7

ENGLISH

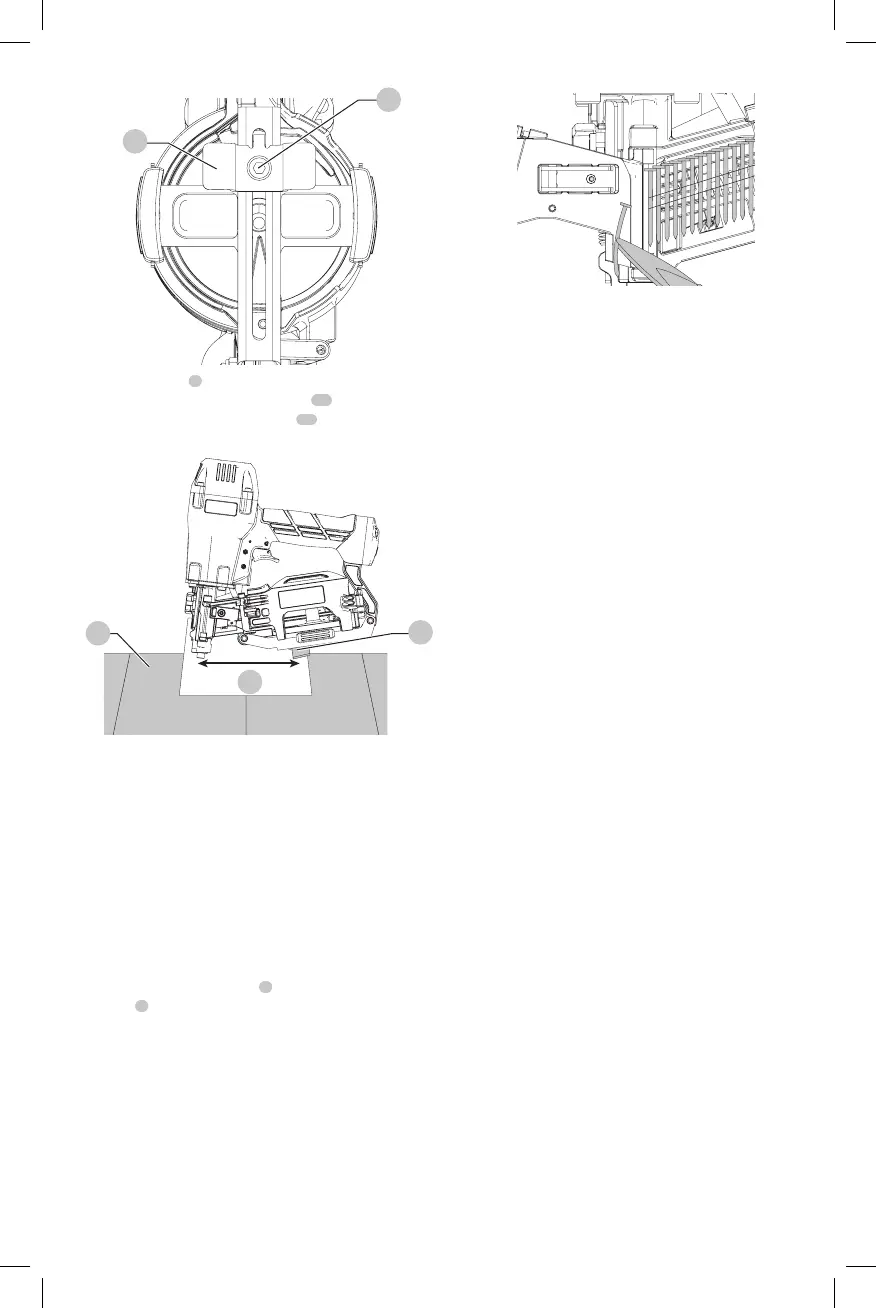

Fig. I

7

13

The shingle guide

7

can be used as an aid to position the

shingle being nailed a specific distance

14

from the front

edge of the previous row of shingles

15

asshown.

