23

7. Connection

7.3.3 Cooling water supply

7.3.3.1 City cooling water connection

Fit the line to the machine without reduction of cross section and if possible

without bends. The heat balance of the machine is optimally set to 12 °C (53.6 °F)

cooling water inlet temperature and a uniform pressure of 2 - 4 bar (29 - 58 psi).

(Minimum pressure 2,0 bar (29 psi); Maximum pressure 6,0 bar (87 psi).

P 240 P 300

P 300 USA P 350 USA

________________________________________________________________________

Cooling water peak demand

2 - 4 bar /29 - 58 psi (12 °C /53.6 °F). l/min. 7.0 9.0

USgal/min. 1.8 2.4

For safety reasons a water flowback stop and venting device should be installed.

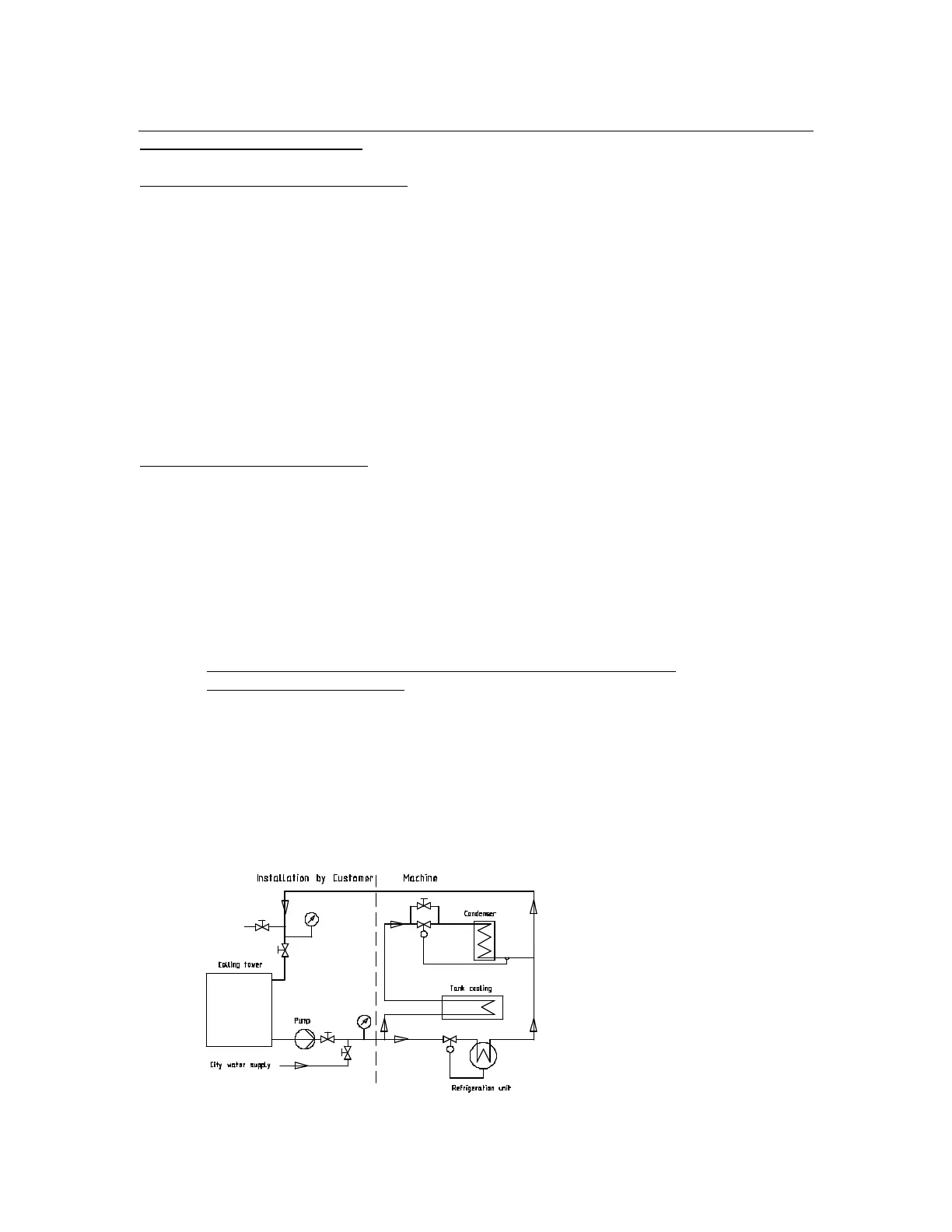

7.3.3.2 Cooling tower operation

We recommend cooling towers from our partner company Geiger D-78224 Singen

for P 240 /P 300 USA: Type WH5-W6

P 300 /P 350 USA: Type WH7-W6

At a cooling tower operation the pipes to and from the machine must be at least

one nominal size larger. Respectively the dimensions must be according to the

nominal size of the pump. Inlet temperatures should not exceed 24 °C (75.2 °F)

as otherwise solvent consumption would increase and the drying time could be longer.

If the temperatures of the cooling water are too high the refrigeration unit may be overloaded.

Water pressure must be adapted to the higher inlet temperature up to

double the max. requirement.

With re-chilling the correct installation is especially important. Among other things,

the following must be taken into account: cooler performance, switch-over to public city

water supply, low temperature storage, pump size, cooling water valve by-pass.

The cooling water regulator for the distillation must be by-passed (continuous water flow).

The cooling water regulator of the refrigeration unit should be exchanged with a regulator

one size larger.

The cooling water supply respectively the feeding of the cooling tower must be from the

city water net or from a soft water system.

703868-26-0

Loading...

Loading...