57

P21/P26/P30

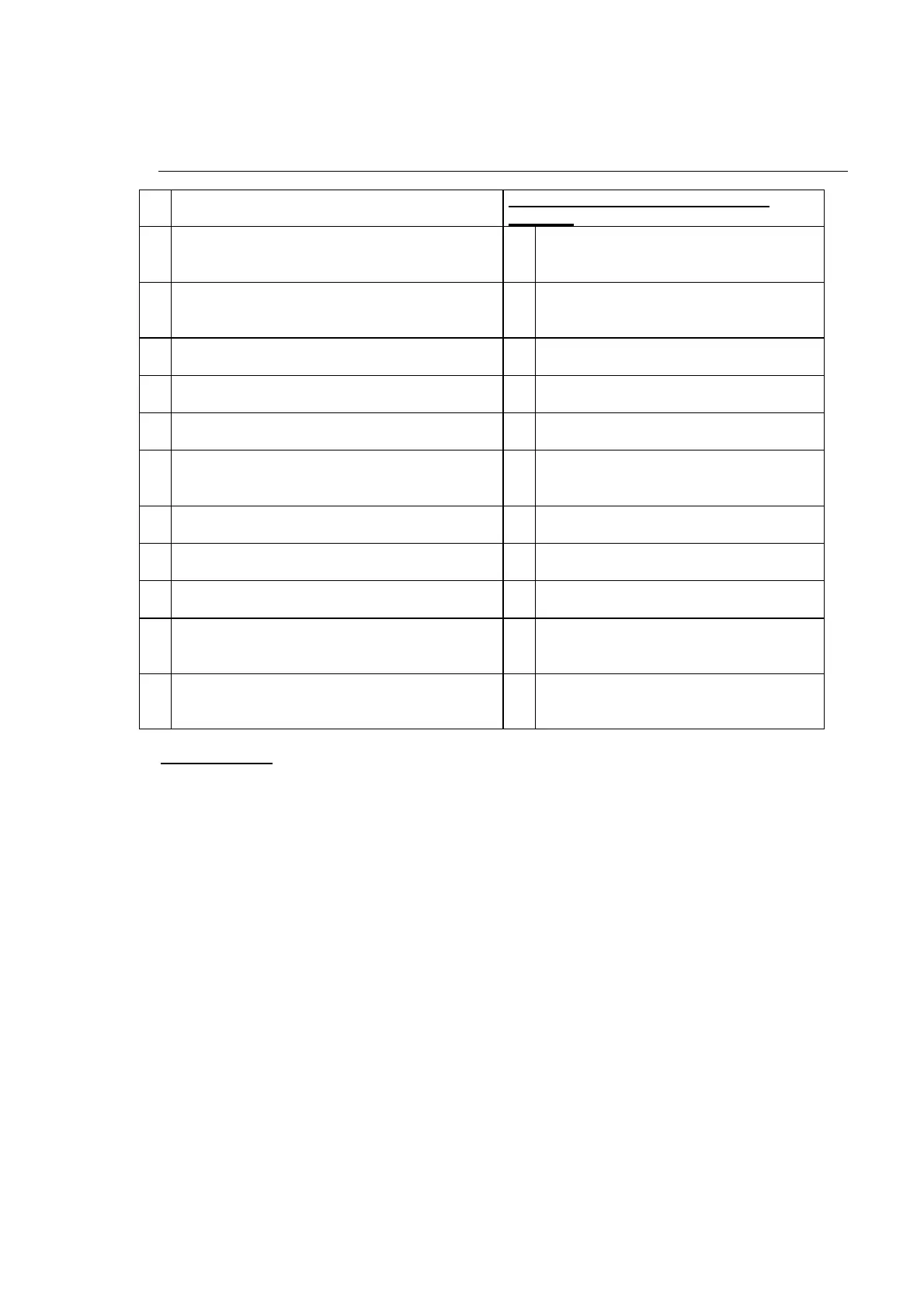

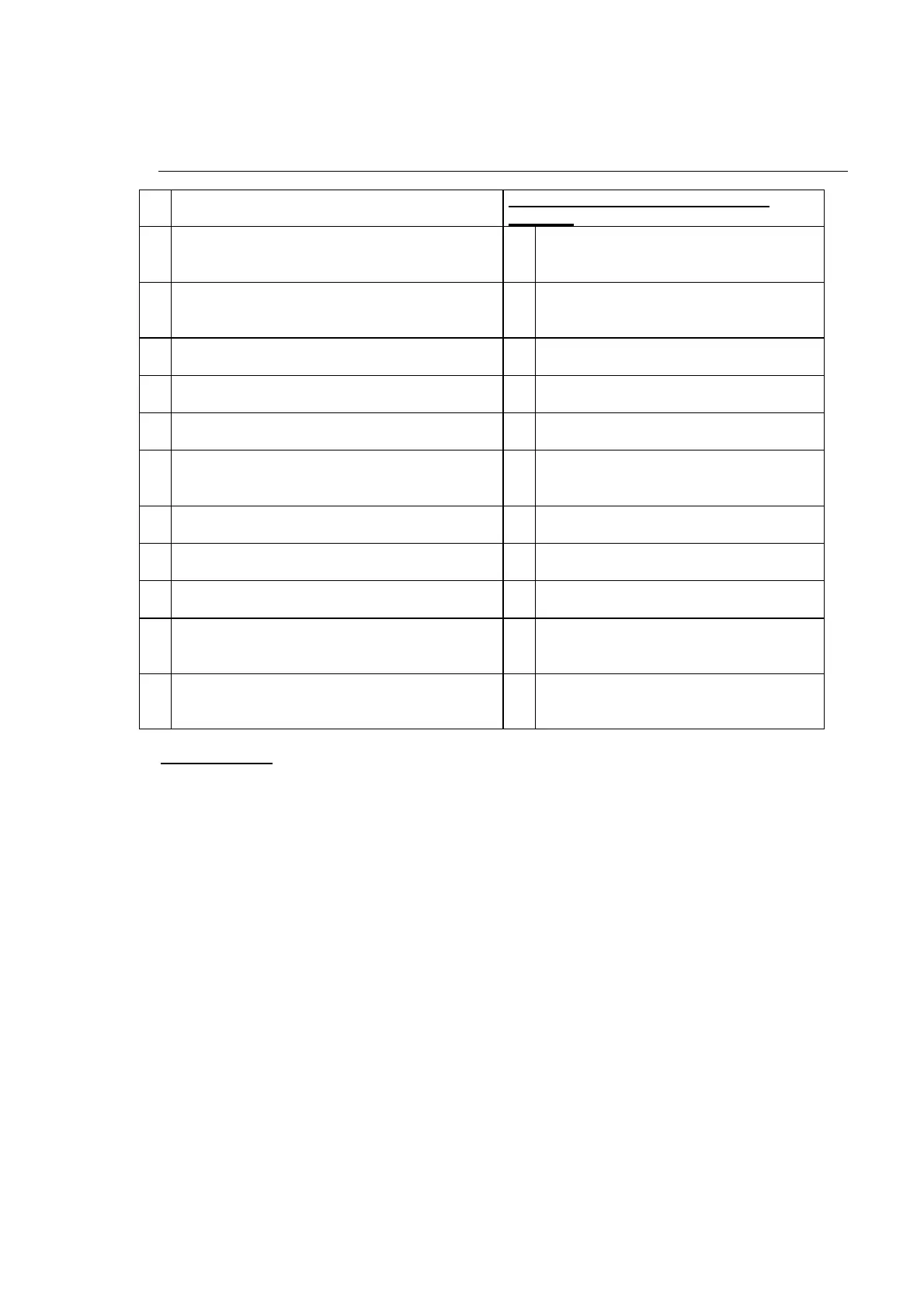

10. Operating and Monitoring Systems 10.

33 Thermal sensor, distillation:

Turns off the distillation heater

Additional operating and monitoring

systems:

34 Thermal sensor, distillation condenser:

Monitors the solvent temperature.

- Overfill sensor, disposal vessel:

Prevents an overfilling of the disposal

vessel.

35 Thermal sensor, Slimsorba after carbon:

Monitors several temperatures during

maintenance.

36 Sight-glasses, tanks 1+2+3:

You can read off the liquid level on the scale.

37,

38

Limit switch on the loading door:

Monitors loading door closing and locking.

39 Filter pressure gauge, Economy filter 1:

Visual inspection of the filter pressure.

40 Sight-glass, filter circuit:

For observing the flow and clearing of the

detergent solution.

41 0-bar (0 psi) switch:

Releases the loading door for opening.

42 0.1-bar (1.4 psi) switch:

Opens the aeration valve.

43 Thermal sensor, cage housing inlet:

Monitors the air inlet temperature

44 Main switch:

Rotary switch for separating the machine from

the electrical power system

45 Loading door window:

Observe the sign for the filling quantity. Visual

inspection of cage movement

to points 5 and 6

The cooling water controllers should be subjected to a regular function test.

When the machine is not in operation cooling water feed must be cut off by means of a stop valve to

be fitted on site.

Loading...

Loading...