11

Boy

Fig.2

Dear customer,

Congratulations on purchasing an Steinweg-Böcker-

Baumaschinen GmbH hoist, a reliable and innovative product

created through years of experience.

-

WORKING IN SAFETY: The following instructions

are essential for safety.

This OPERATING AND MAINTENANCE manual must be kept on

site by the foreman and must be accessible for consultation at

all times.

The manual is be considered an integral part of the machine

and must be kept for future reference (EN ISO 12100-2) until

the machine is scrapped. If it is damaged or lost, a replacement

copy can be requested from the hoist manufacturer.

The manual contains important information on site preparation,

installation, operation, maintenance and ordering of spare parts.

The installer and operator must have adequate experience and

knowledge of the machine.

To guarantee complete safety of the operator, safe operation

and a long service life, follow the instructions in this manual

and observe current applicable legislation regarding safety and

accident prevention in the workplace (use of suitable footwear,

clothing, hard hats and safety harnesses, proper installation of

railings around drops, etc.).

-

It is strictly forbidden to modify the steel structure

or working parts of the machine in any way.

Steinweg-Böcker-Baumaschinen GmbH will accept no

responsibility for failure to comply with legislation and standards

governing the use of hoisting equipment, in particular: improper

use, incorrect power supply, inadequate maintenance,

unauthorised modifications, tampering and/or damage and partial

or complete failure to observe the instructions contained in this

manual.

-

Steinweg-Böcker-Baumaschinen GmbH reserves

the right to modify the characteristics of the hoist and/

or the contents of this manual without any obligation to

update previous machines or manuals.

1. GENERAL DESCRIPTION

-

Warning: Use of lifting equipment requires great

skill and care. The hoist must be used by skilled and

properly instructed personnel only.

-

1) The machine is designed exclusively for lifting

materials and for use on building sites.

-

2) The machine must not be used for lifting people

and/or animals.

-

3) The machine must not be used in potentially

explosive atmospheres or underground.

The machine consists essentially of (fig. 1):

- Drum type winch fitted to reduction gear shaft (3), wire rope

(1), lift hook (2) and counterweight (10).

- Gearmotor consisting of a self-braking electric motor (4) and

an oil-bath reduction gear unit (14).

- Electrical system (5).

- UP position control lever (9).

- DOWN position control lever (17).

- Rotary frame (7) with telescopic arm (6), loocking handle (8) and

frame locking lever (11).

- Thermal overload (16) which stops the winch when the current

exceeds the nominal value (press to reset).

- The winch has three types of pendant control (15)

1.5 m lead direct pendant

30 m low voltage (24V) pendant.