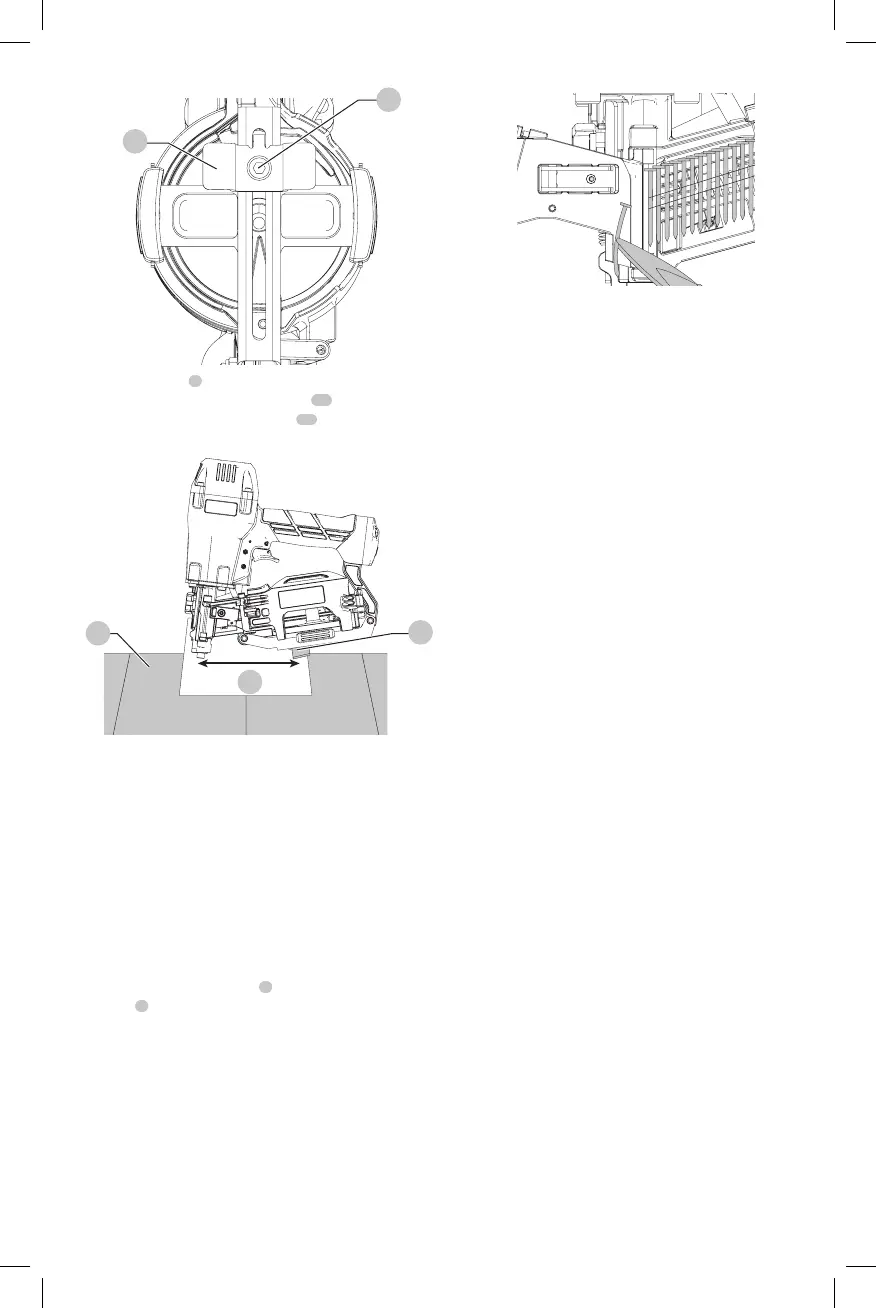

Fig. J

14

15

7

Clearing a Jammed Nail (Fig. A, K)

WARNING: To reduce the risk of personal

injury, disconnect tool from air supply before

performing maintenance, when loading or

removing fasteners, clearing a jammed fastener,

leaving work area, moving tool to another

location or handing the tool to anotherperson.

If a nail becomes jammed in the nosepiece, keep the tool

pointed away from you and follow these instructions

toclear:

1. Disconnect the air supply from thetool.

2. Lift the canister door latch

3

to open the nail guide

door

6

.

3. Open the canisterdoor.

4. Remove the jammednail.

5. Correct any deformation that may have occurred to the

nailcoil.

NOTE: Should nails continue to jam frequently in

nosepiece, have tool serviced by an authorized BOSTITCH

servicecenter.

Fig. K

Cold Weather Operation

For cold weather operation, near and below freezing,

the moisture in the air line may freeze and prevent tool

operation. We recommend the use of winter formula air tool

lubricant or permanent antifreeze (ethylene glycol) as a cold

weatherlubricant.

CAUTION: Do not store tools in a cold weather

environment to prevent frost or ice formation on the

tools operating valves and mechanisms that could

cause toolfailure.

NOTE: Some commercial air line drying liquids are harmful

to “O”-rings and seals—do not use these low temperature

air dryers without checkingcompatibility.

Hot Weather Operation

Tool should operate normally. However, keep tool out

of direct sunlight as excessive heat can deteriorate

bumpers, O-rings and other rubber parts resulting in

increasedmaintenance.

MAINTENANCE

WARNING: To reduce the risk of personal

injury, disconnect tool from air supply before

performing maintenance, when loading or

removing fasteners, clearing a jammed fastener,

leaving work area, moving tool to another

location or handing the tool to anotherperson.

Cleaning

WARNING: Blow dirt and dust out of all air vents with

clean, dry air at least once a week. To minimize the risk

of eye injury, always wear ANSI Z87.1 approved eye

protection when performingthis.

WARNING: Never use solvents or other harsh

chemicals for cleaning the non-metallic parts of

the tool. These chemicals may weaken the plastic

materials used in these parts. Use a cloth dampened

only with water and mild soap. Never let any liquid

get inside the tool; never immerse any part of the tool

into aliquid.

Replacement Parts

BOSTITCH replacement parts are recommended. Do not

use modified parts or parts which will not give equivalent

performance to the originalequipment.

Loading...

Loading...