25

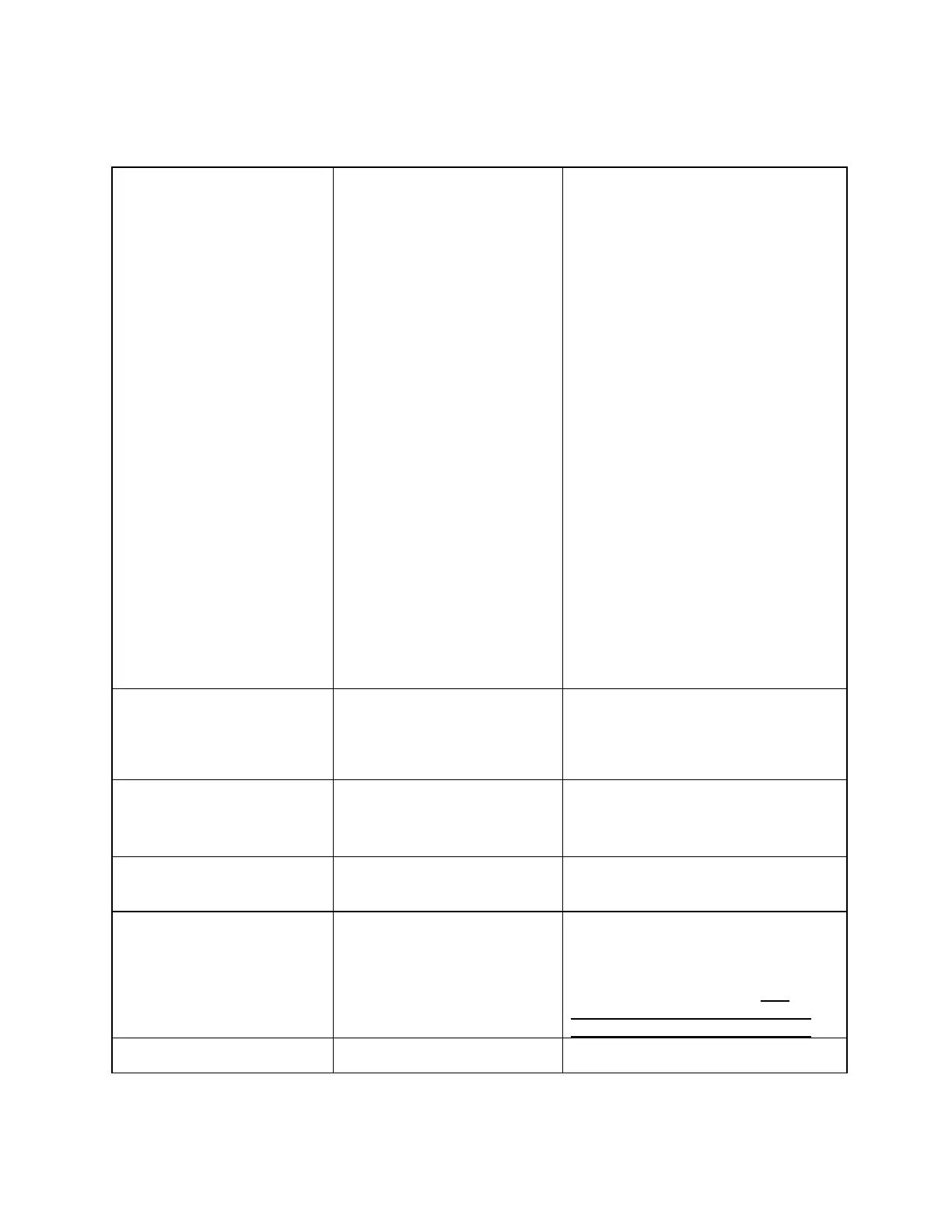

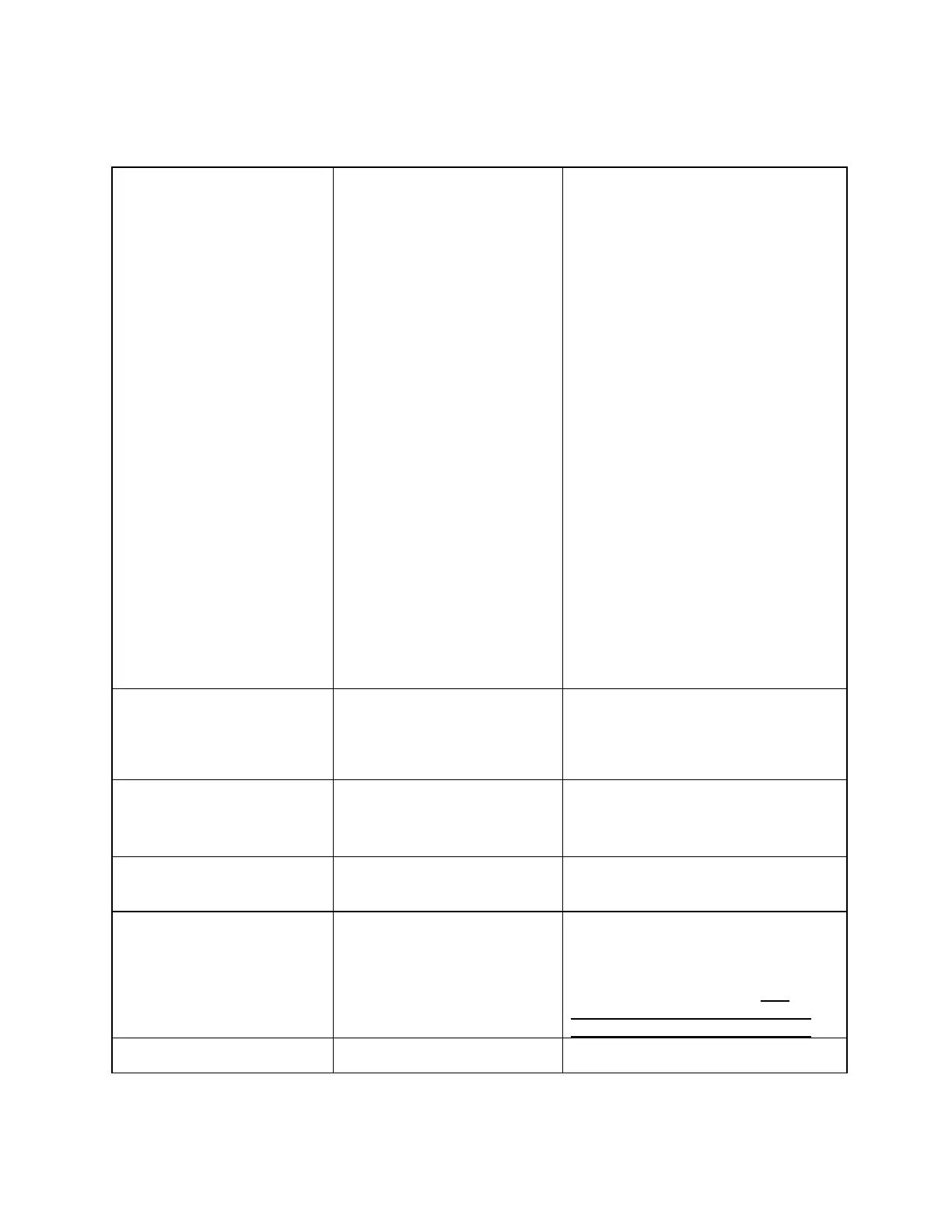

Troubleshooting

Increased cleaning time. Improper abrasive feed to

wheel.

Storage hopper.

Contaminated abrasive.

Abrasive feed and abrasive

control valve.

Wheel impeller, control cage

wear.

Drive belt.

Loss of consistent blast

pattern, “hot spot”.

Choked wheel.

Check ammeter reading. Low reading

indicates insufficient abrasive getting

to wheel.

Check abrasive level.

Abrasive may contain substantial

percentage of fines and contaminants.

Check ventilation.

Check for obstructions in the abrasive

feed, i.e. feed spout, abrasive control

valve, separator screen.

Replace wheel kit.

Check belt for proper tension,

alignment or wear.

Check blast pattern. Check the blast

wheel for proper seating with the

wheel hub.

Close abrasive valve and gradually

reopen. Check abrasive valve

operation, check “over-amping” blast

wheel.

Excessive wear on blast

housing rebound chamber /

liners.

Improper setting of control

cage.

Abrasive is being misdirected into

internal components instead of work

area. Check blast pattern and

readjust.

Abrasive leakage. Improper sealing.

Improper control cage setting.

Check all seals for wear.

Abrasive rebounding from side of

machine. Check blast pattern.

Machine will not drive. Drive pin not installed

Install drive pin.

Machine hang-up. Uneven work surface / floor

obstruction.

Push down on steering handle to raise

machine to clear small obstructions or

uneven work surfaces. Shut abrasive

valve if obstruction can be cleared.

Reverse direction to clear. Use

caution when raising seal due to

high velocity abrasive exposure.

Loss of cleaning action. Machine travel speed too fast. Adjust travel speed.

Loading...

Loading...