

all possible situations.

8

POWER

SUPPLY

EQUIPMENT

BEING

POWERED

EQUPMENT

POWER

BEING

SUPPLY

POWERED

-F'

If there is any doubt that the chassis

may

not

be

common with the negative polarity, use a se-

ground connection from the

(*l

terminal

equipment chassis. No damage can result

technique is used.

Set the power supply voltage to the specification

voltage for the equipment being serviced

(normally

the voltage value of a fully charged vehicle

battery).

Set the current limit to the maximum input

current

specification plus 5%.

If specification information

is unavailable, start with a moderate current

limit

and find the overload threshold. Increase the

cur-

rent limit 5% above threshold to prevent

overload

turn-off during testing.

Note that most solid

state

receivers have a much higher load current

with

strong audio output. Therefore, the threshold

should

EQUIPMENT

POWER

BEING

POWERED

POWER

EQUIPMENT

BEING

SUPPLY

Figure 3. Power Supply Interconnect Possibilities

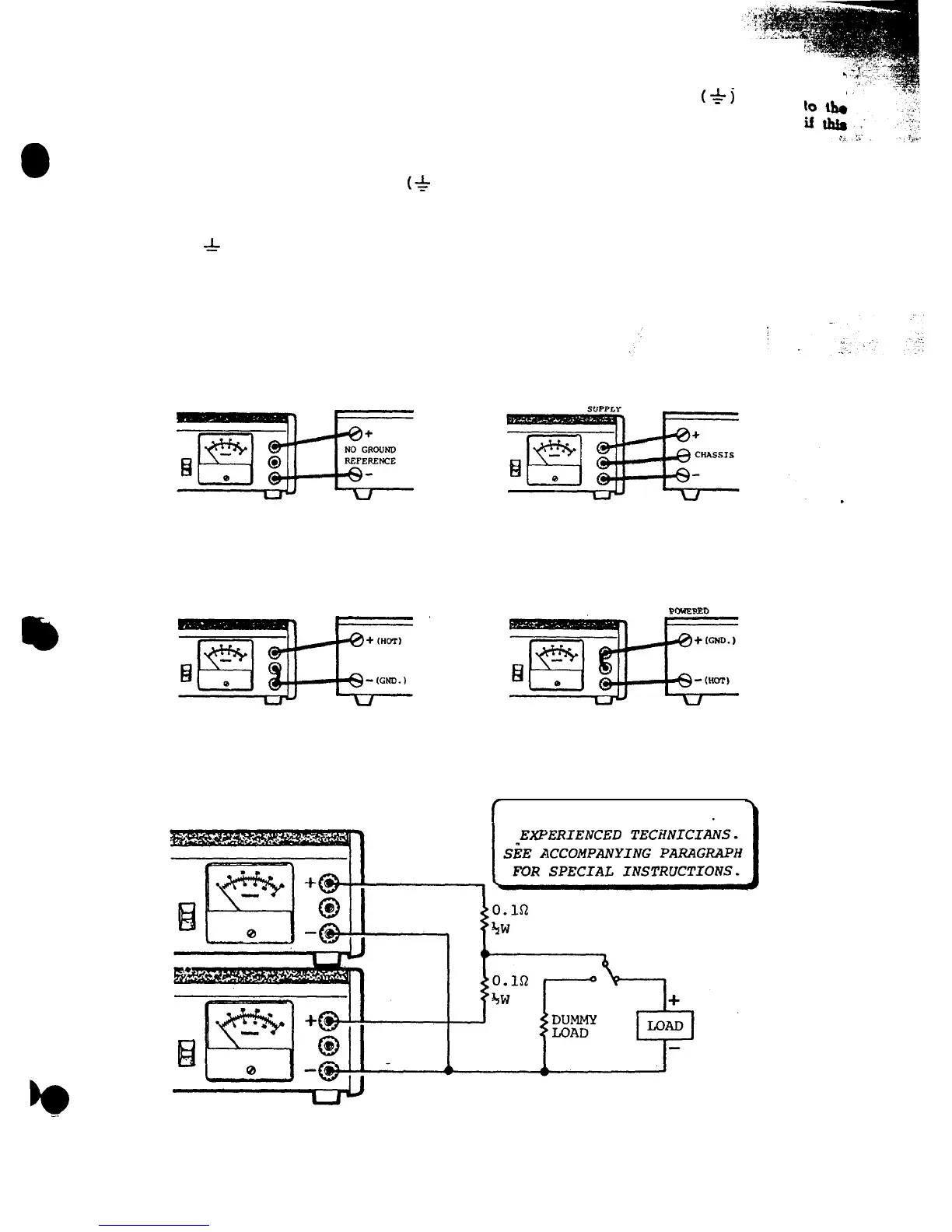

POWER SUPPLY

#l

f

RECOMMENDED ONLY FOR

POWER SUPPLY

#2

Figure 4. TWO Power Supplies Connected in Parallel for 4 Amp Output

Loading...

Loading...