the power supply is not normally used nor required

in this application.

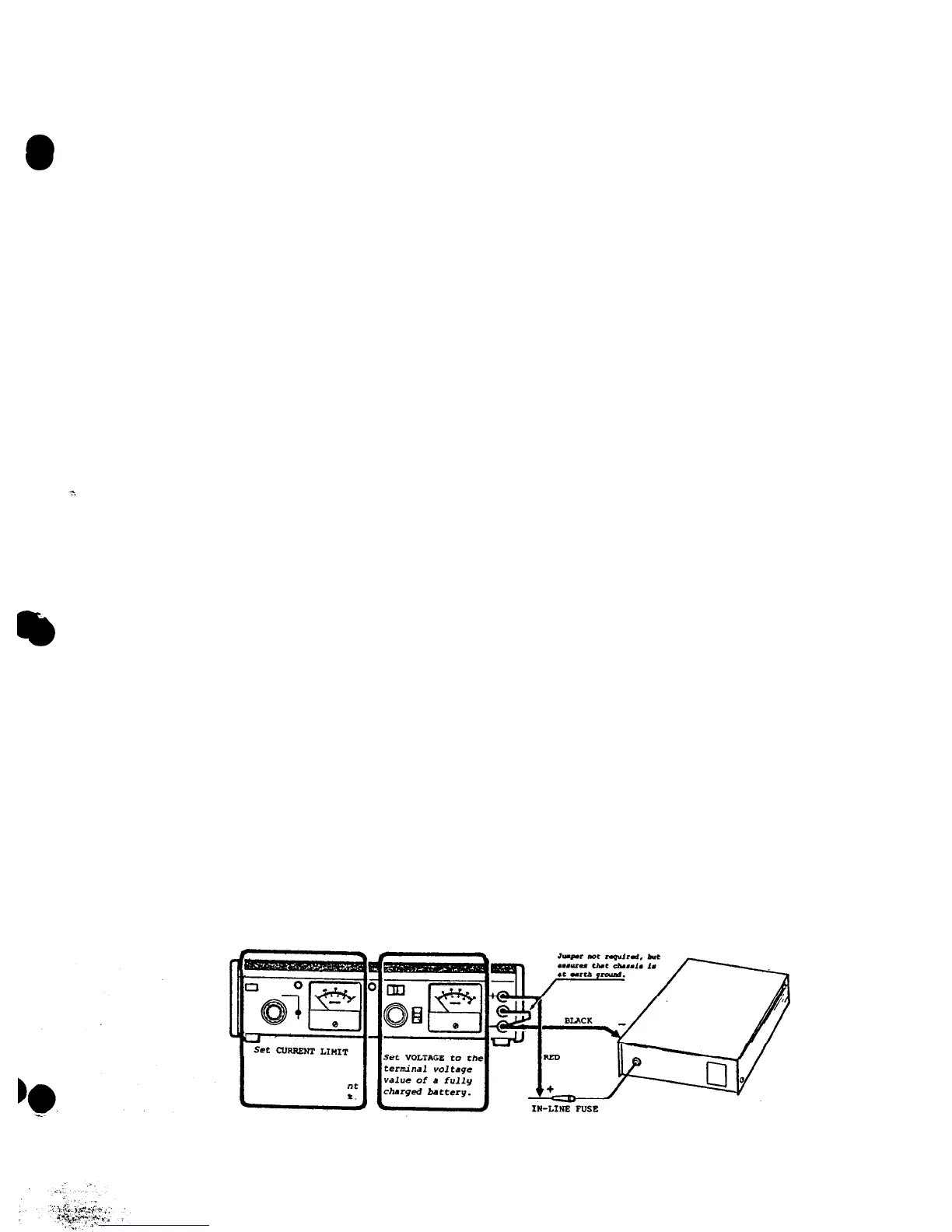

Using separate test lead colors,

such

as red and black, reduces the chance of acci-

dental

reverse polarity connection. Set the current

limit to the maximum input current specification of

the equipment being serviced.

