40

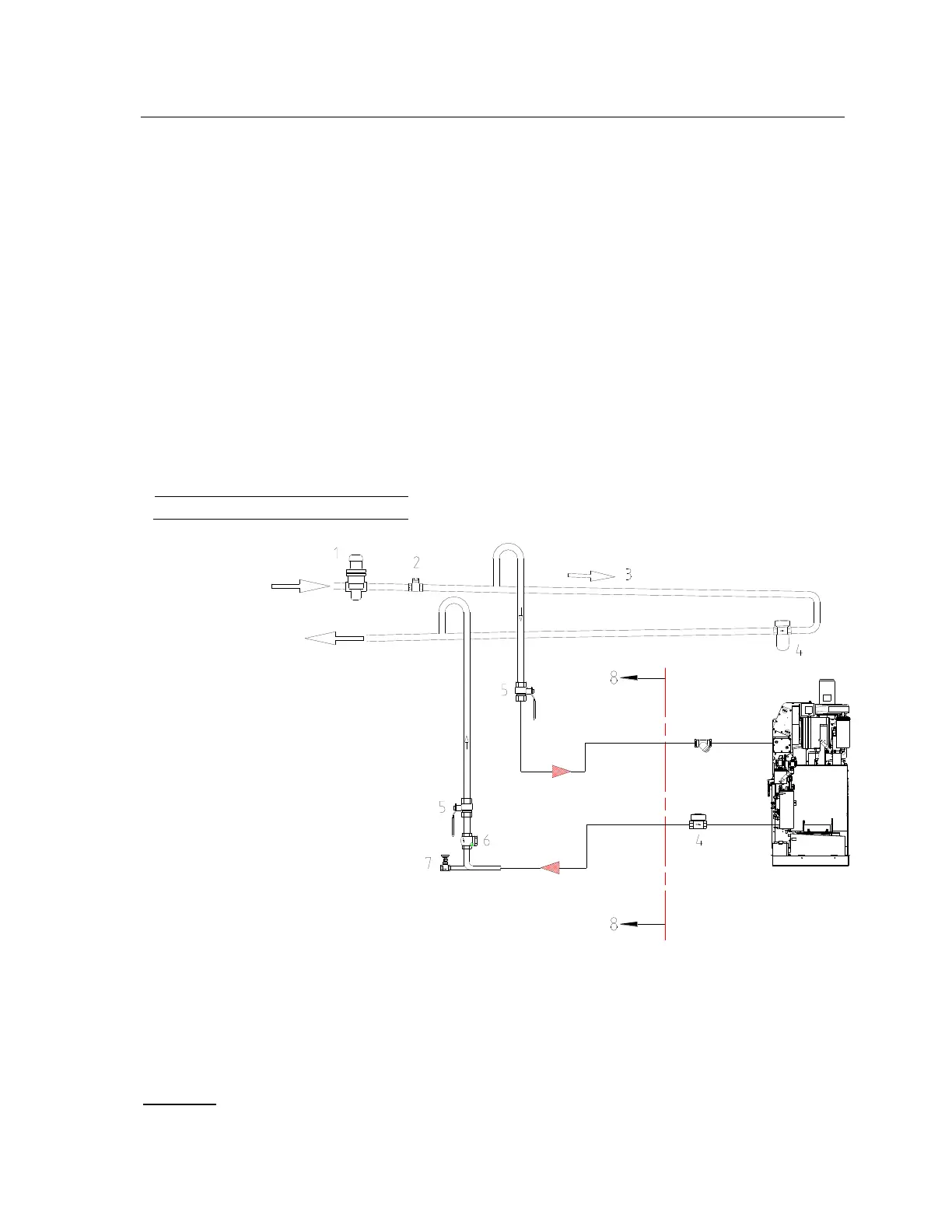

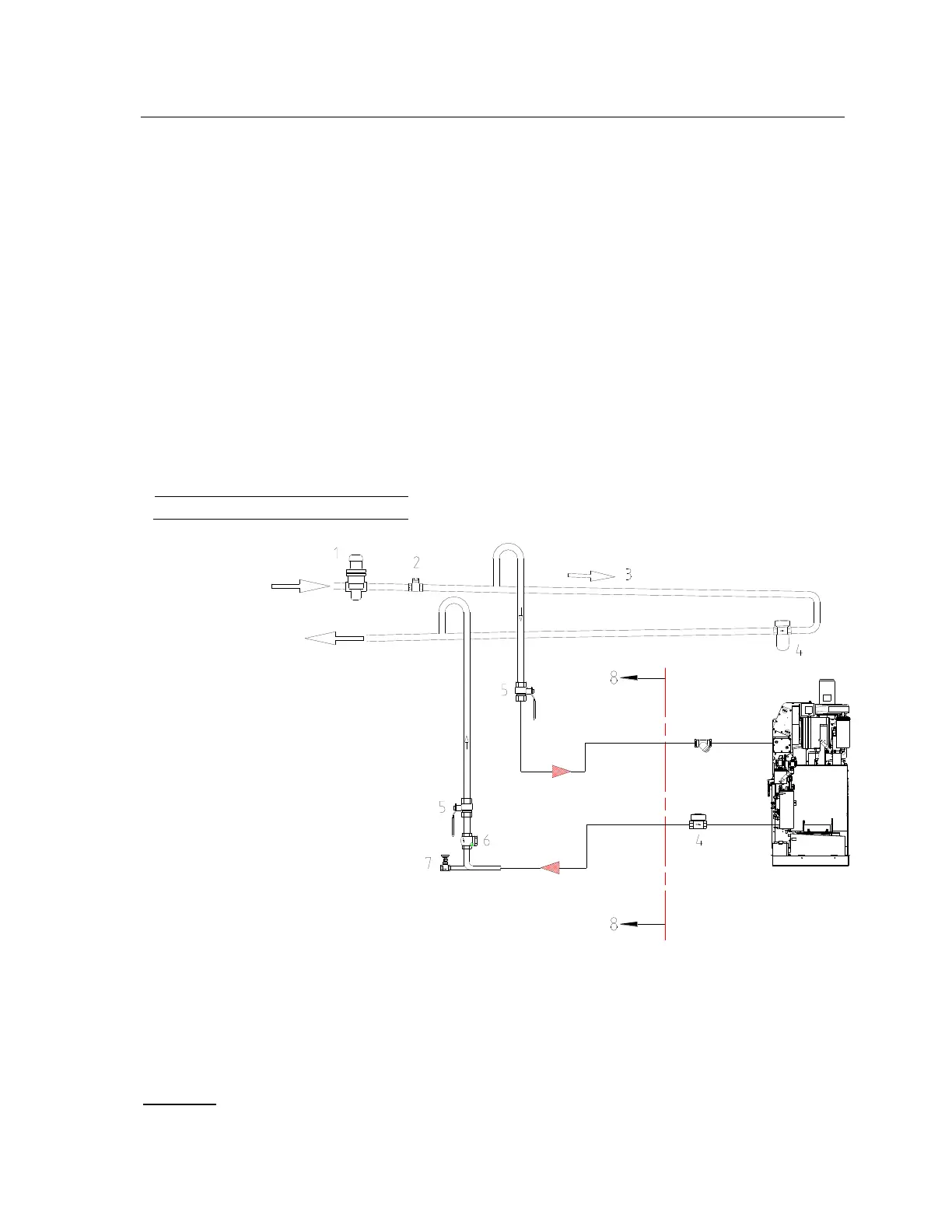

P12-P15-P18

7 Connection 7

Connect the on-site supply and drain lines according to the information in the dimensioned drawing.

Steam, condensate, compressed air and water must be equipped with stop valves. Follow DIN 1988

when connecting the water. To avoid transmission of structure-borne noise, you can connect the

pipelines with a spacer of flexible metal tubing and insulate the pipe holders.

7.2.1 Steam

Insulate the installation und connection units.

Operating pressure is 4 - 5 bar (58 - 72.5 psi) saturated steam.

If the admission pressure is more than 5 bar (72.5 psi), build in a reducing valve with pressure

gauge and set it so that the highest permissible temperature for Perc of 150 °C (302 °F)

(measure!) is not exceeded (danger of solvent decomposition and damage to the machine).

Peak steam demand (large steam generator):

P12/P15/P18

1 = reducing valve

2 = vacuum breaker

3 = descending slope

4 = steam trap

5 = stop valve

6 = non-return valve

7 = drain

8 = provided by customer

707767-12-0

7.2.2 Condensate

Install insulated condensate line so that it slopes away from the machine. If there is an ascending slope,

put a non-return valve and drain at the lowest point.

Attention: Condensate counter-pressure must be at least 1.5 bar (21.8 psi) below the

incoming steam pressure.

Loading...

Loading...