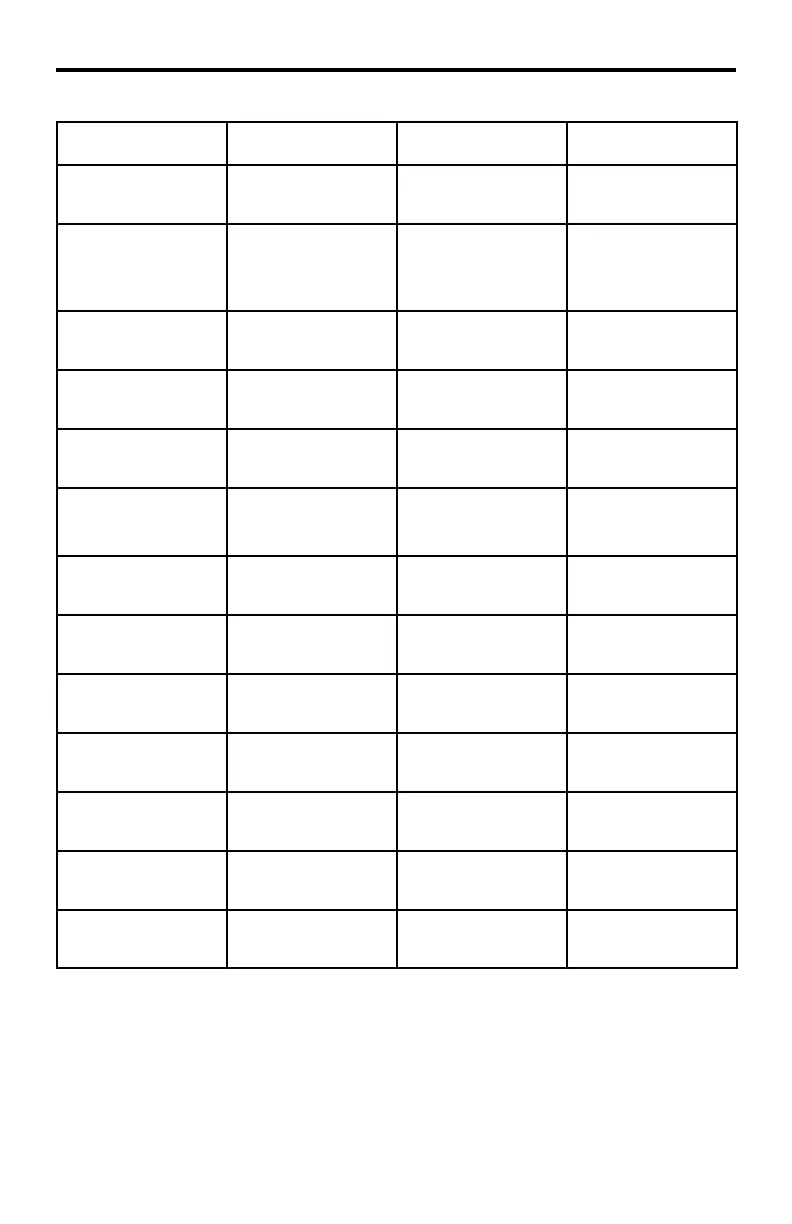

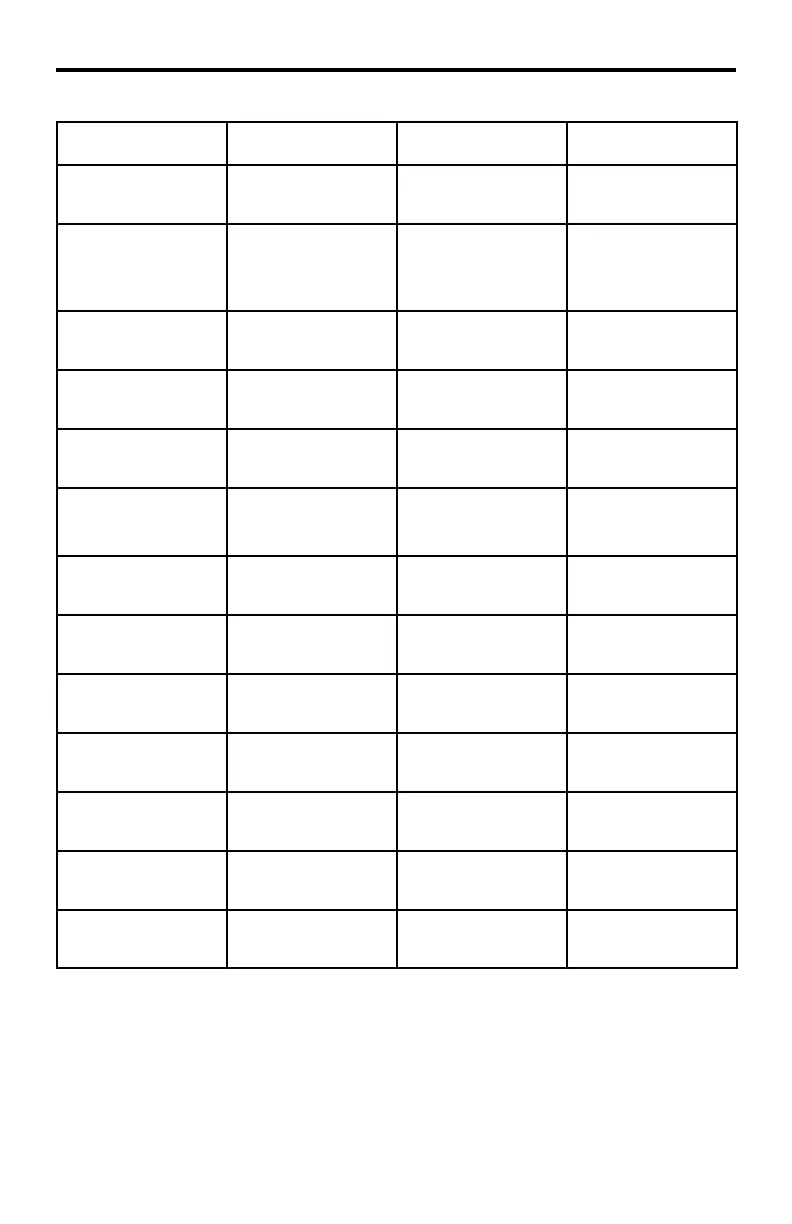

-14-

MAINTENANCE CHECKLIST

Maintenance Benefit Procedure Service Interval

I

nspect trigger performance

E

nsure trigger system is in

proper working order

R

efer to Tool Operation Check

section in this manual

D

aily

Drain condensation from air

compressor tanks and air filters

(

if present)

Prevents accumlation of

moisture that can impede tool

p

erformace

Open drain cock on tanks and

air filters and drain all

c

ondensate

Daily

Clean magazine assembly Prevents accumlation of debris

t

hat could cause a jam

Blow clean with compressed air Daily

Clean nose assembly Prevents accumlation of debris

that could cause a jam

Blow clean with compressed air Daily

Ensure all fasteners remain

t

ight

Prevent loose parts Tighten all fasteners with

a

ppropriately sized hex wrench

Weekly

Check/clean air inlet air filter Maintains proper air flow to

engine for peak performance.

Remove end cap and use

compressed air blow gun to

blow filter clean. Replace filter

as required.

25,000 Fasteners, or monthly -

if used in dusty location

Replace no-mar tip Prevents marks in softwood

applications

Remove worn no-mar tip and

replace with a new tip (a spare tip is

located on the magazine)

25,000 Fasteners

Replace swivel air fitting Maintains proper air flow to

engine for peak performance

Remove worn swivel air fitting

and replace with new swivel

fitting

50,000 Fasteners

Replace piston/driver assembly Maintains consistent drive

quality

Refer to replacement part kit

instructions

250,000 Fasteners

Replace O-rings Maintains engine for peak

performance

Refer to replacement part kit

instructions

250,000 Fasteners

Replace bumper Maintains engine for peak

performance

Refer to replacement part kit

instructions

250,000 Fasteners

Replace headvalve Maintains engine for peak

performance

Refer to replacement part kit

instructions

250,000 Fasteners

Replace engine cylinder Maintains engine for peak

performance

Refer to replacement part kit

instructions

500,000 Fasteners

Loading...

Loading...