| 13

Installation Instructions

Bosch 18 SEER2 Series Inverter Ducted Packaged Heat Pump - BTC 761703104 A (11.2022)

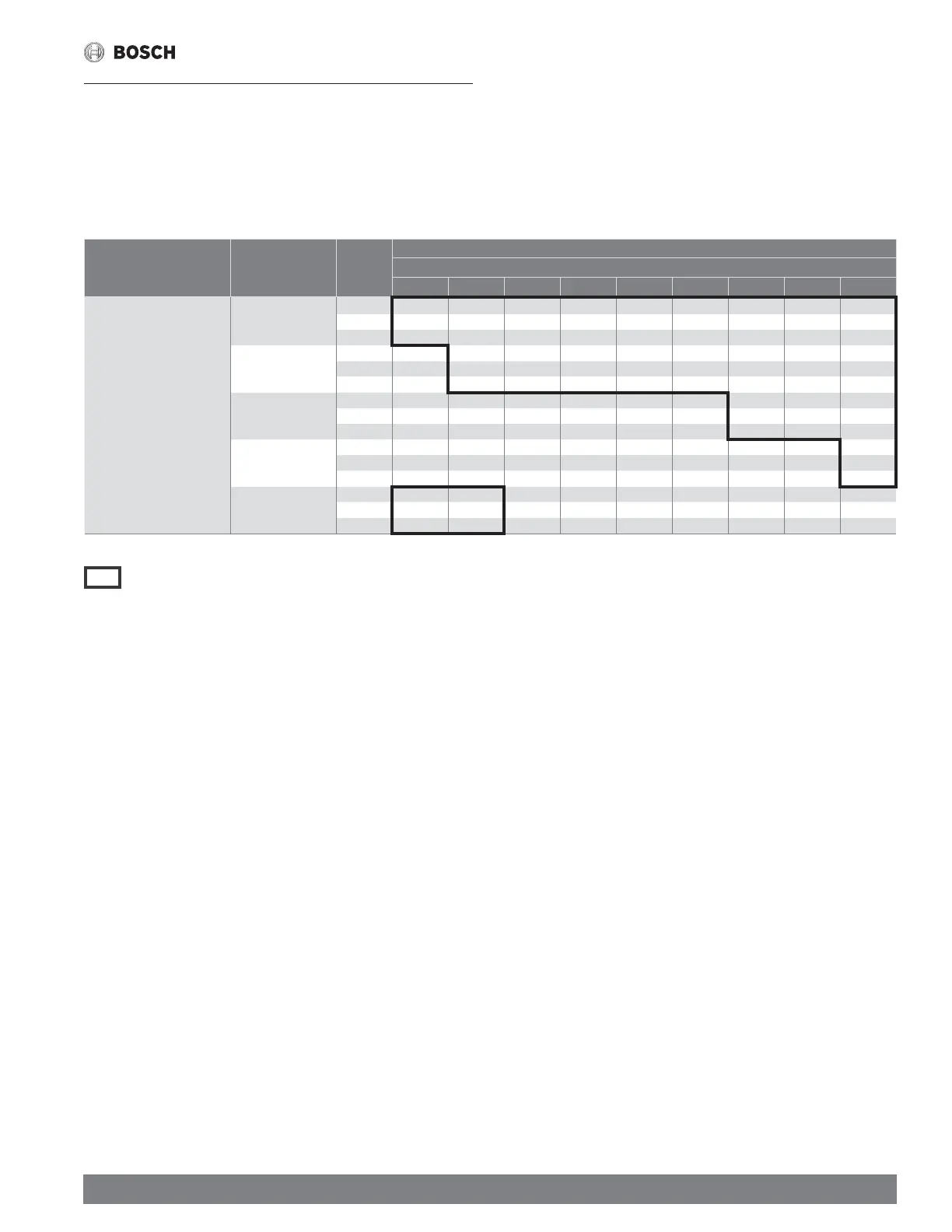

5 Airfl ow Performance

Airfl ow performance data is based on cooling performance with a coil and no fi lter

in place. Check the performance table for appropriate unit size selection.

External static pressure should stay within the minimum and maximum limits

shown in the table below in order to ensure proper operation of both cooling,

heating, and electric heating operation.

Model

Number

Motor Speed

SCFM

External Static Pressure-Inches W.C.[kPa]

0[0] 0.1[.02] 0.2[. 05] 0.3[.07] 0.4[.10] 0.5[.12] 0.6[.15] 0.7[.17] 0.8[.20]

BRBA-60HWD1N1-M18

Tap (1)

SCFM 1385 1300 1230 1136 1045 959 867 787 717

Watts 164 171 180 192 204 217 232 238 249

Amps

1.43

1.48 1.56 1.64 1.74 1.84 1.94 1.99 2.07

Tap (2)

SCFM

1489

1432 1352 1279 1172 1088 1013 934 863

Watts 206 211 223 233 241 257 269 283 295

Amps 1.76

1.80 1.89 1.96 2.02 2.13

2.24 2.34 2.43

Tap (3)

SCFM 1638

1572 1511 1440 1368 1293

1205 1137 1067

Watts 293 319 333 343 348 355 365 373 383

Amps 2.03 2.08 2.15 2.17 2.20 2.27

2.31 2.39

2.42

Tap (4)

SCFM 1964 1903 1840 1786 1724 1655

1591 1488

1427

Watts 435 450 466 479 494 507 521 535 551

Amps

3.51 3.67

3.71 3.86 3.96 4.07 4.17 4.27

4.38

Tap (5)

SCFM

2293 2225

2193 2133 2090 2011 1877 1755

1614

Watts 661 682 708 710 731 730 720 701 667

Amps

5.13 5.29

5.49 5.52 5.67 5.59 5.66 5.45 5.17

Table 6

Bold outlined areas represent airfl ow outside of the required 300-450 cfm

ton range.

NOTES:

1. The high stage airfl ow must be used as the rated airfl ow for the full load

operation of machine.

2. The rated airfl ow of systems without electric heater kits requires between

300 and 450 cubic feet of air per minute (CFM).

3. The rated airfl ow of systems with electric heater kits requires between 350

and 450 cubic feet of air per minute (CFM).

4. The air distribution system has the greatest eff ect on airfl ow. Therefore, the

contractor should use only industry-recognized procedures.

5. Duct design and construction should be carefully done. System

performance can be lowered dramatically through poor design or

workmanship.

6. Air supplier ducts should be located along the perimeter of the conditioned

space and properly sized. Improper location or insuffi cient air fl ow may

cause drafts or noise in the ductwork.

7. Installers should balance the air distribution system to ensure proper quiet

airfl ow to all rooms in the home. An air velocity meter or airfl ow hood can be

used to balance and verify branch and system airfl ow (CFM).

Loading...

Loading...