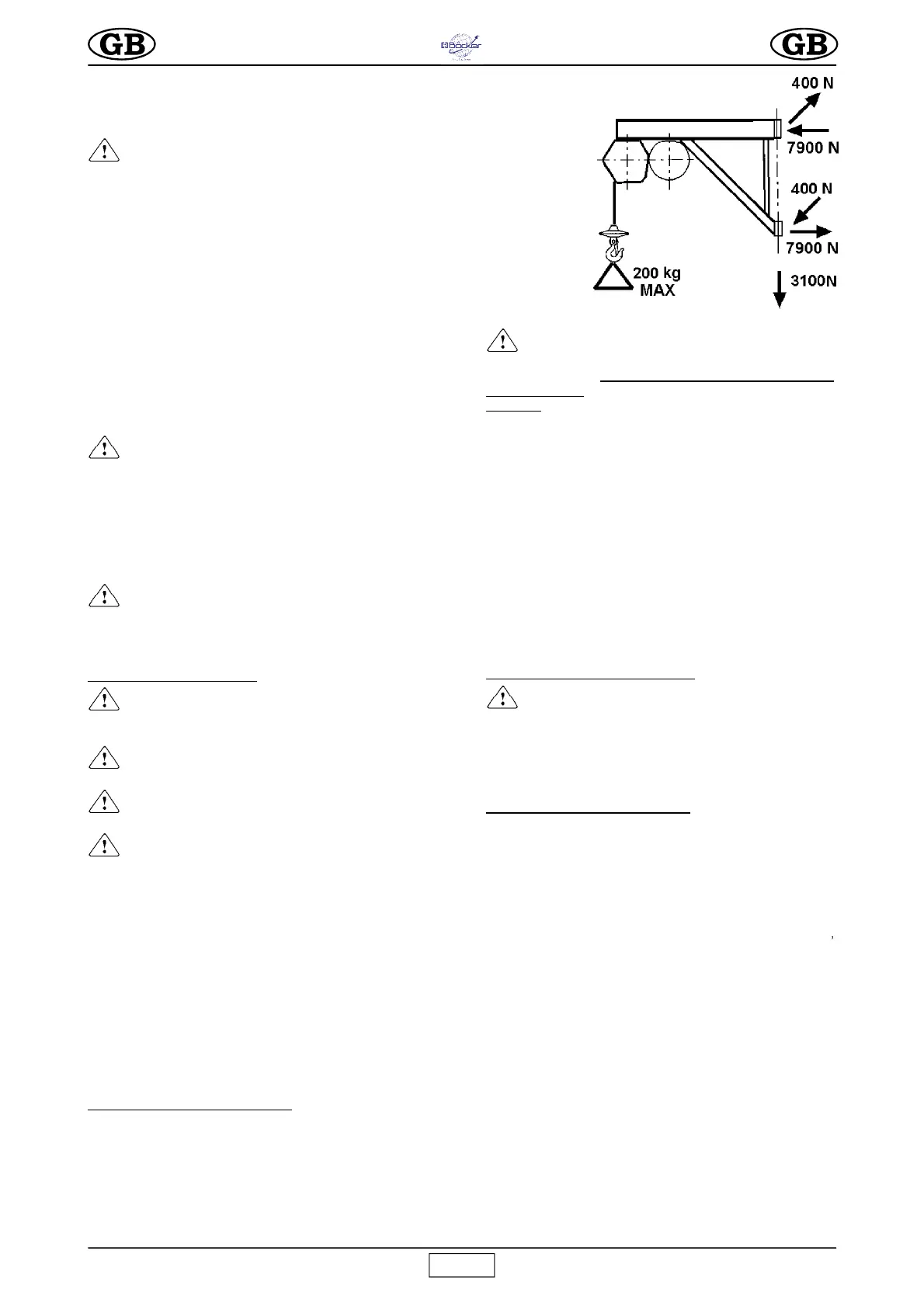

2. HOIST SUPPORT STRUCTURE

The structure on which the hoist is mounted must be able to

withstand the stresses generated during operation (fig. 2).

The 400 N force is perpendicular to the 5000 N force. Since the

hoist is able to rotate on the supporting hinges, these forces

must be verified in all possible positions of the hoist.

Steinweg-Böcker-Baumaschinen GmbH offers a wide range of

supports (see figures 7, 8, 9, 10, 11) for use on building sites, designed

to suitably transfer the stresses to the building structures.

-

IMPORTANT

The EC declaration of conformity enclosed with this

manual is valid only if components manufactured

exclusively by Steinweg-Böcker-Baumaschinen GmbH

are used

(hoist and support structures).

If this condition is not satisfied, this declaration is valid

only for the hoist.

The installer should compile a new EC declaration of

conformity, after verifying all requirements stated in

the Machinery Directive 2006/42/EC for the equipment

and support assembly.

The forces on the support couplings must be accounted for in

calculations for the supporting structures (scaffolding,

balconies, ceilings, etc.) made by a qualified technician.

If the hoist is to be mounted on scaffolding, the latter must be

adequately braced against wind (see fig. 12).

Follow the instructions provided for installation of the various

supports.

If supports with different capacities from the hoist are used,

the permissible capacity of the weakest element in the system

must be marked on the assembly in a clearly visible position.

2.1 PREPARING THE WORKPLACE

- The loading access area must be protected by a

rail at least 1 m high and with a foot stop.

- Make sure that the lifting run is free from obstacles and make

sure that no one can lean out from intermediate floors.

- Cordon off the ground loading area to ensure that no one

enters the area during lifting.

3. MOUNTING THE HOIST (fig. 1)

1) Only competent, trained personnel may assemble and ope-

rate the hoist.

Given the weight of the hoist, it must be transported and

installed by an adequate number of operators to avoid

hazardous situations.

2) The maximum working height (30 m) corresponds to the

gearmotor position, i.e. it is measured from the top hinge of the

support.

3)

Secure the support to the building and check the support pins

vertical alignment (12); then lift the locking lever (11) to insert the

frame bushings (7) onto the pins and fit the split pin retainer (13).

4) Fit the telescopic arm (6) to the frame (7) at its minimum extension,

screw on the locking handle and washer in the threaded hole through

its slot and tighten fully.

5) Ensure that the hoist is completely level by means of a spirit

level placed on the top plate of the drum. (fig. 1).

6)

The telescopic arm (6) allows a lifting excursion from the

axis of the pins of between 720 and 1120 mm.

7) When assembling on a trestle support, fit the telescopic arm (6) to

the carriage through the securing holes (fig. 12) using bolts and

locknuts. For the rest, follow the instructions for the trestle support.

5)

Insert the direct pendant control (1.5 or 5 m lead) plug in the

electrical panel (5)

and hook the spring clip of the steel cable

onto the ring on the electric panel to avoid pull on the electric

cable.

For the 24V low voltage pendant fix the electrical panel on the frame

(7) and insert the connector in the panel (5).

All pendant controls have 3 pushbuttons (Fig. 3):

O

R

I

G

I

N

A

L

T

E

X

T

Loading...

Loading...