18

Sometimes, inaccurate balance or incorrect position is caused by the breakage of the press sensor. The

changing method of the sensor is as following:

(1)Remove the upper cover and the right side panel of the balancer.

(2)Detach the nut1 and 2, elastic washer, plain washer and large flat washer.

(3)Loose the back nut3.4.5 to detach every parts.

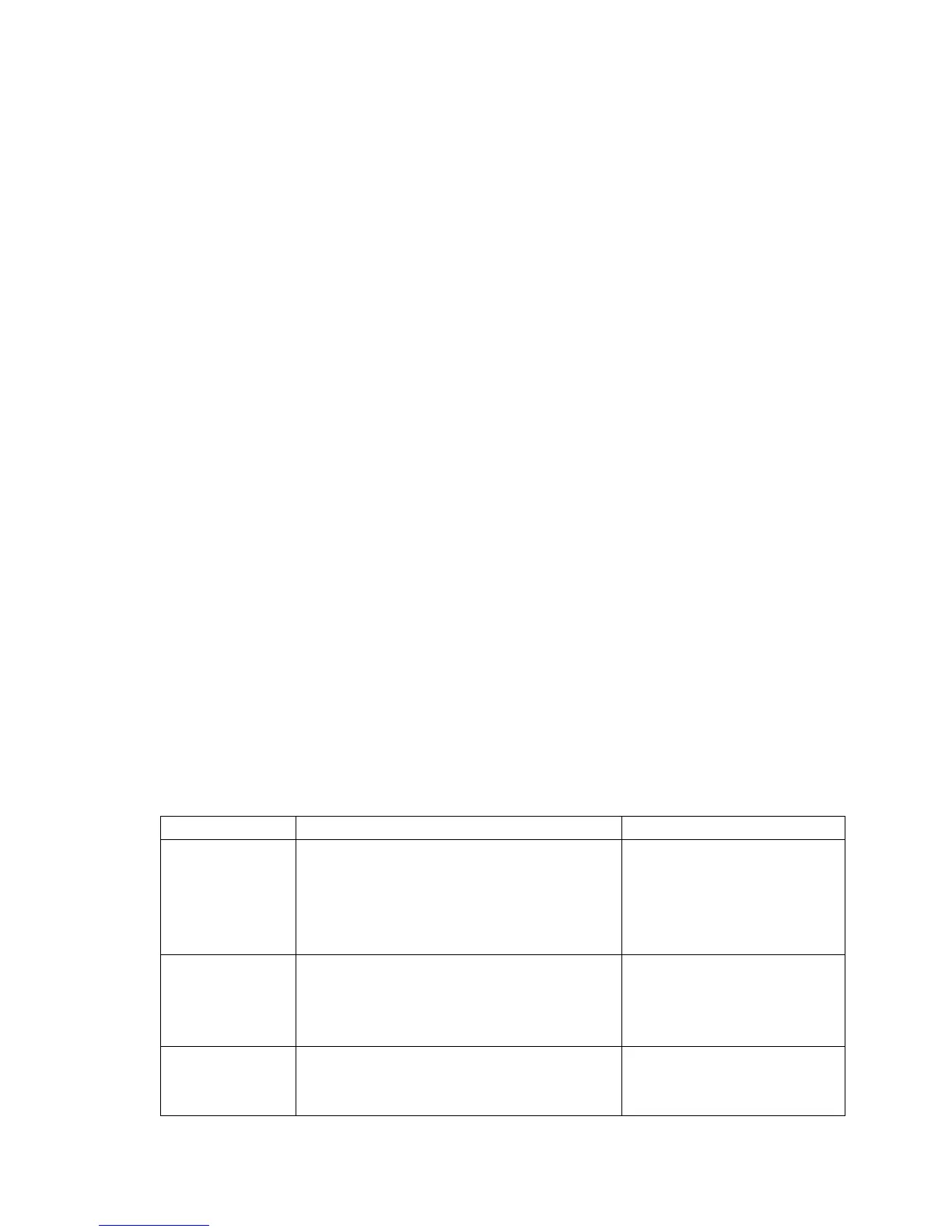

(4)Change the new sensors and tight the dual-head screw and then tight nut 5. The installation of the

negative and positive pole of the piezoelectric ceramics disk of the sensor must follow the picture.

(5)Use the spanner to tight the nut4 and then nut 3. At this moment, you should pay attention

to the horizontal and vertical sensor screws should be vertical. And the end of the screws should

be just fallen into the 2 holes.

(6)Mount the nut1 and 2, elastic washer, plain washer and large flat washer and completely tigh them.