If

this figure is un-

kn

o

wn, start with a low current limit and increase

the setting in small increments until the overload

circuit in the power supply does not trip when power

is applied to the unit under test. Set the voltage to

the same value that would be present if a full set of

fully charged batteries were installed. Flashlight

cells of all sizes are rated at 1.5 volts ‘each. Other

batteries normally state the voltage on the label,

and

the required operating voltage for the equip

ment being serviced is often stated on a label in

the equipment. For units using more than one bat-

tery, check whether the batteries are connected in

series or parallel. For the parallel connected ar-

rangement, set the power supply voltage to that of

a single cell; a higher voltage may damage the

equipment. For the series connected arrangement,

add the voltages of all cells and set the power sup

ply voltage to that sum.

A simplified method of making connections to the

power input points of battery operated equipment

may be to use a “dummy” battery. A dummy bat-

tery sits in the battery compartment and makes

good electrical contacts with the power input points,

but has readily accessible terminals or test leads

for interconnection to the power supply. The body

of the dummy battery may be made from wood or

other nonconductive material. The end caps must

be good electrical conductors which are connected

to terminals or test leads. The unit must fig snugly

in the battery compartment to assure good electrical

contact. An improved version may include a spring

to insure a snug fit.

SERVICING VEHICULAR

ELECTRONICS EQUIPMENT

When servicing electronics equipment for auto.

mobiles. trucks, and other vehicles, the equipment

is normally removed from the vehicle for bench

testing.

This power supply is an excellent dc power

source for bench testing such equipment. The

fol-

lowing items are among the more common types of

vehicular electronics equipment that may be

powered from this power supply:

POWER

SUPPLY

AM, AM/FM and AM/FM/Stereo automobile

receivers

*Tape players

Citizen’s band transceivers

Monitor receivers

Automobile amateur radio receivers

*Some aircraft equipment

*Some ship-to-shore and ship-to-ship marine band

transceivers

*Some vehicular two-way communications trans-

ceivers

*Some automotive amateur radio transceivers

‘Maximum current 2 amperes unless special procedures are

used as described in this section of the

manual.

Most automobiles and other vehicles use

12-volt

electrical systems. Although the electrical system is

normally referred to as a

12-volt

system, actual bat-

tery voltage when fully charged is approximately

14 volts. The power supply may be set

at

14 volts

for servicing equipment from vehicles with

12-volt

electrical systems.

Some trucks use a 24-volt

elec-

trical

system; bench testing of equipment from these

systems should be performed at 28 volts. Aircraft

normally use a 28-volt electrical system, and a

bench test voltaqe of 32 volts is used.

Practically all vehicles use a negative ground

electrical system, althouqh a positive ground system

is occasionally found. Electronic equipment which

is built for use only in negative ground vehicles

usually has its chassis common with the negative

polarity of input power. In some cases, there is no

separate negative polarity power cable, since the

chassis

becomes

grounded

when the equipment is

installed in the vehicle. Some equipment is built for

use in either neqative or positive ground electrical

systems, in which case the chassis may be isolated

from both the positive and ‘negative input polarities.

There is virtually no equipment built for positive

ground electrical systems only, although some elec-

tronics equipment may use its ungrounded positive

polarity as reference for circuit operation.

CAUTION

Carefully observe polarity of connections.

Equipment may be damaged if polarities

are reversed.

When servicing this type of equipment, the

(+)

and

(-)

terminals of the power supply should be

connected to the

(+)

and

(-)

power input points of

the equipment being serviced with test leads.

Fig-

EQUIPMENT

BEING

SERVICED

to

maximum

input

current

specifi-

cation of

eguipme

being

serviced

+5

Figure 2. Typical Power Supply Connections to Vehicular Equipment

(Negative Ground System, Grounded Chassis Shown]

7

Loading...

Loading...