ENGLISH

6

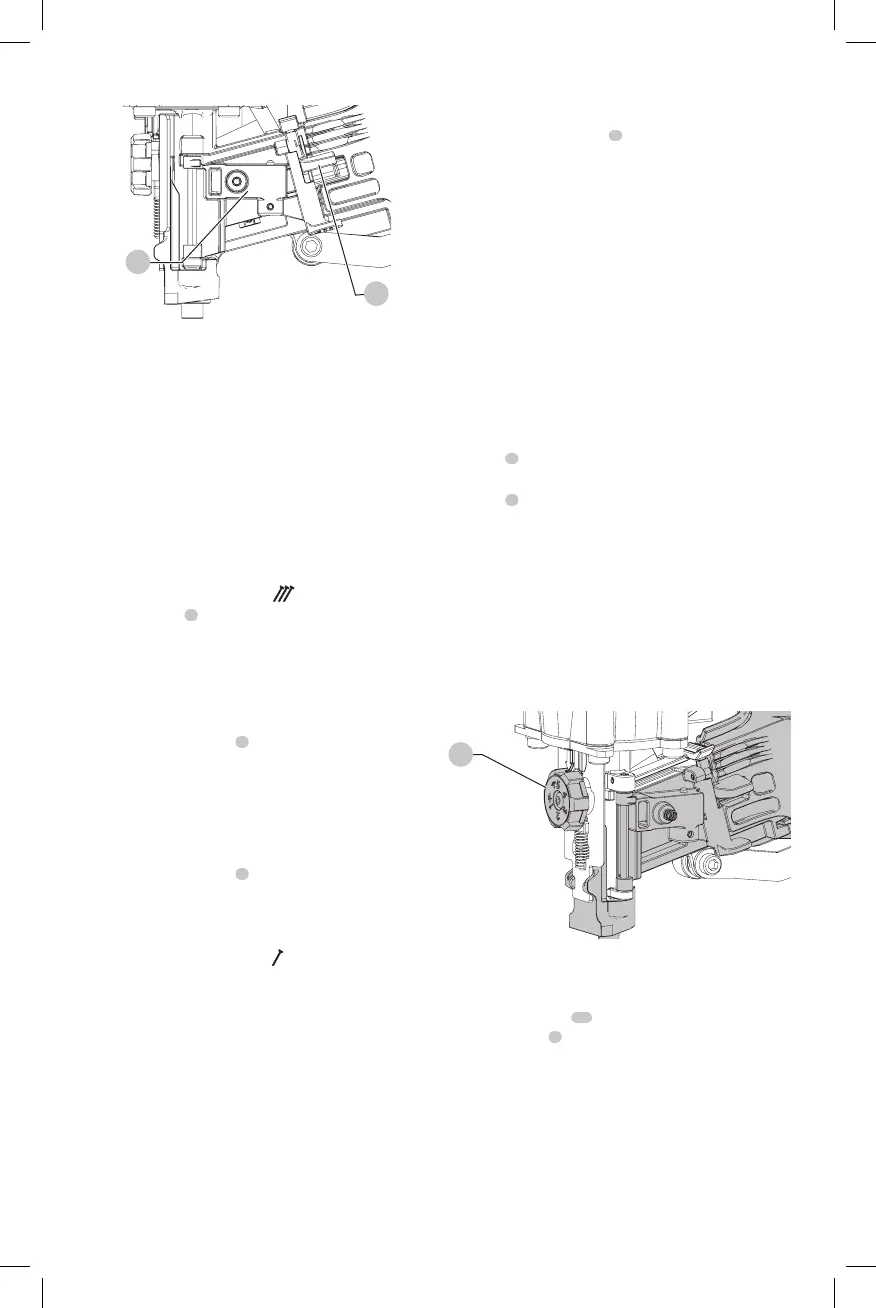

Fig. G

6

3

Actuating Tool (Fig. A)

WARNING: To reduce the risk of injury, ALWAYS

wear proper eye ANSI Z87.1 (CAN/CSA Z94.3) and

hearing protection ANSI S12.6 (S3.19) when operating

thistool.

WARNING: Keep fingers AWAY from the trigger when

not driving fasteners to avoid accidental actuation.

Never carry a tool with finger on the trigger. The tool

will drive a fastener if the contact trip is bumped

while the trigger isdepressed. Serious injury could

result if the trip accidentally contacted someone or

something, causing the tool tocycle.

Contact Actuation Trigger - (Fig. A)

The contact trigger

1

is intended for rapid fastening on flat,

stationarysurfaces.

Using the contact trigger, two methods are available: place

actuation and contactactuation.

To Operate the Tool Using the PLACE ACTUATION

Method

1. Depress the contact trip

4

against the worksurface.

2. Pull the trigger to drive thefastener.

3. Allow the tool to recoil off the work surface

To Operate the Tool Using the CONTACT ACTUATION

Method

1. Pull thetrigger.

2. Depress the contact trip

4

against the work surface. As

long as the trigger is pulled, the tool will drive a fastener

every time the contact trip is depressed. This allows the

user to rapidly drive multiple fastener insequence.

Single Sequential Trigger -

WARNING: Allow the tool to recoil off the work

surface after actuation. If the contact trip remains

depressed, a nail will be driven each time the trigger is

released and pulled, which could result in accidental

actuation, possibly causinginjury.

