Installation 27/60

RE 92703-01-B/04.2018, A10VO, A10VSO, A10VNO, A10VSNO Series 52 and 53, Bosch Rexroth AG

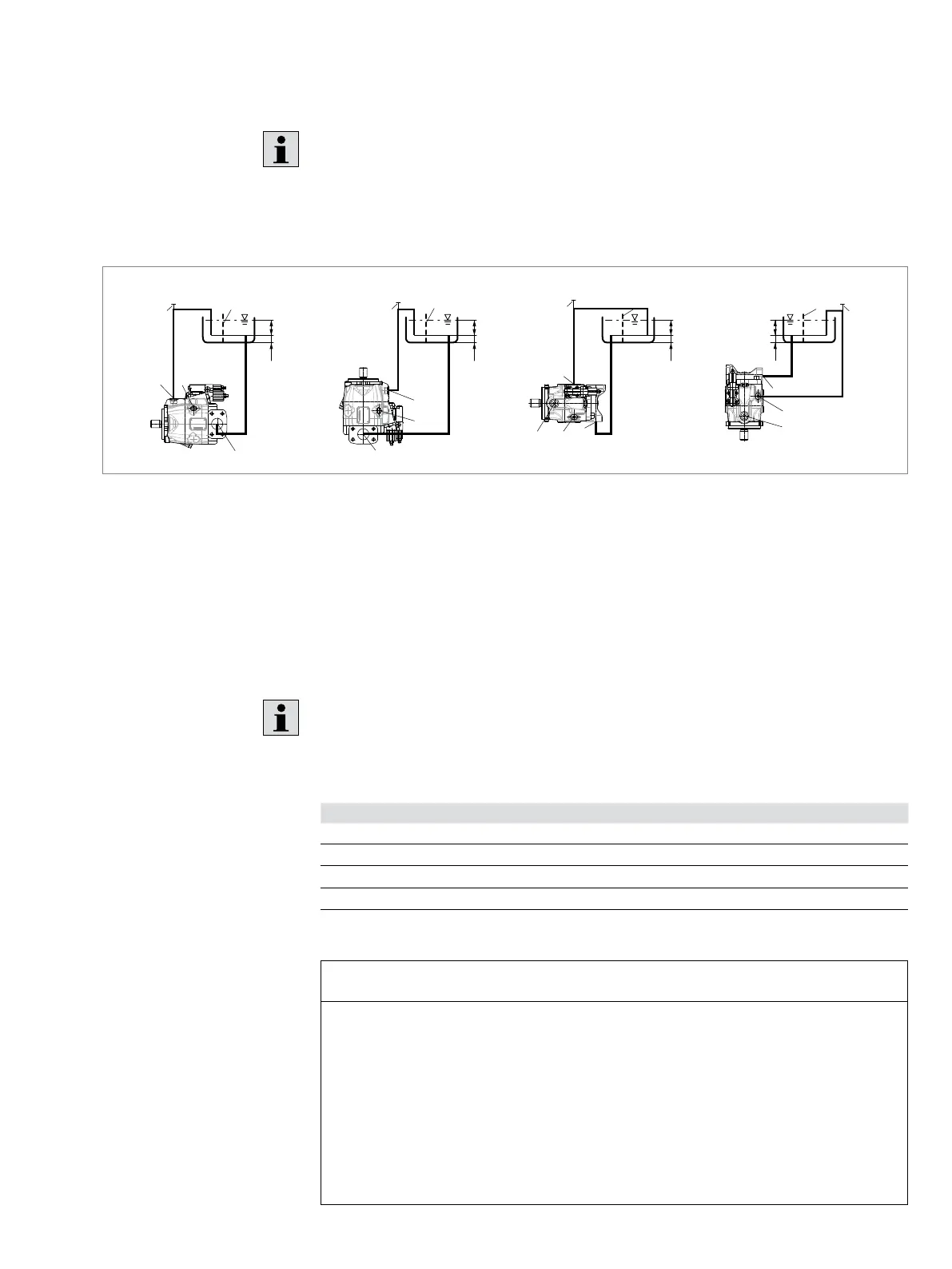

Recommended installation position: 1 and 3.

Because complete air bleeding and filling are not possible in installation positions

2 and 4, the axial piston unit should be air bled and filled in a horizontal position

prior to installation.

X

X

1

1)

2 3

2)

SB

L

1

L

S

h

t min

h

min

L

1

S

h

t min

h

min

SB

L

2

S

h

t min

h

min

F

SB

F

F

4

SB

L

1

S

h

t min

h

min

L

F

L

L

1

L

1)

A10VO: For NG10 and NG28 Series 52, L

1

is opposite, L must then be connected if necessary.

A10VNO: For NG45 and NG63 Series 52, L

1

is opposite, L must then be connected if necessary.

2)

Only Series 53.

Fig. 7: A10VO below-reservoir installation with installation positions 1-4

L, L

1

, L

2

Highest drain port h

t min

Min. required immersion depth

(200mm)

S Suction port h

min

Minimum required distance to

reservoir bottom (100mm)

F Filling/air bleeding SB Baffle (baffle plate)

PortF is part of the external piping and must be provided on the customer side

to make filling and air bleeding easier.

Table 8: Below-reservoir installation

Installation position Air bleed Filling

1 (drive shaft horizontal) F

S + L or L

1

2 (drive shaft up) F

S + L

1

3 (drive shaft horizontal) F

S + L

2

4 (drive shaft down) F

S + L or L

1

7.3.2 Inside-reservoir installation

NOTICE

Risk of damage with inside-reservoir installation!

To prevent damage to the axial piston unit, all plastic parts (e.g. protective plugs,

covers), except for the tamper-proof caps, must be removed prior to installation in

the reservoir.

▶ Remove all plastic parts, except for the tamper-proof caps, before you install the

axial piston unit in the reservoir. Make sure that no parts of them remain in the

reservoir.

▶ Remove the protective plug from the suction portS and open at least one

L port.

Loading...

Loading...