150

9

11

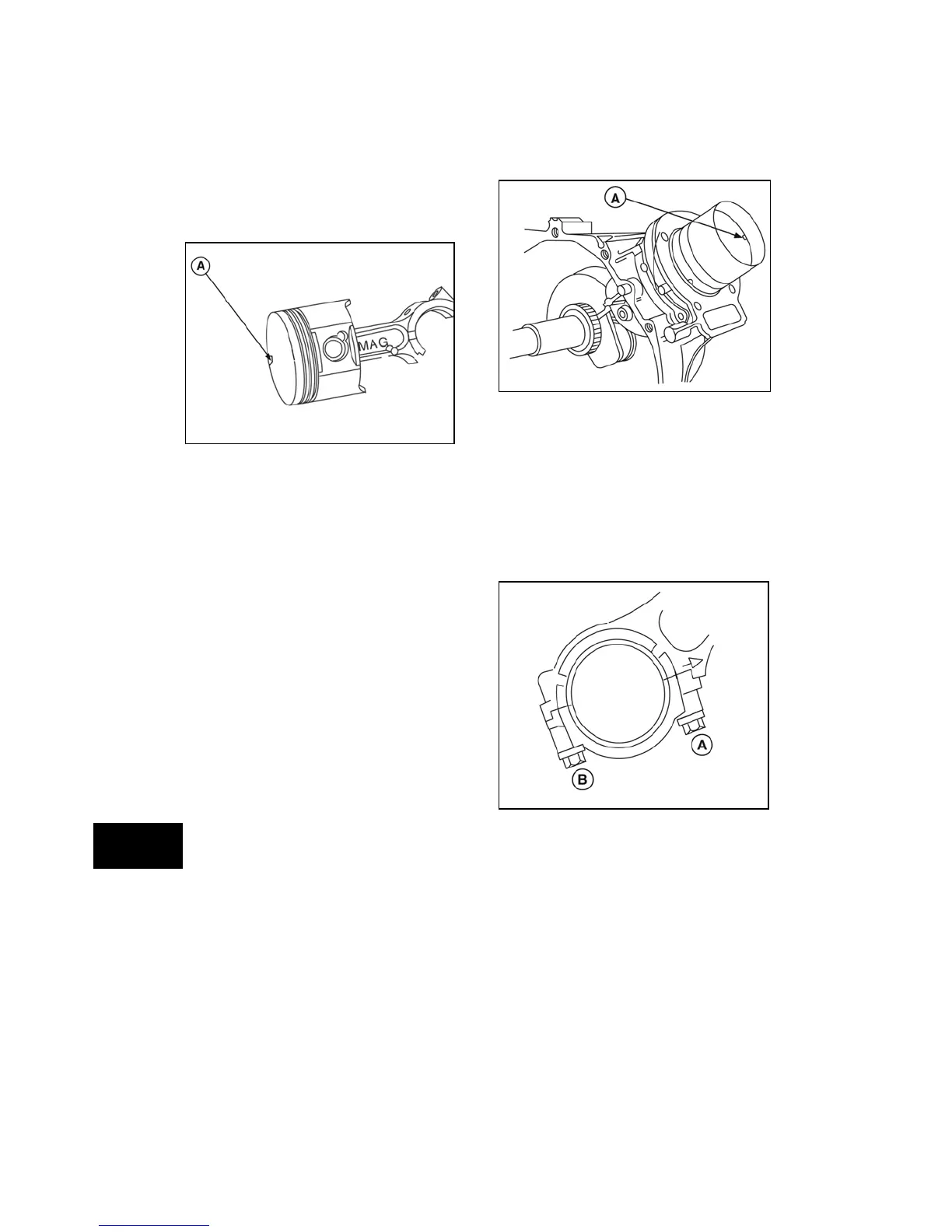

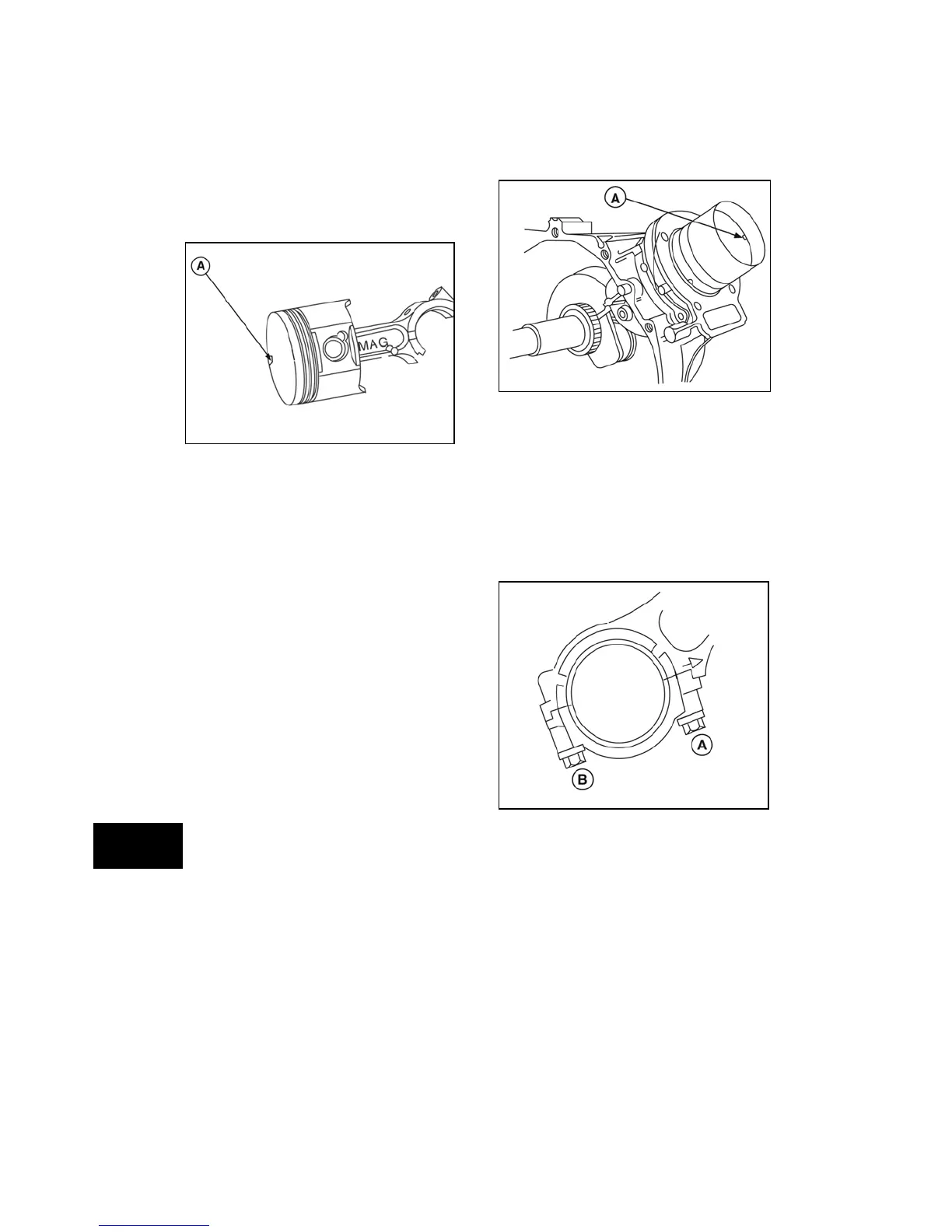

NOTE: For Vertical Model 120000 ONLY, install

piston with notch or arrow (A, Figure 8) facing

away from “MAG” on the rod. When installed in

engine, the notch will face the PTO.

Figure 8

3. Install a pin retainer into groove on open

side of piston pin bore. Ensure retainers

are firmly seated in grooves.

4. Using Piston Ring Expander #19340,

install oil ring and spring expander, then

the center ring, then the top ring. Follow

the orientation noted at time of

disassembly, or use the instructions

provided if installing a new ring set.

NOTE: If oil ring consists of two steel rails and a

spring expander, they must be installed by hand

as follows:

• Grasp one end of lower steel rail and

wind it over the top ring groove, then into

the center ring groove, and finally into the

oil ring groove.

• Install the spring expander on top of the

lower rail, then install the upper steel rail.

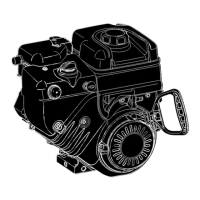

Install Piston and Connecting Rod

1. Thoroughly clean and oil cylinder bore and

crankpin journal.

2. Rotate crankshaft until crankpin journal is

at bottom of stroke.

3. Using Ring Compressor Tool #19070 or

#19230, install piston with notch or arrow

(A, Figure 9) toward flywheel side of

engine, taking care not to damage

crankpin journal or connecting rod

bearing.

Figure 9

4. Fit connecting rod bearing on crankpin

journal, then install rod cap with match

marks aligned.

5. Cap should snap into position when

assembled correctly. Install rod screws

(and dipper, if equipped).

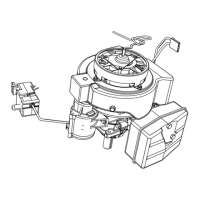

6. Tighten screw closest to piston (A, Figure

10) first, then screw farthest from piston

(B) second. Torque screws to values listed

in Section 12 - Engine Specifications.

Figure 10

NOTE: Failure to use a torque wrench can result

in loose rods causing breakage, or over-

tightened rods causing scoring.

7. Rotate crankshaft two revolutions to

ensure crankpin and rod do not bind.

8. Move connecting rod sideways to ensure

rod has clearance on crankpin side.

Loading...

Loading...