17

Test Procedures

EM90 and EM180 Test Procedures

1. Phase Test

1.1 Remove the grille, procedure 1.

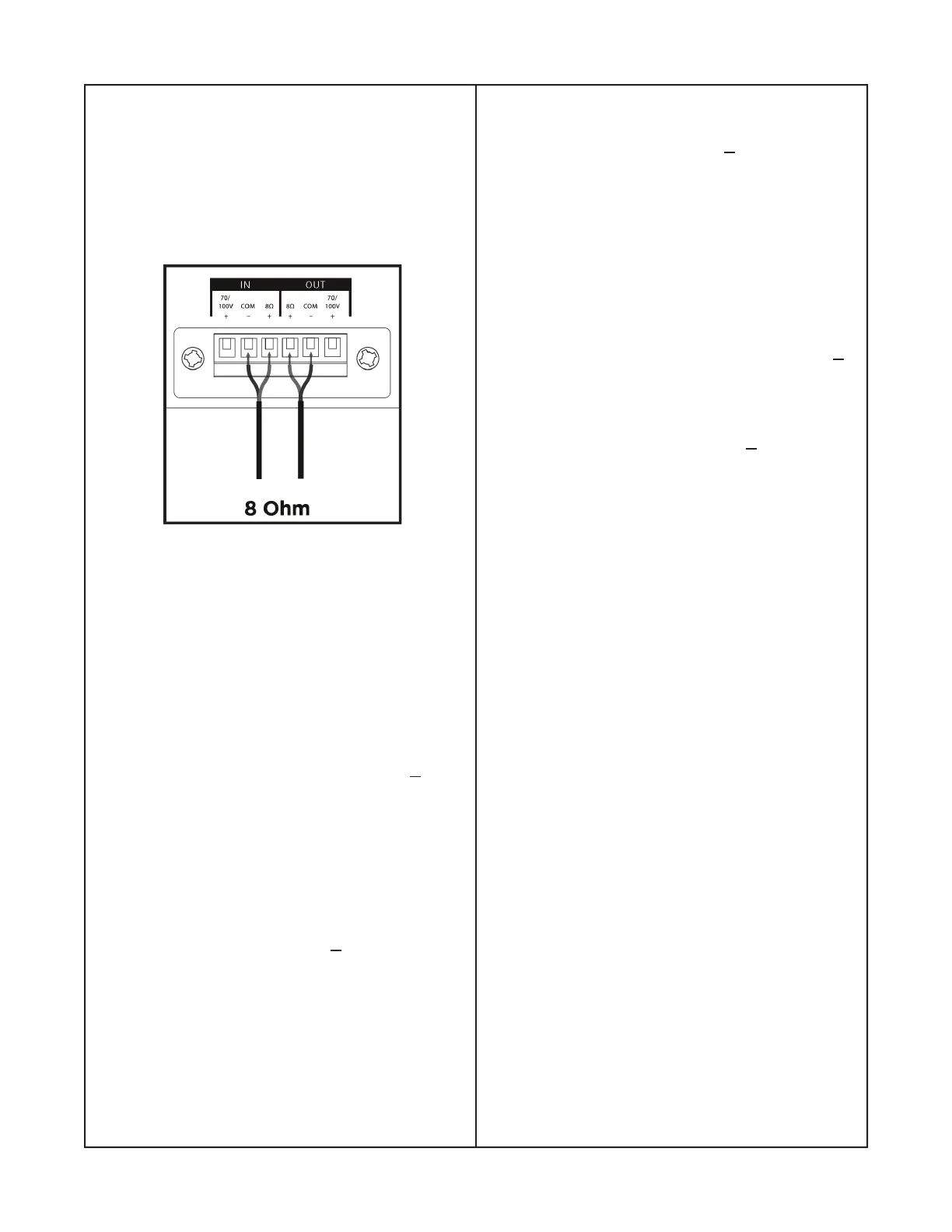

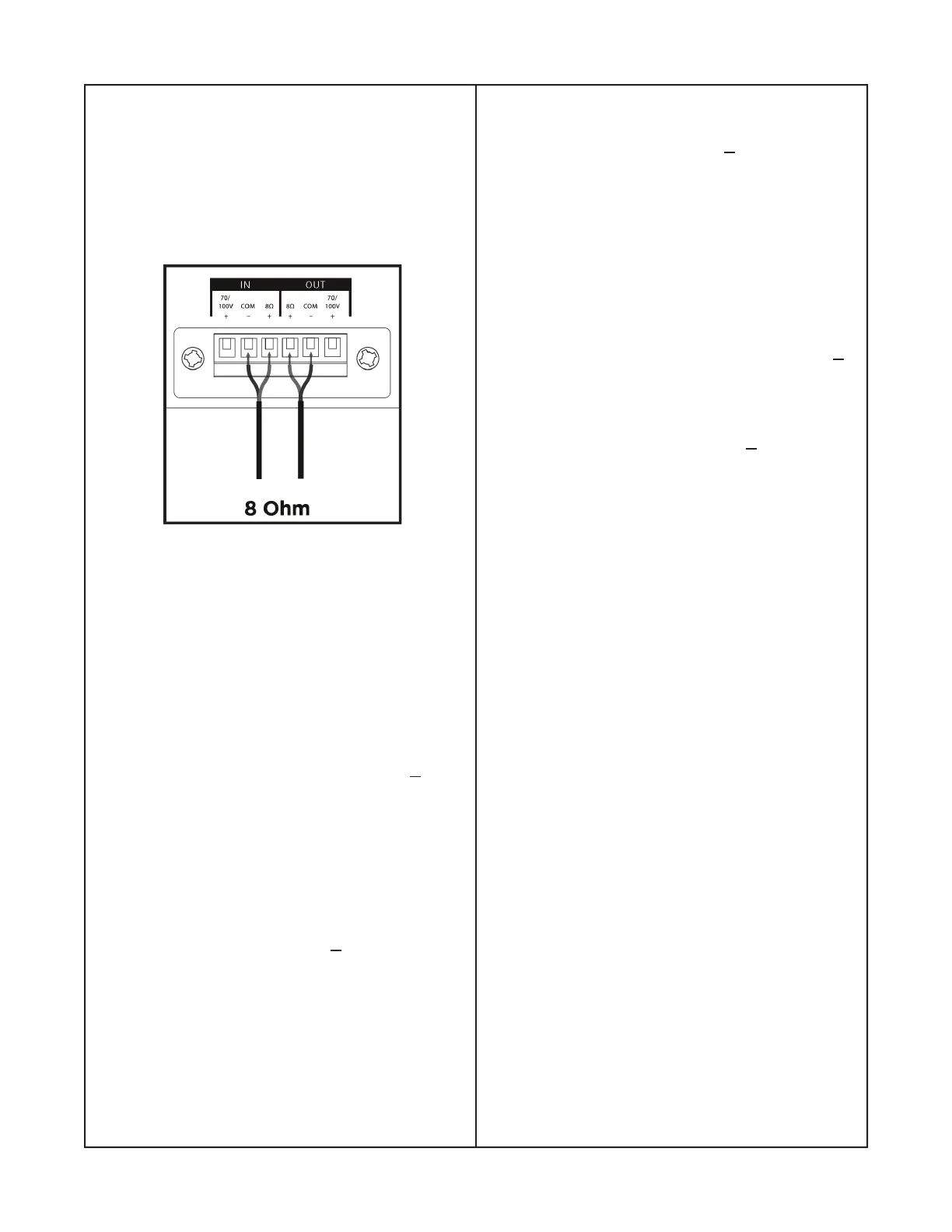

Note: For connection references, refer to the

Male 6 pin diagram posted on this page or

refer to page 8, fi gure 5, 8 Ohm diagram.

1.2 Place one hand on the woofer and gently

touch the dust cap or cone with fi ngers.

Momentarily apply a voltage of 9 Vdc, + 1Vdc

to the 8 ohm input terminal of the 6 pin plug

observing positive and negative polarity.

1.3 Verify the woofer moves outward.

Male, 6 pin plug diagram

3. Rub and Tick Test

3.1 Apply a 10 Hz, 10Vrms, + 1 Vrms signal

to the 8 ohm input.

3.2 Listen carefully for buzzes, rattles or

other extraneous noises from the driver,

woofer or the enclosure.

4. System Sweep with Grille Attached

4.1 Install grille. Apply a 70 Hz, 10 Vrms,

+

1Vrms

signal to the speaker input.

4.2 Change the oscillator frequency slowly

from 70 Hz to 3 KHz, 10 Vrms, + 1 Vrms into

the speaker. Listen carefully for any buzz or

rattle from the grille.

4.3 Replace any defective driver causing a

buzz noise or is defective. There must not

be buzzes, ticks, rubs, bottoming sounds, air

leaks or other unwanted acoustic noises.

2. Air Leak Test

2.1 Apply a 10 Hz, 10 Vrms, + 1 Vrms to the

8 ohm input.

2.2 Slowly increase the input frequency to 70

Hz.

2.3 Listen carefully for air leaks at all gaskets

and joints. Replace any speaker that has a

rubbing or ticking noise.

Equipment Required:

• Audio signal generator

• Male, 6 pin plug, Dinkle, PT: 792047-001S

• Audio amplifi er

Loading...

Loading...