3

Introduction

The BP-10 SUPER operates on dual voltage, 230/460 volts, 208 3-phase, and offers a 10” blast

pattern. The newly designed blast wheel and the advanced air wash system, along with the high

quality control box and electrical components that are engineered and constructed by a UL

certified electrical contractor result in longer lasting wear parts. The BP-10 SUPER is sold with

the BP-9-54 dust collector to keep work areas clean and dust-free. The BP-10 SUPER’s

versatility makes it suitable for use on medium to large projects, including warehouse floors,

parking garages, industrial plants, bridges, and highways. The BP-10 SUPER has a travel speed

of 0-100 feet per minute and production capacity from 300-1550 square feet per hour. Shot size:

S-280 to S-460. Wear parts are interchangeable with BLASTRAC

®

parts.

The mechanics of the BP-10 SUPER are fairly simple. When the shot lever is opened, a cable

connected to the shot lever opens the shot valve which subsequently allows shot from the shot

hopper to be released. The shot then moves through the shot valve, down the feed spout, and

into the blast wheel which sits in a control cage. Simultaneously, a 15 horsepower 3-phase

motor is spinning the blast wheel at a very high rate of speed. This spinning blast wheel then

acts to throw the shot through an opening in the control cage and down onto to the concrete

surface that is being cleaned. Due to the high rate of speed at which the shot is traveling, it

fractures the underlying concrete surface which consequently produces concrete dust. After

hitting the concrete surface, the shot rebounds off of the surface and, through a combination of

the rebound effect and the use of a vacuum, the shot and the concrete dust then move through the

blast housing. Because shot is heavier than concrete dust, gravitational force separates the shot

and the concrete dust. The shot is then sent back into the shot hopper where it is continuously

recycled by the machine. As for the concrete dust, it is sucked into a duct hose which travels

from the blast housing to the dust collector. After traveling through the duct hose, the concrete

dust is deposited in the dust collector’s dust bin.

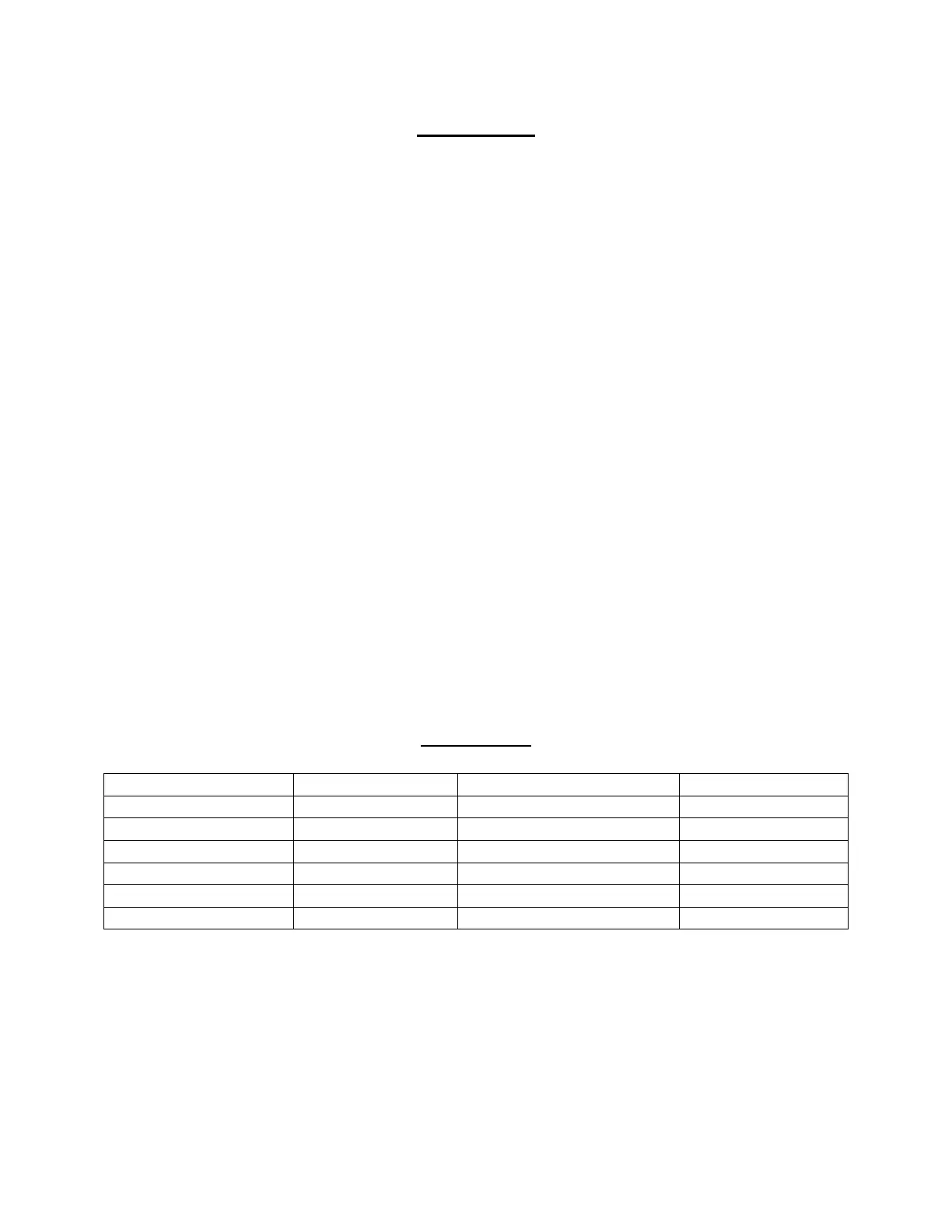

Specifications

Model Number:

BP-10 SUPER

Minimum Generator:

40 kW

Production Capacity:

1,550 sq. ft./hr.

Dimensions (L x W x H):

63” x 17” x 40”

Blast Pattern:

10”

Weight:

736 lbs.

Travel Speed:

0-90 ft/min.

Power Cord Included:

55 ft.

Blast Motor:

15 hp

Seals:

Magnetic

Voltage:

230 / 460 V, 60 Hz

Distance to Edge:

2.5”

Amperage:

49 / 23.5 Amp

Dust Collector:

BP 9-54

Loading...

Loading...