22

7. Connection

7.3 Piping

Connect the supply and drain pipes (supplied by customer) in accordance with the

installation details. Steam, compressed air and water must be equipped with stop valves.

Water connection must be according to DIN 1988. To avoid sound conduction through

solids, an intermediate piece - made of flexible metal hose - can be connected and the

pipe holders can be insulated.

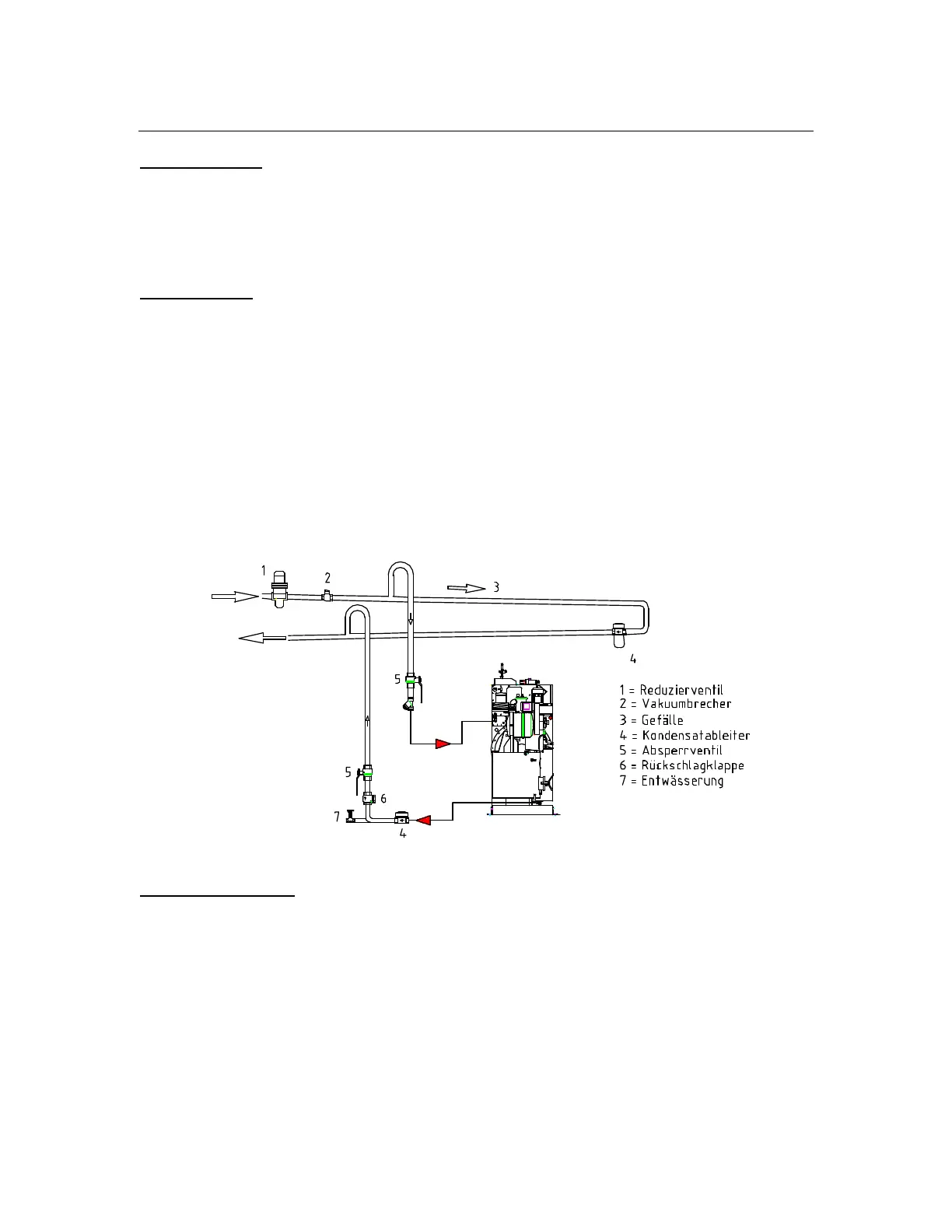

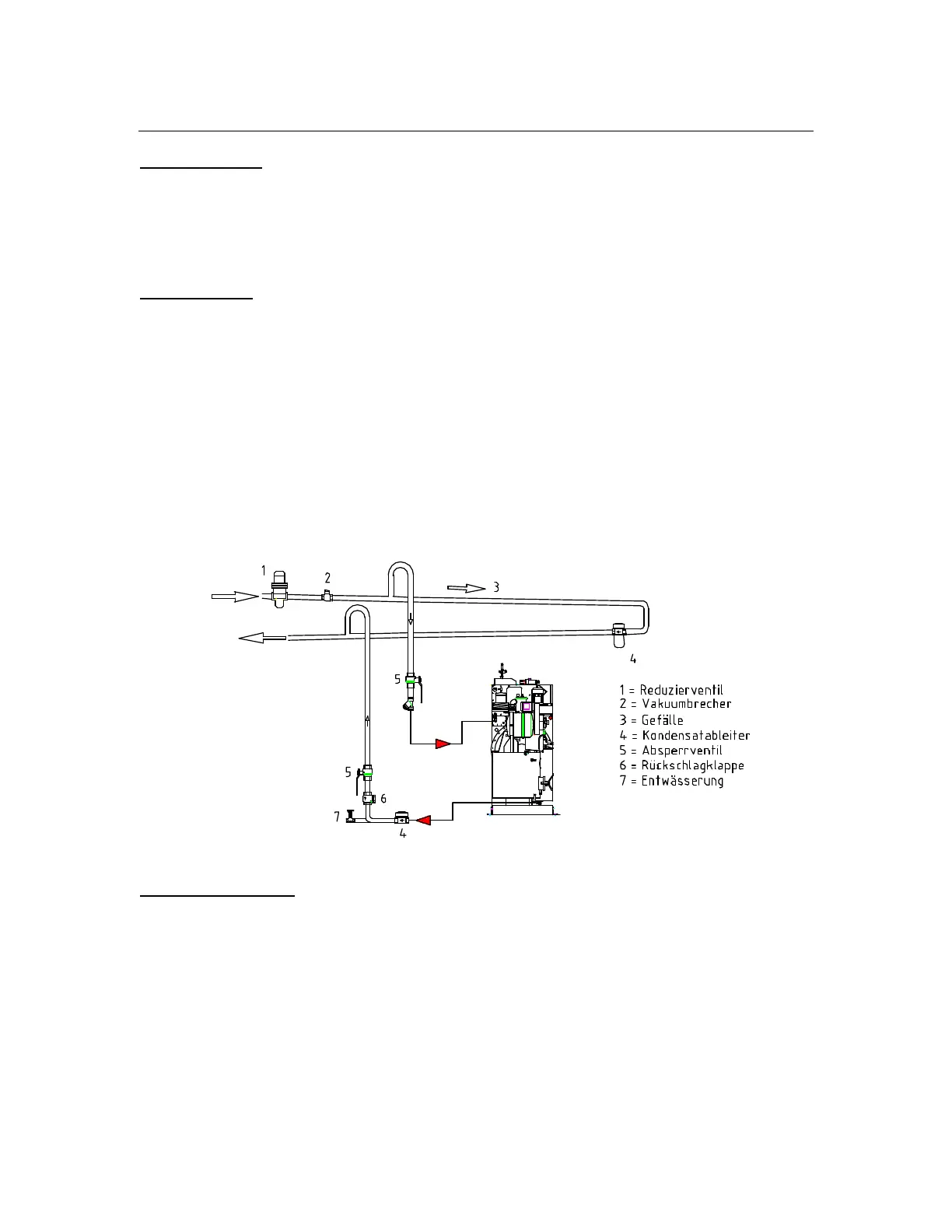

7.3.1 Steam

Insulate the installation and connection pipes. Avoid the use of asbestos!

Operating pressure 4 - 5 bar (58 - 72.5 psi) saturated steam. At a pre-pressure of

more than 5 bar (72.5 psi) a reducing valve with pressure gauge must be installed

and set in a way that the admissible max. perc temperature of 150 °C (302 °F)

(please measure!) is not exceeded. (Danger of solvent decomposition and machine damage!)

Steam peak demand: P 240 /P 300

P 300 USA /P 350 USA

(steam generator size) 0.6 kg/min. 1.3 lb/min.

________________________________________________________________________

703868-17-0

7.3.2 Condensate

Install insulated condensation line with a slope, away from machine.

In case of an ascending slope check valve and drainage must be at the lowest point.

Important: Condensate counter-pressure must be at least

1.5 bar (21.8 psi) below the steam inlet pressure.

Loading...

Loading...