Do you have a question about the Bosch Rexroth LTS350D and is the answer not in the manual?

Defines the proper application and integration of the servo amplifiers.

Describes any use deviating from the specified intended use.

Outlines requirements for personnel performing assembly, commissioning, and operation.

Explains the format and meaning of safety instructions within the manual.

Provides general guidelines and precautions for safe operation and installation.

Explains how the servo amplifiers supply and control the EC motor's speed and current.

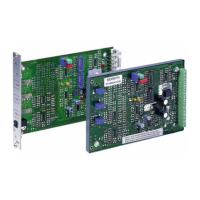

Details the front view components and interfaces of the servo amplifier.

Explains the graphic LC display, its values, and error codes.

Describes the function of the three LEDs on the servo amplifier front panel.

Details the XDS1 connection for the ErgoSpin hand-held nutrunner.

Details the XDS2 connection for the tightening spindle.

Explains the XDN3 interface for interrupting motor release via a closed contact.

Describes the function and positions of switch S2 on the board.

Lists the necessary tools for assembling the servo amplifiers.

Step-by-step instructions for safely installing the servo amplifiers.

Guidelines for maintaining cleanliness to prevent malfunctions.

States that amplifiers are maintenance-free if used as intended.

Directs users to find spare parts information and addresses.

Lists the screwdriver size needed for disassembly.

Provides steps for safely removing servo amplifiers, including safety precautions.

Advises on proper disposal methods to prevent environmental pollution.

Offers Rexroth service contact information for system know-how and problem resolution.

Provides information on accessing global service locations via the internet.

Lists essential information needed for efficient technical support.

Provides contact details for Bosch Rexroth AG sales and specific product lines.

Directs users to websites for information on tightening technology and sales offices.

The LTS350D/LTE350D servo amplifiers are system components designed to supply and control EC motors, with speed and current regulation managed within the amplifier itself. These devices are intended for integration into machines or systems, or for assembly with other components to form a complete machine or system. They are specifically designed for installation in a BT356 card rack or an SB35x system box, facilitating connection to a tightening spindle or an ErgoSpin hand-held nutrunner. The products are not ready-for-use machines and may only be commissioned once integrated into a compliant machine/system that adheres to the EC Machinery Directive.

The core function of the LTS350D/LTE350D servo amplifiers is to provide power and control to EC motors. This includes regulating both the speed and current of the motor. The device features a graphic LC display that shows result values such as torque, angle, gradient, and time, as well as error codes. The display is permanently backlit (LED) and shows texts in 4 lines, each with 8 characters. The contrast of the display can be adjusted via the BS350 operating system.

The servo amplifiers include several interfaces for connectivity and control:

The device also features three LEDs on the front panel to indicate operating status:

Loading...

Loading...