Page 3

Use the following adjustment procedures should the lift not function as described in the certification check-

list.These procedures must be followed in order for the lift to be FMVSS 403/404 compliant.

• Vehicle movement is prevented unless the platform is fully stowed.

1. Verify lift stowed signal - pin 7 on the pump module has a +12 volt signal OR pin 9 has a ground

signal (depends on interlock used).

2. Refer to the interlock installation instructions.

• Lift operation shall be inhibited unless the vehicle is stopped and vehicle movement is prevented.

1. Verify vehicle secure signal (pin 6) has a +12 volt signal.

2. Refer to the interlock installation instructions.

• The platform will not fold/stow when occupied.

1. Position the platform at the floor level loading position.

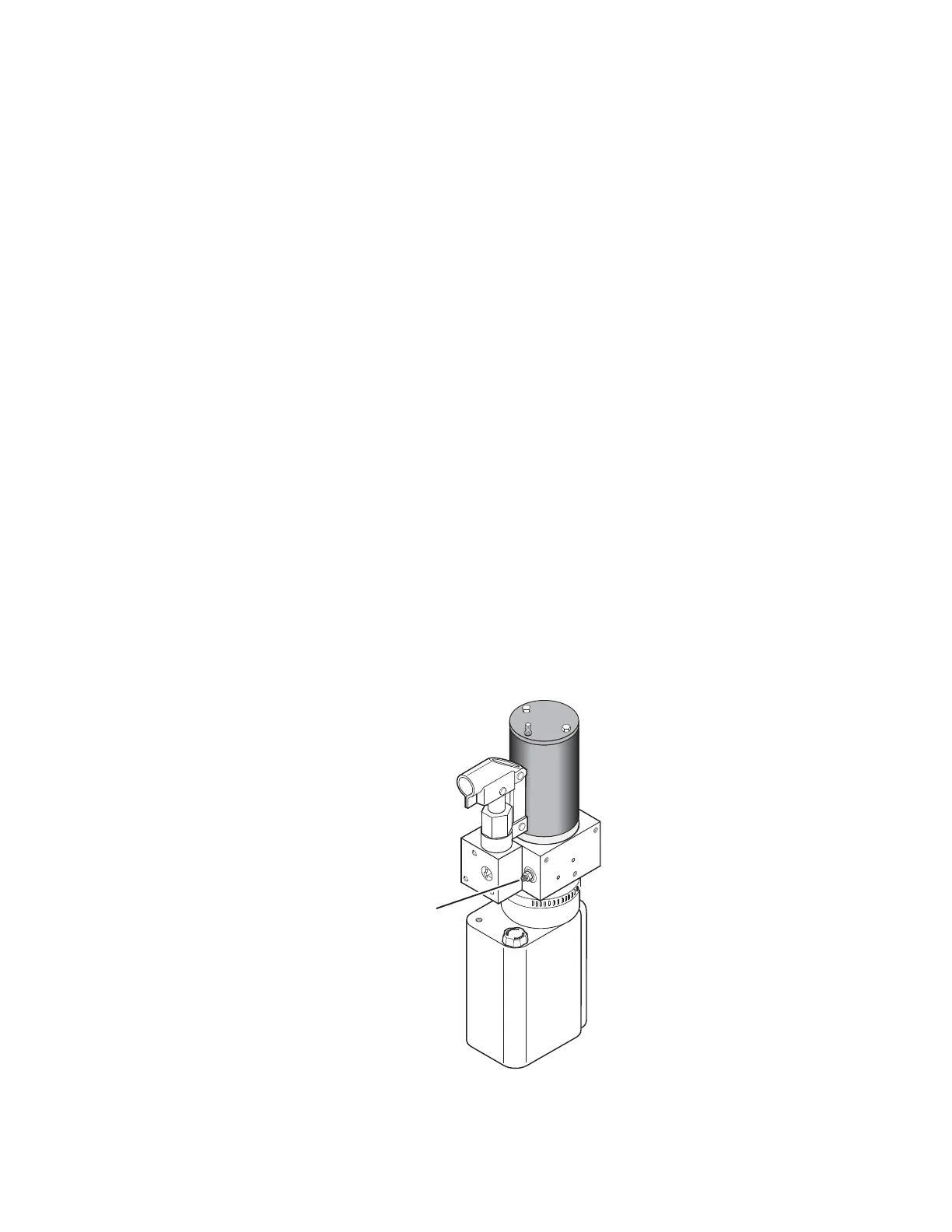

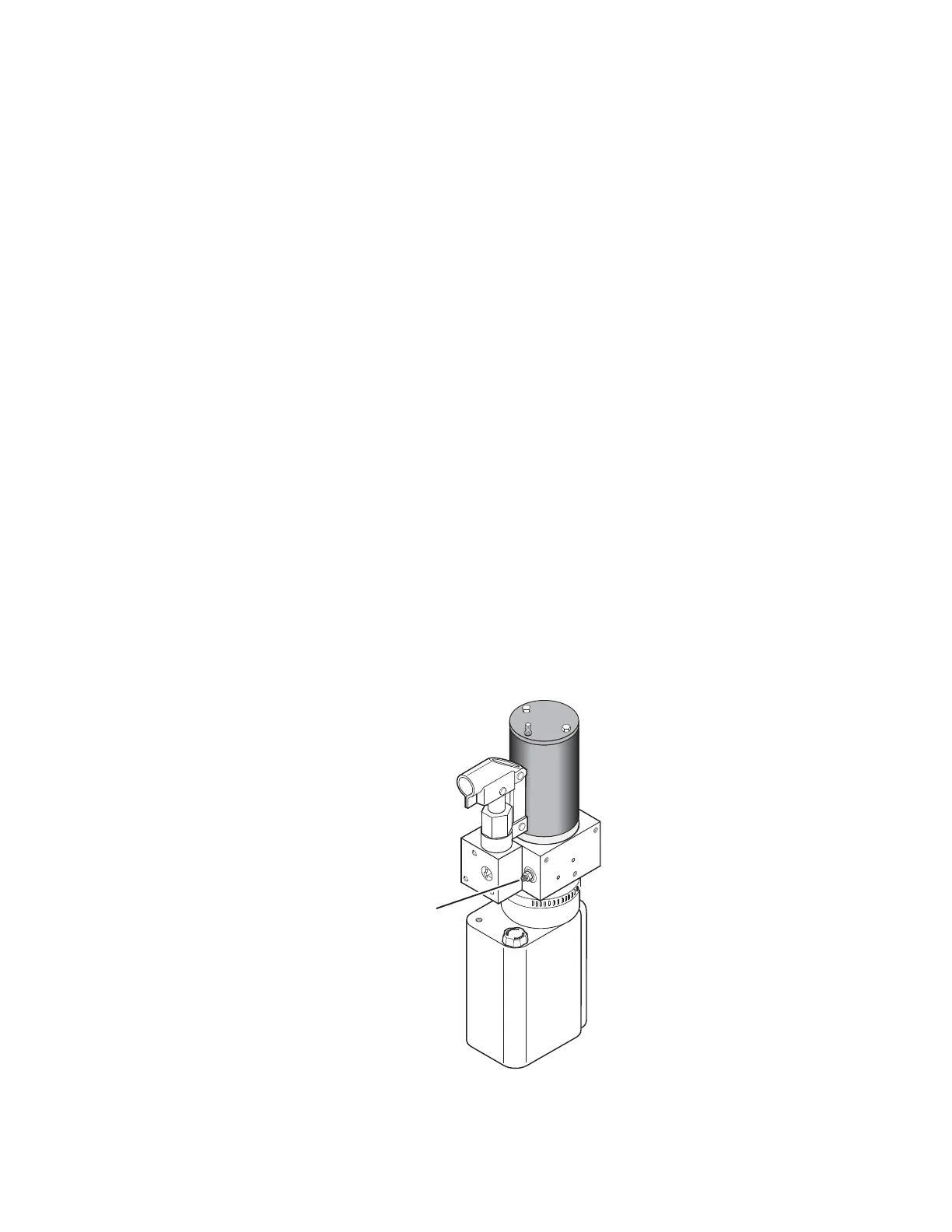

2. Loosen the locknut on the dual relief valve adjustment (do not remove locknut). See illustration be-

low.

3. Turn the adjustment screw counter clockwise until the platform does not fold when the Fold button is

pressed.

4. Turn the adjustment screw clockwise in 1/4 turn increments and press the Fold button until the plat-

form folds completely (Note: return the platform to floor level position after each attempt to fold the

platform).

5. Turn the adjustment screw an additional 1/8 turn after the platform folds successfully.

6. Tighten the locknut without moving the adjustment screw.

7. Verify the platform will not stow while occupied.

• The inner rollstop will not raise if occupied.

- Call Product Support

Platform Relief Valve

Adjustment

(Located beside Backup Pump)

Certification Checklist Diagnostic Procedures

Loading...

Loading...