English | 35

Bosch Power Tools 1 609 929 X57 | (12/5/11)

– Additionally, a dust extraction system can be connected

with the Y-adapter (accessory) to vacuum connection 6, to

increase the extraction performance.

The vacuum cleaner must be suitable for the material being

worked.

When vacuuming dry dust that is especially detrimental to

health or carcinogenic, use a special vacuum cleaner.

Changing the Saw Blade (see figures l1– l4)

f Before any work on the machine itself, pull the mains

plug.

f When mounting the saw blade, wear protective gloves.

Danger of injury when touching the saw blade.

Use only saw blades whose maximum permitted speed is

higher than the no-load speed of the power tool.

Use only saw blades that correspond with the characteristic

data given in these operation instructions and that are tested

and marked in accordance with EN 847-1.

Use only saw blades recommended by the tool manufacturer,

and suitable for sawing the materials to be cut.

Removing the Saw Blade

– Using a screwdriver, raise the insert plate 31 at the front

and remove it from the tool basin.

– Turn crank 20 clockwise to the stop, so that the saw blade

32 is in the highest possible position above the saw table.

– Tilt the protection guard 5.x toward the rear to the stop.

– Turn the clamping nut 56 with the ring spanner 15

(24 mm) and at the same time, pull the spindle lock lever

57 until it engages.

– Keep the spindle lock lever pulled and unscrew the clamp-

ing nut turning in anticlockwise direction.

– Remove the clamping flange 58.

– Remove the saw blade 32.

Mounting the Saw Blade

If required, clean all parts to be mounted prior to assembly.

– Place the new saw blade onto the supporting flange 59 of

the tool spindle 60.

Note: Do not use saw blades that are too small. The clearance

between saw blade and riving knife must not exceed 5 mm

(max.).

f When mounting the saw blade, pay attention that the

cutting direction of the teeth (arrow direction on the

saw blade) corresponds with the direction of the arrow

on the blade guard!

– Mount the clamping flange 58 and the clamping nut 56.

– Turn the clamping nut 56 with the ring spanner 15

(24 mm) and at the same time, pull the spindle lock lever

57 until it engages.

– Tighten the clamping nut in clockwise direction. (Tighten-

ing torque approx. 15–23 Nm)

– Reinsert the insert plate 31.

– Tilt protection guard 5.x down again.

Operation

f Before any work on the machine itself, pull the mains

plug.

Transport and Working Position of the Saw Blade

Transport Position

– Turn the handwheel 19 in anticlockwise direction until the

teeth of the saw blade 32 are positioned below the saw ta-

ble 17.

For additional information on transport, see page 39.

Working Position

– Turn the crank 20 clockwise, until the teeth of the saw

blade 32 are positioned above the workpiece.

Note: Take care that the blade guard is properly positioned.

When sawing, it must always face against the workpiece.

Increasing the Size of the Saw Table

Long workpieces must be underlaid or supported at their free

end.

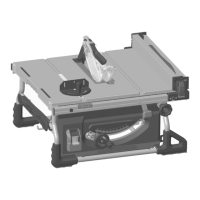

Table Width Enlargement (see figure A)

The table width enlargement 11 enlarges the saw table 17 to-

ward the right by 435 mm (max.).

– Completely pull the clamping handle 18 for the table width

enlargement upward.

– Pull out the table width enlargement 11 to the desired

length (also see “Adjusting the Parallel Guide With the Saw

Table Extended”, page 36).

– Press clamping handle 18 downward.

The table width enlargement is now locked.

Table Extension (see figure B)

The table extension 10 extends saw table 17 to the rear by

520 mm (max.).

– Loosen the locking screws 38 on the guide rods 24.

– Pull out the table extension 10 to the desired length.

– To lock the position, firmly tighten both locking screws 38.

For heavy workpieces, it may be required to support the table

extension.

Sliding Table (see figure C)

With the sliding table 2, workpieces to a maximum width of

350 mm can be sawn.

At the same time, a higher precision is achieved during saw-

ing, especially in conjunction with the angle stop 3. (see

“Sawing Mitre Angles with the Sliding Table”, page 37)

– Completely pull the clamping lever 29 for the sliding table

upward.

In this manner, the sliding table can be moved both toward

the front as well as toward the rear to the stop.

Adjusting the Cutting Angle

To ensure precise cuts, the basic adjustment of the machine

must be checked and adjusted as necessary after intensive

use (see “Checking and Adjusting the Basic Adjustment”,

page 38).

OBJ_BUCH-1375-001.book Page 35 Thursday, May 12, 2011 2:22 PM

Loading...

Loading...