4

MCN150 / MCN250 / MCN250S TOOL SPECIFICATIONS

All screws and nuts are metric.

FASTENER SPECIFICATIONS:

MCN150: Uses a 35° paper collated full round head metal connector nails, in lengths of 1-1/2” (38mm) and

shank diameters of .131”, .148”.

MCN250 & MCN250S: Uses a 35° paper collated full round head metal connector nails, in lengths of 1-1/2”

and 2-1/2” (38 - 64mm) and shank diameters of .131”, .148”, .162”.

TOOL AIR FITTING:

This tool uses a 1/4” N.P.T. male plug. The inside diameter should be .200” (5mm) or larger. The fitting must

be capable of discharging tool air pressure when disconnected from the air supply.

OPERATING PRESSURE:

70 to 120 p.s.i.g. (4.9 to 8.4 kg/cm2 ). Select the operating pressure within this range for best fastener

performance. DO NOT EXCEED THIS RECOMMENDED OPERATING PRESSURE.

AIR CONSUMPTION:

The MCN150 requires 6.7 cubic feet per minute (190 liters per minute) of free air to operate at the rate of 100

nails per minute, at 80 p.s.i. (5.6 kg/cm

2

). Take the actual rate at which the tool will be run to determine the

amount of air required. For instance, if your fastener usage averages 50 nails per minute, you need 50% of the

6.7 c.f.m. (190 liters per minute) which is required to operate the tool at 100 nails per minute.

The MCN250 & MCN250S requires 7.7 cubic feet per minute (218 liters per minute) of free air to operate at the

rate of 100 nails per minute, at 80 p.s.i. (5.6 kg/cm

2

). Take the actual rate at which the tool will be run to

deteremine the amount of air required. For instance, if you fastener usuage averages 50 nails per minute, you

need 50% of the 7.7 c.f.m. (218 liters per minute) which is required to operate the tool at 100 nails per minute.

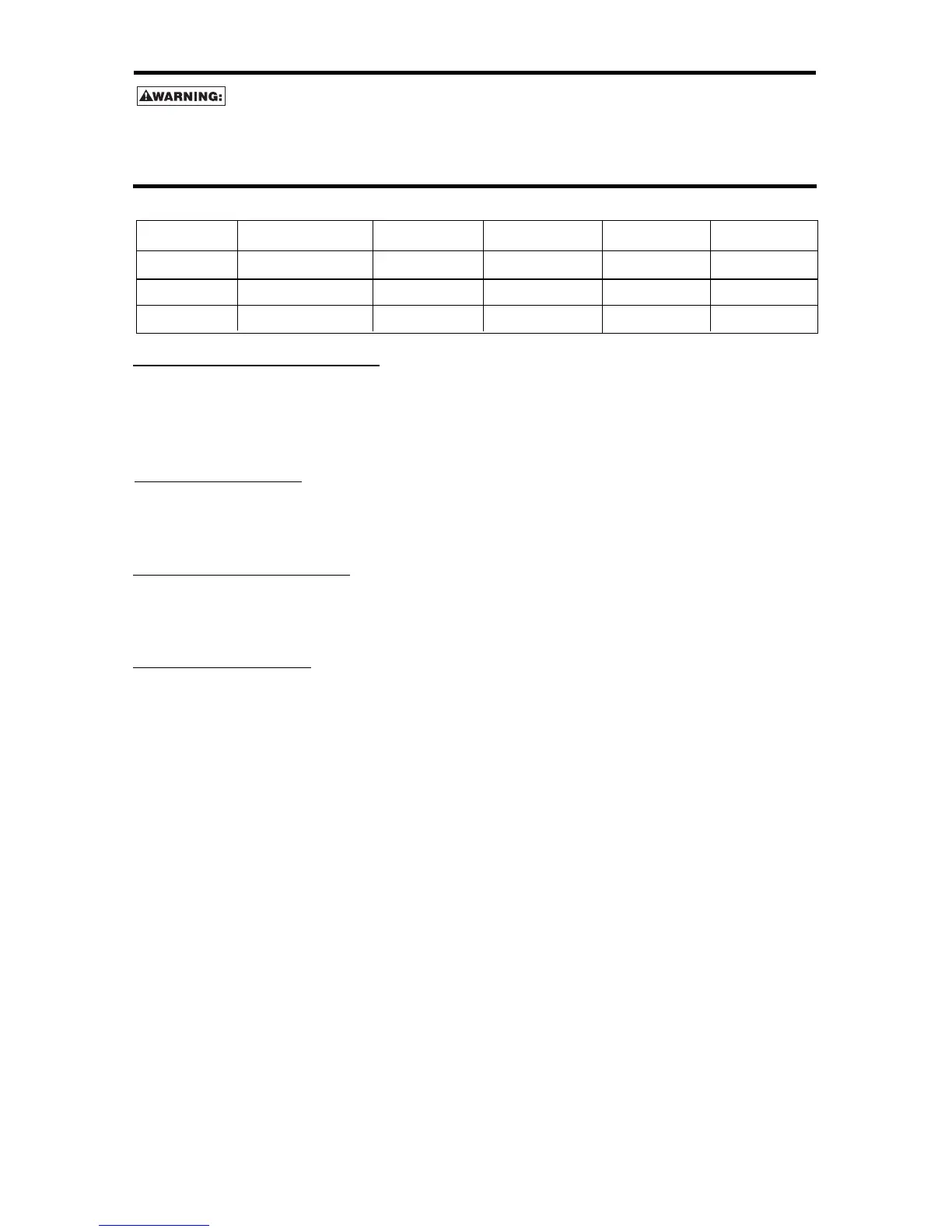

MODEL

TOOL

LENGTH HEIGHT WIDTH WEIGHT

ACTUATION

MCN150 Sequential Trip 11-3/4” (296 mm) 10-1/2” (267 mm) 3-1/2” (85.7 mm) 4.3 lb. (1.95 kg.)

MCN250 Sequential Trip 16-1/8” (410 mm) 14” (356 mm) 3-1/2” (85.7 mm) 6.0 lb. (2.72 kg.)

MCN250S Sequential Trip 11-3/4” (296 mm) 14” (356 mm) 3-1/2” (85.7 mm) 5.5 lb. (2.59 kg.)

MAINTAINING THE TOOL

When working on air tools note the warnings in this manual and use extra care when

evaluating problem tools.

Loading...

Loading...