Usually, lock nut 1 and then nut 2. We require to flat the elastic washer and then return the nut

1/4—1/2turn. Use this way to get the normal pre-pressure of the press sensor(use torque wrench to lock

and the torque is 40NM)

(7)There are glass glue coat on the surface of the press sensor and the normal installation result

of the piezoelectric ceramics disk of the sensor is the IR should be larger than 50MΩ.

(8)Discharge the output line of the shortcuts press sensor,insert into the computer board after discharge

to avoid the breakage of the computer board.

(9)Insert the vertical(┴)& horizontal(∥)sensor plugs according to the original position.

(10)Calibrate the balancer again and install the upper cover and the side panel after check result is

normal.

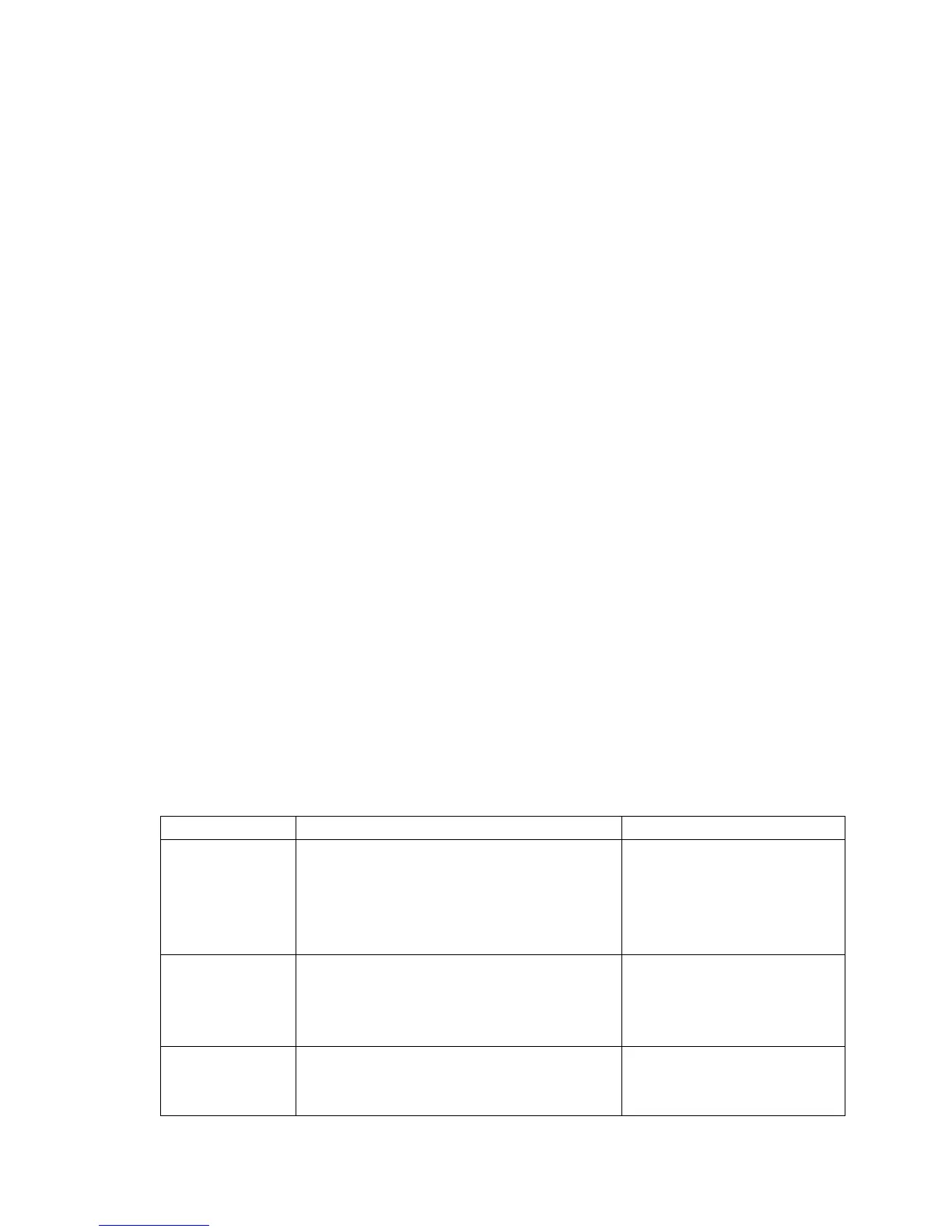

7.4 GENERAL TROUBLESHOOTING & SOLUTION:

Loading...

Loading...