15

General Maintenance Points

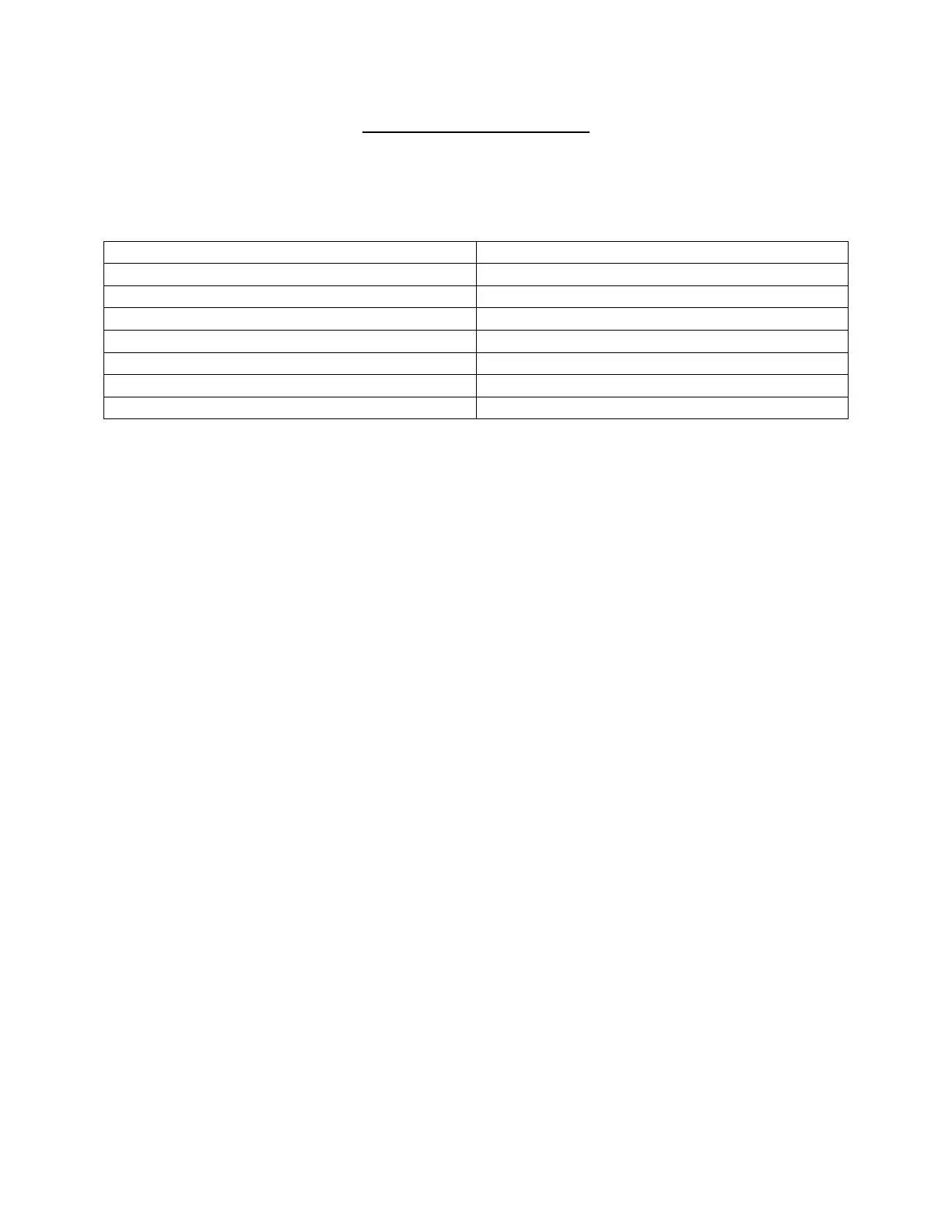

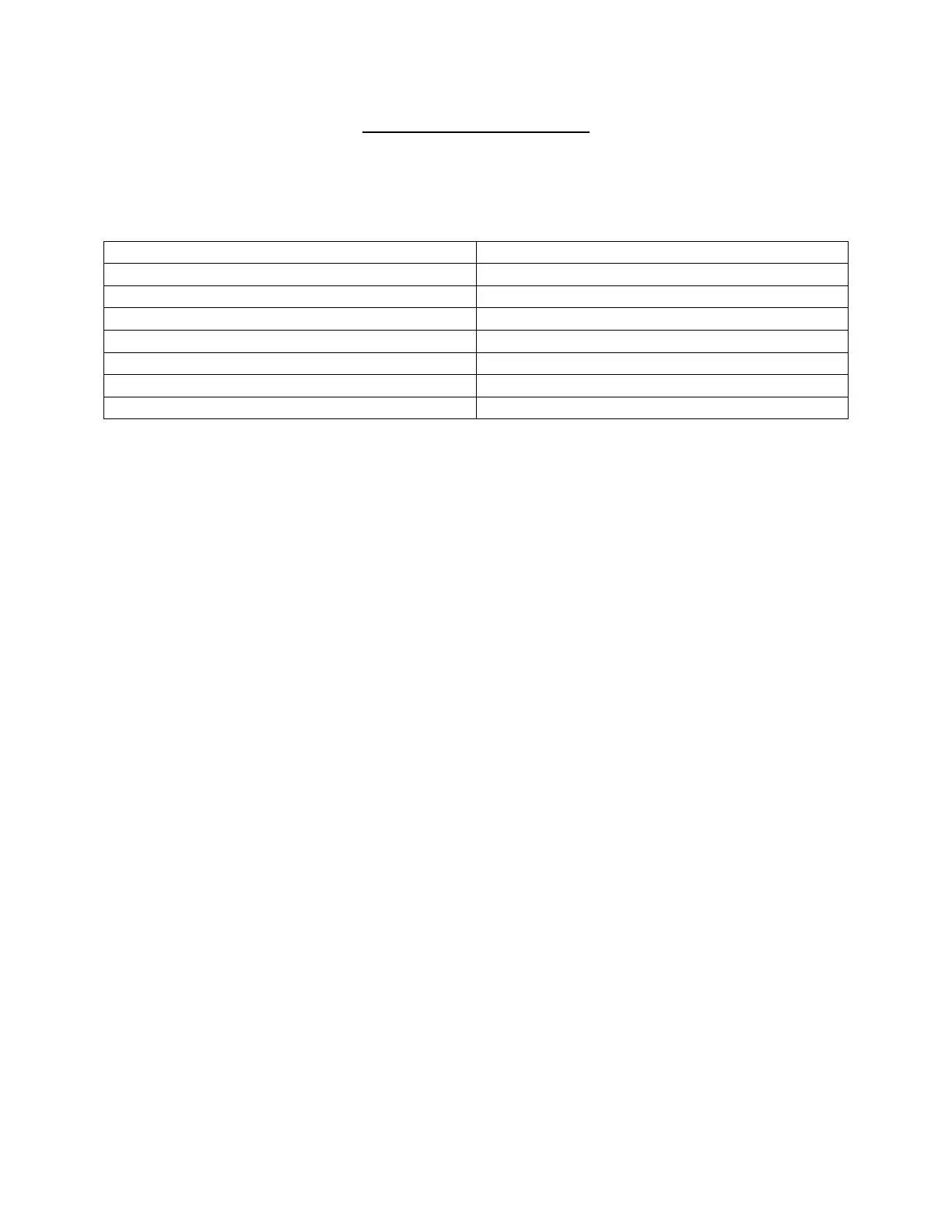

Below is a matrix of general maintenance points and intervals. These intervals are general

recommendations based on normal operation. These intervals should be adjusted during use in

extreme conditions or extended periods of used.

MAINTENANCE POINT INTERVAL

INSPECT SEALS DAILY

INPECT LINERS DAILY

INSPECT WHEEL KIT DAILY

INSPECT POWER CHORD DAILY

INSPECT DUST HOSE DAILY

CHECK/ADJUST BELT TENSION EVERY 4-6 HOURS

GREASE BEARING UNIT EVERY 50 HOURS

Greasing the Bearing Unit

The bearing unit is located on the back of the blast housing. The unit must receive regular

lubrication to operate properly. Blastpro Manufacturing recommends using Mobil Polyrex EM

grease.

There are grease fittings at both ends of the bearing unit. Each fitting should receive several

pumps of grease. Once the unit is greased, run the unit without blasting for 10-15 minutes. This

will help distribute the grease evenly. Care should be taken not to over-grease the unit.

Checking Belt Tension

Correct blast wheel belt tension is required to maximize efficiency and prolong the life of the

belts, bearing unit and sheaves. If the belt does not have enough tension there will not be proper

power transmission from the motor to the blast wheel. An overly tight, or loose, condition can

lead to accelerated belt wear.

When checking the belt tension, the belt should deflect 1/64” per inch of center-to-center

distance between the sheaves. The optimal force for testing the belt is 11 lbs (min 9, max 13).

When possible, the use of a belt tension tester is recommended.

Loading...

Loading...