1 689 979 086 2018-06-08| Robert Bosch GmbH

Maintenance | EFEP 60H / EFEP 67D | 19

en

5. Maintenance

5.1 Maintenance

The filter insert in the oil tank must be replaced

regularly. After adding new test oil, the interior of the

EFEP 60H/67D must be rinsed by operating the lever.

When doing so spray into the extractor device without

the nozzle and holder assembly.

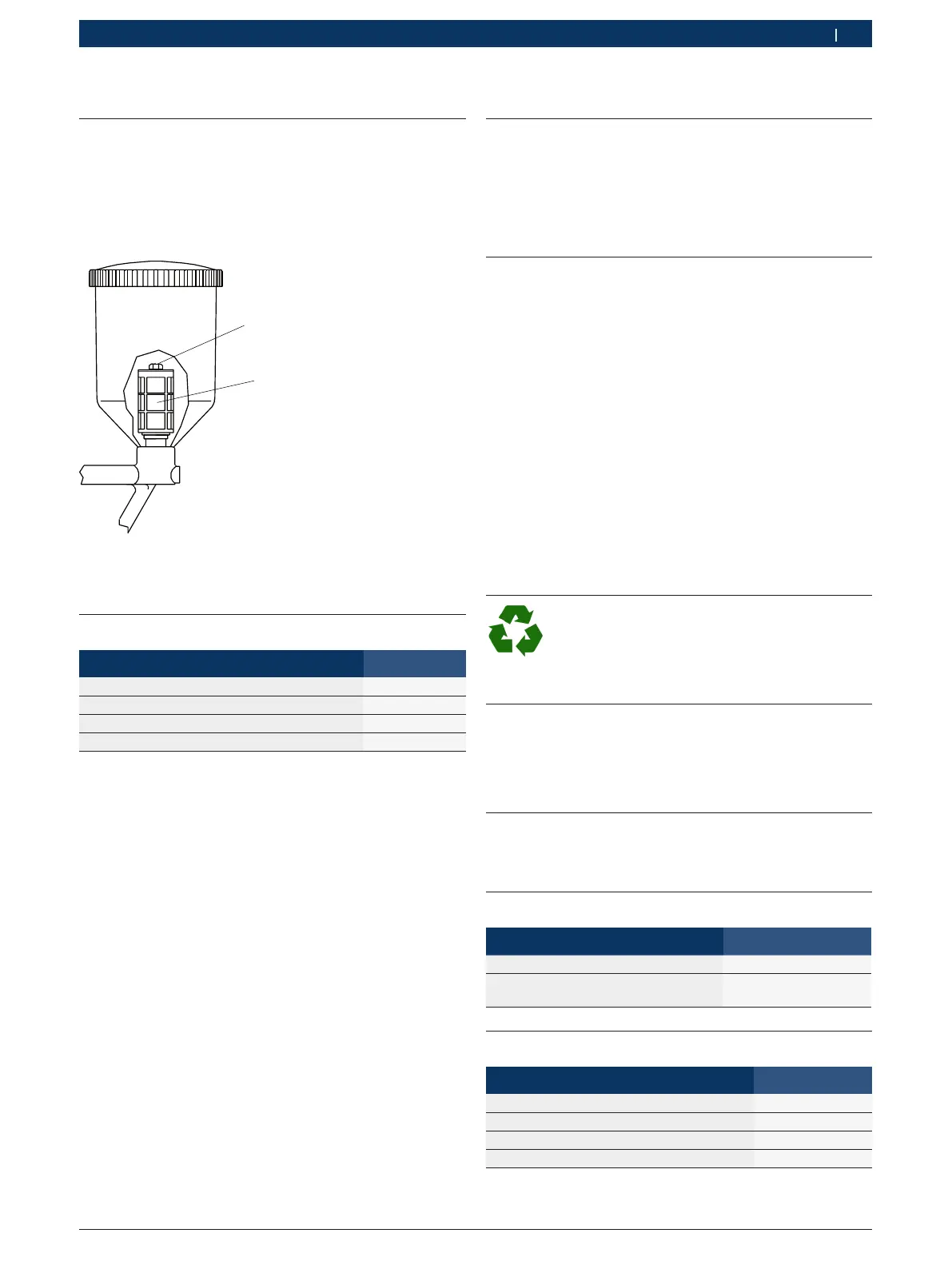

1

458759-3

Fig. 3: Replacing the filter insert

1 Hexagon bolt

2 Filter insert

5.2 Spare and wearing parts

Description Order Number

Oil tank (plastic) 1 685 400 014

Filter insert

<)

1 687 431 011

Shutoff valve with valve spindle for EFEP 60H 1 687 415 047

Shutoff valve with valve spindle for EFEP 67D 1 687 415 048

<)

Wearing parts

6. Decommissioning

6.1 Change of location

¶ If the EFEP 60H / EFEP 67D is passed on, all the

documentation included in the scope of delivery must

be handed over together with the unit.

¶ The EFEP 60H / EFEP 67D is only ever to be

transported in the original or equivalent packaging.

6.2 Disposal and scrapping

¶ Dismantle the EFEP 60H / EFEP 67D and sort out

and dispose of the different materials in accordance

with the applicable regulations.

6.2.1 EFEP 60H / EFEP 67D and accessories

6.2.2 Substances hazardous to water

! Oils and greases as well as refuse containing oil and

grease (e.g. filters) represent a hazard to water.

1. Substances hazardous to water must not be allowed

to enter the sewage system.

2. Substances hazardous to water must be disposed of

in accordance with the applicable regulations.

EFEP 60H / EFEP 67D, accessories

and packaging should be sorted for

environmental-friendly recycling.

¶ Do not dispose EFEP 60H / EFEP 67D into

household waste.

7. Technical data

7.1 Pressure gauge

For grade and diameter see overview on last but one

page.

7.2 Test oil tank

Description Value

Test oil tank filling quantity: 600 ml

Filter in test oil tank with precision in

line with ISO 4020-2

330 000 (approx. 15 µ)

7.3 Tightening torques

Description Value

Test pressure line for EFEP 60H/67D 15 +10 Nm

Test pressure line to nozzle holder 15 +10 Nm

Reduction fitting on nozzle holder 15 +10 Nm

Adapter to nozzle holder 15 +10 Nm

Loading...

Loading...