INSTALLATION

588/A page 6/24

COMPRESSOR FLYWHEEL

Blackmer compressors are fitted with flywheels which

MUST be used regardless of the type of drive system

employed.

Hazardous

machinery can

cause serious

r

n

l in

r

.

FAILURE TO DISCONNNECT AND

LOCKOUT ELECTRICAL POWER OR

ENGINE DRIVE BEFORE ATTEMPTING

MAINTENANCE CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH

Flywheels must be properly installed and aligned:

1. Ensure that the mating surface between the hub

and flywheel are clean and dry – do not use a

lubricant.

2. Install the hub and key on clean compressor shaft,

flange end first.

3. Tighten the hub setscrew just enough to prevent it

from sliding on the shaft – do not overtighten.

4. Place the flywheel on the hub and loosely thread

the capscrews with lockwashers into the assembly.

Do not use lubricant on the capscrews.

5. Tighten all capscrews evenly and progressively in

rotation to the torque value in Table 4. There must

be a gap between the hub flange and the flywheel

with installation is complete. DO NOT OVER-

TORQUE. DO NOT ATTEMPT TO CLOSE GAP

BETWEEN HUB FLANGE AND FLYWHEEL.

Hub

Size

Capscrew

Size

Torque

ft-lbs. (Nm)

SF

3/8 – 16 30 (40.7)

E

1/2 - 13 60 (81)

F

9/16 – 12 110 (149)

Table 4 – Flywheel Hub Torque Values

6. Ensure that the radial and axial runout values at the

rim do not exceed the following values:

Radial O.D. Runout: 0.016 in. (0.4046 mm)

Axial Rim Runout: 0.021 in. (0.5334 mm)

7. Ensure that the compressor flywheel guard is

properly installed before operation. The guard must

not contact moving parts.

Hazardous gases

can cause property

damage, personal

in

r

r

th

FLYWHEEL GUARD CONTACT WITH

MOVING PARTS MAY BE A SOURCE

OF IGNITION IN EXPLOSIVE

ATMOSPHERES CAUSING SEVERE

PERSONAL INJURY OR DEATH

V-BELT DRIVES

Most Blackmer compressors are driven via V-belts

which must be properly aligned and tensioned.

Hazardous

machinery can

cause serious

r

n

l in

r

.

FAILURE TO DISCONNNECT AND

LOCKOUT ELECTRICAL POWER OR

ENGINE DRIVE BEFORE ATTEMPTING

MAINTENANCE CAN CAUSE SEVERE

PERSONAL INJURY OR DEATH

1. Lay a straight edge along the face of the motor

sheave and compressor flywheel.

2. Adjust either as needed to provide alignment.

3. Tighten the V-belts such that they are taut, but not

overly tight. Moderate thumb pressure should

deflect each belt about 1/4 – 3/8 in. (6 – 10 mm).

Consult your V-belt supplier for specific values.

4. Check the belt tension after 24 - 48 hours run-in.

Recheck the tension periodically, and tighten the

belts as required.

Caution should be used to avoid overtightening belts,

which can shorten bearing and belt life. Belts should

be inspected periodically for signs of excessive wear

and replaced if necessary.

Hazardous

machinery can

cause serious

r

n

l in

r

.

OPERATION WITHOUT GUARDS IN

PLACE CAN CAUSE SERIOUS

PERSONAL INJURY, MAJOR

PROPERTY DAMAGE OR DEATH.

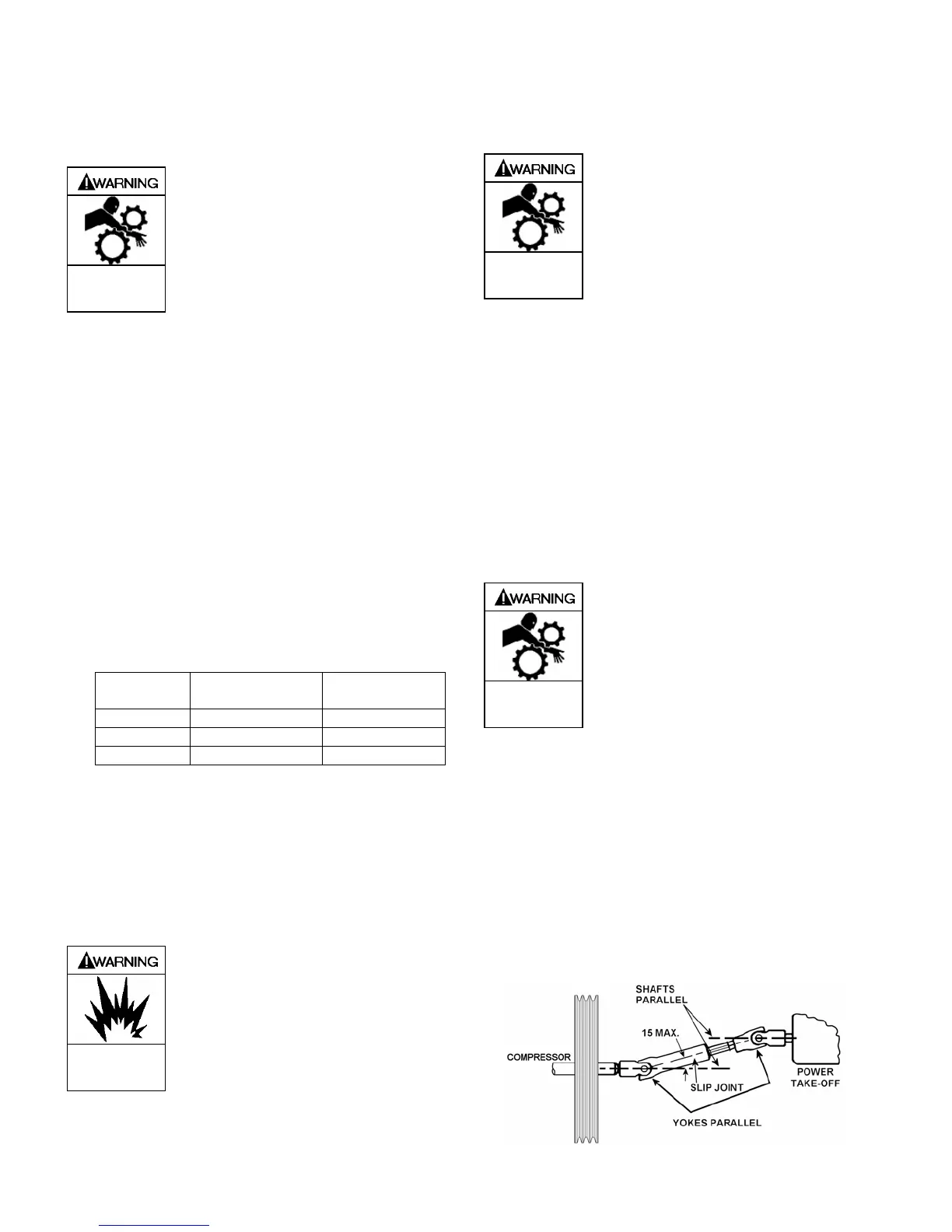

PTO DRIVES

Truck mounted Compressors may be driven by the

power take-off through a jackshaft connected by

universal joints. The compressor must be fitted with an

optional extended crankshaft to use a PTO drive without

removing the flywheel. Proper PTO installation is

essential:

1. Compressor shaft and PTO shaft must be parallel.

2. The yokes at the end of the jackshaft must be

parallel and in phase.

3. The angle between two shafts must not exceed 15°.

4. An EVEN number of U-joints must be used.

Loading...

Loading...