19

P21/P26/P30

6. Operation 6.

6.1 First Startup 6.1

The BÖWE Customer Service department is responsible for carrying out the first startup.

Attention:

Before opening the switch panel or removing paneling,

set the main switch to " 0".

6.1.1 Preparatory Work

Set up supply systems (electrical current, cooling water, compressed air, steam and condensate

lines).

6.1.2 Filling Machine With Solvent

Use only stabilized, high-purity TETRACHLORETHENE (perc), in accordance with DIN 53978.

The amount of solvent needed is:

Machine P21 tank I: approximately: 110 l (178 kg) or 29 US gal (400 lb)

Machine P26 tank I: approximately: 135 l (219 kg) or 36 US gal (480 lb)

Machine P30 tank I: approximately: 155 l (251 kg) or 41 US gal (555 kg)

Total filling amount P21: approximately: 445 l (721 kg) or 115 US gal (1590 lb)*

Total filling amount P26: approximately: 510 l (826 kg) or 135 US gal (1820 lb)*

Total filling amount P30: approximately: 565 l (915 kg) or 150 US gal (2020 lb)*

* Machine with 1 economy filter.

For machines with 2 economy filters: + 50 l (13.2 US gal

For machines with 2 economy filters and 1 cartridge filters: + 75 l (19.8 US gal)

For machines with 2 economy filters and 2 cartridge filters: + 90 l (23.8 US gal)

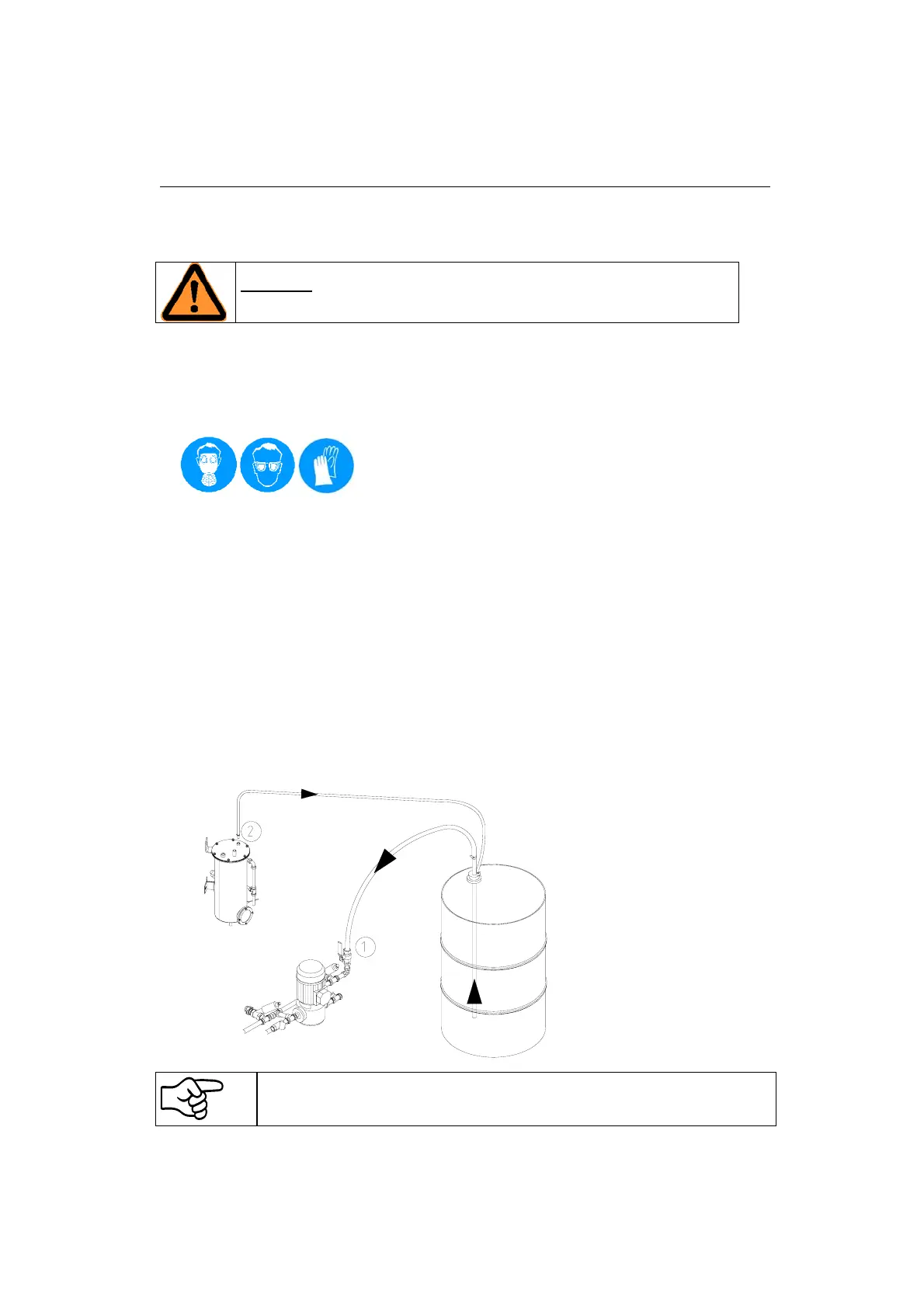

When filling the machine using the gas pendulum process, refer to diagram.

If there is no suction from the pump, pour about 5 liters (1.3 US gal) of

solvent into the button trap. Check that the direction of rotation is

correct.

Loading...

Loading...