14

Boy

-

Check the gearmotor oil level through the sight

glass before every start-up. Refill as required. The oil

should be changed approximately every 2000 hours. Use

gear oil with ISO VG 460 viscosity at 40°C

(SAE 90-140)

.

-

Spent oil is classed as special waste and must be

disposed of in accordance with current applicable

legislation.

7.4 ELECTRICAL SYSTEM

Check the condition of the insulating pendant control case. If it

is damaged replace it with an original

STEINWEG

spare. Make

sure that the steel cable connecting the pendant control to the

electrical panel is shorter than the electrical cable to protect

against pulling.

8. DISMANTLING THE HOIST

Remove all loads from the hook.

Wind the wire rope completely onto the drum. Disconnect the

power plug.

Remove the split pin from the support hinge and remove the

rotating frame.

If a trestle is being used, the carriage must be removed from the

hoist after it has been taken off the guides and before the

counterweight is removed.

9. TRANSPORT AND STORAGE

- Do not leave the installed hoist unattended without first

disconnecting the electric power supply and winding the rope

completely onto the drum.

When the machine is to be stored for a long period of time, make

sure that it is protected against atmospheric agents.

- During transport protect the machine from shock and crushing

which can adversely affect its functionality and mechanical

strength.

10. SCRAPPING THE HOIST

To scrap the machine at the end of its service life, carry out the

following steps:

a) Drain out the oil by removing the oil plug.

b) Separate the various plastic and electrical components

(cables, pendant control, etc.).

c) Divide up the metal components according to the type of

metal (steel, aluminium, etc.).

After the various components have been separated, dispose

of them through authorised disposal centres.

-

Dispose of properly. These components can cause

accidents and pollution.

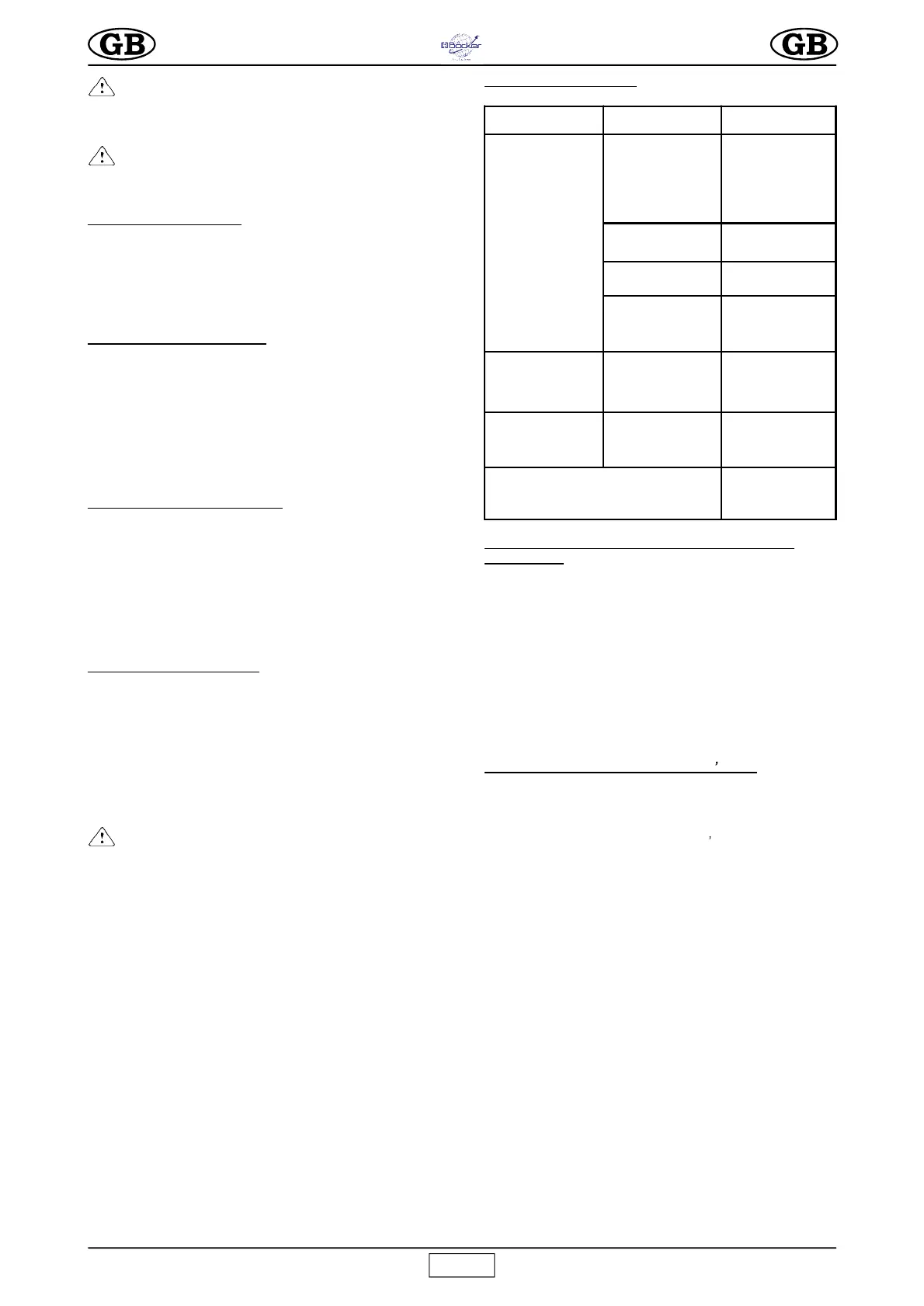

FAULT CAUSE SOLUTION

The machine

does not lift or

lower on

command

Emergency stop

button engaged

Turn to

disengage

No power to

machine

Check mains

cable

Plug not inserted Insert the plug

Power board

cutout tripped

Reset the

overload trip

Difficult to

lengthen the

telescopic arm

Lock knob too

tight.

Slacken.

The machine

lowers but does

not lift.

Up limit switch is

faulty.

Repair.

IF THE FAULT PERSISTS Contact

STEINWEG

Technical Service

11. TROUBLESHOOTING

12. PROCEDURE IN EVENT OF FAULT WITH LOAD

SUSPENDED

- If possible remove the load from the nearest level, then

dismantle and service the hoist.

- If this is not possible, use another lifting machine (with adequate

lifting capacity) from higher up and suspend the faulty hoist

both at the load and at the hoist attachment point.

Lift the faulty hoist slowly off its fitting, then lower the entire

assembly to the ground.

- Do not attempt to turn the brake adjustment nut, as it would

become uncontrollable.

- Do not attempt to repair the fault on the machine with the load

suspended.

13. NOISE LEVEL AT THE OPERATOR

S EAR

The level Lp(A) given in the TECHNICAL DATA chart

corresponds to the weighted equivalent sound pressure level

on scale A of European Directive 2000/14/EC. This level is

measured with no load, at the operator

s head in the working

position 1.5 metres away from the instrument, considering the

different working conditions.

Loading...

Loading...