The sequential actuation trigger’s intended use is for

intermittent fastening where accurate fastener placement

isdesired.

To operate the tool in single sequential

actuationmode

1. Depress the contact trip

4

firmly against the

worksurface.

2. Pull thetrigger.

3. Allow the tool to recoil from the worksurface.

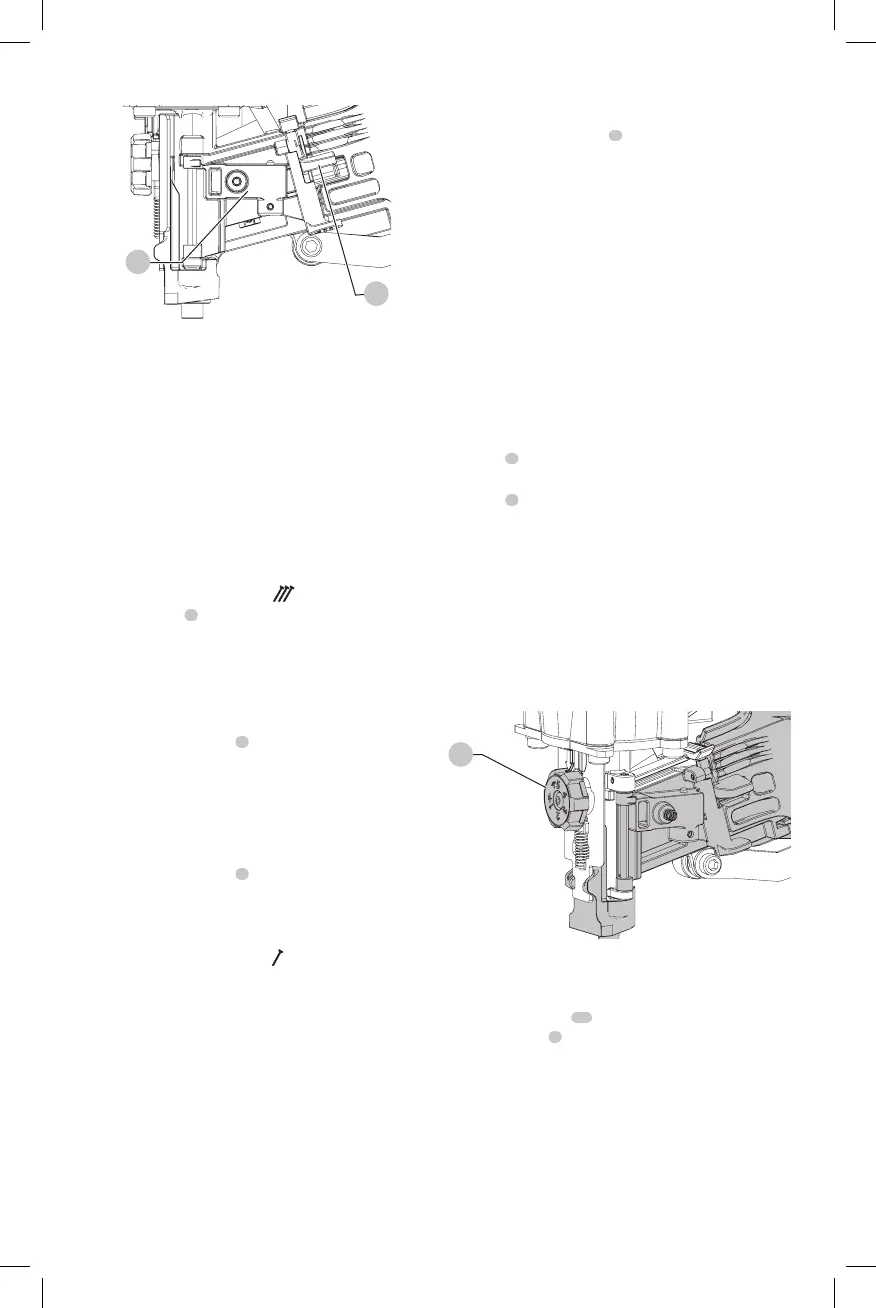

Adjusting Depth (Fig. H)

WARNING: To reduce risk of serious injury from

accidental actuation when attempting to adjust

depth, ALWAYS:

• Disconnect air supply.

• Avoid contact with trigger duringadjustments.

The depth that the fastener is driven can be adjusted using

the depth adjustment next to the trigger of the tool. The

depth of drive is factory adjusted to a nominal setting. Test

drive a fastener and check depth. If a change is desired:

1. To drive the nail shallower, rotate the depth adjustment

wheel

5

to theright.

2. To drive a nail deeper, rotate the depth adjustment

wheel

5

to theleft.

The adjustment wheel has detents every 1/4 turn. Test drive

another fastener and check depth. Repeat as necessary to

achieve desired results. The amount of air pressure

required will vary depending on the size of the fastener

and the material being fastened. Experiment with the air

pressure setting to determine the lowest setting that will

consistently perform the job at hand. Air pressure in excess

of that required can cause premature wear and/or damage

to thetool.

Fig. H

5

Shingle Guide (Fig. I, J)

Adjust Shingle Guide

1. Loosen the screw

13

with a hex wrench and slide the

shingle guide

7

to the desiredposition.

2. Retighten the screw with firmly.

Loading...

Loading...