-noise ≤69dB

-rim diameter 10″~30″

-maximum wheel weight75kg

-rim width 1.5~20″

-net weight 155 kg

-max wheel diameter 47inch

-working environment:temperature 0℃-50℃,RH:

30% —80% (no condense);

3.3 WORK PRINCIPLE

The micro CPU will provide the normal information if it

checks each unit in the normal situation. And the

operators can execute the balance operation. When

balancing, MCPU can control the rotation of the

balancer tester main shaft through the drive interface.

The unbalance signal sensed by balance sensor is sent

to the micro-processor port through A/D converter. CPU

will integrated analyze the unbalance signal and angle

signal to calculate the unbalance value and display the

value through the LED unit. We can realize the

man-machine talk through keyboard and LED.

FIG 3 CB958 WHEEL BALANCER WORK PRINCIPLE

4. INSTALLATION &

TRANSPORTATION

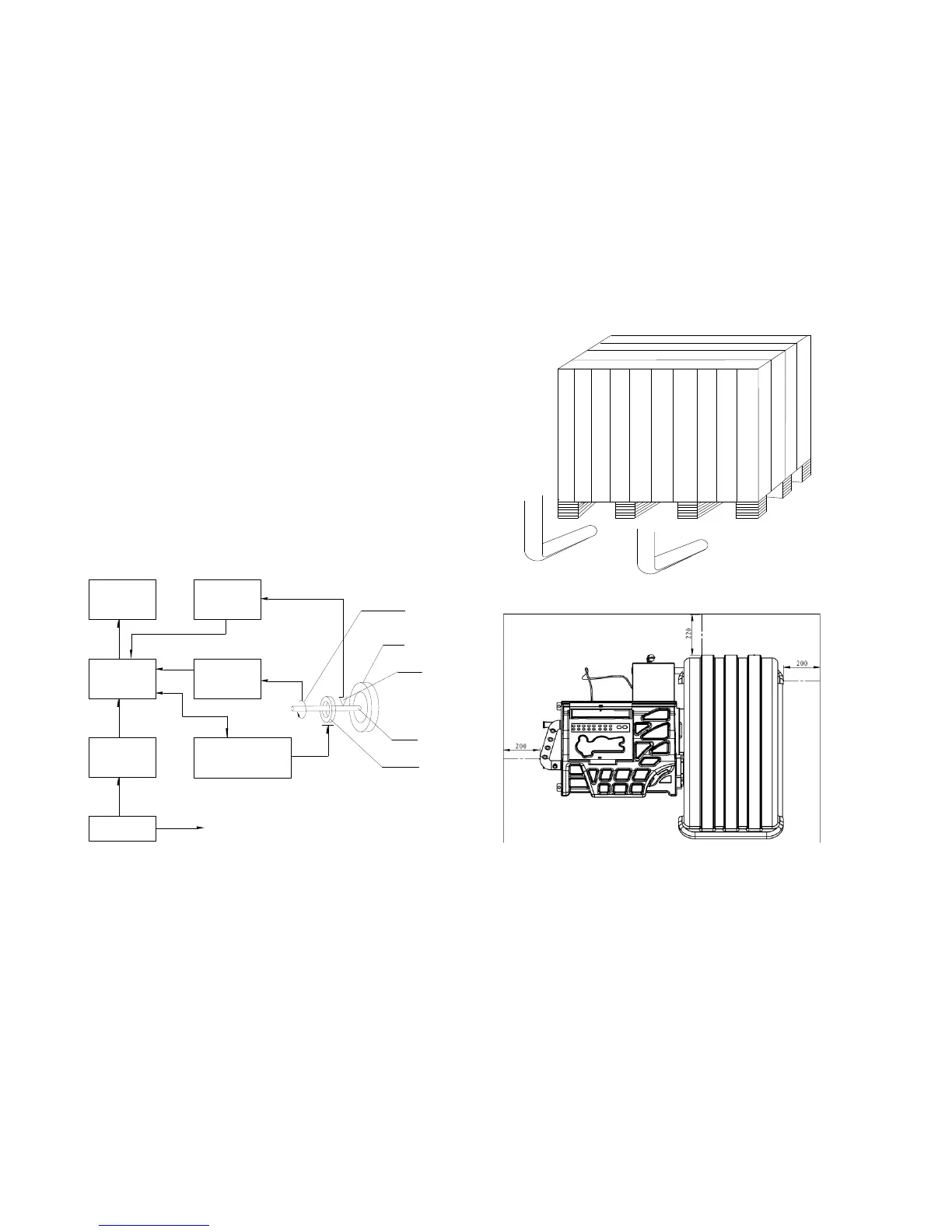

4.1 TRANSPORTATION

-Place, carry and store the machine according to the

indication of the label on the package carton.

- Store environment: RH20%-95%

temperature-10℃-+60℃

-When transport and use the machine, do not pull the

rotation shaft, or it will cause the permanent damage.

4.1.1 After being sure that the package of your machine

is perfect, you can carry the wheel balancer to the

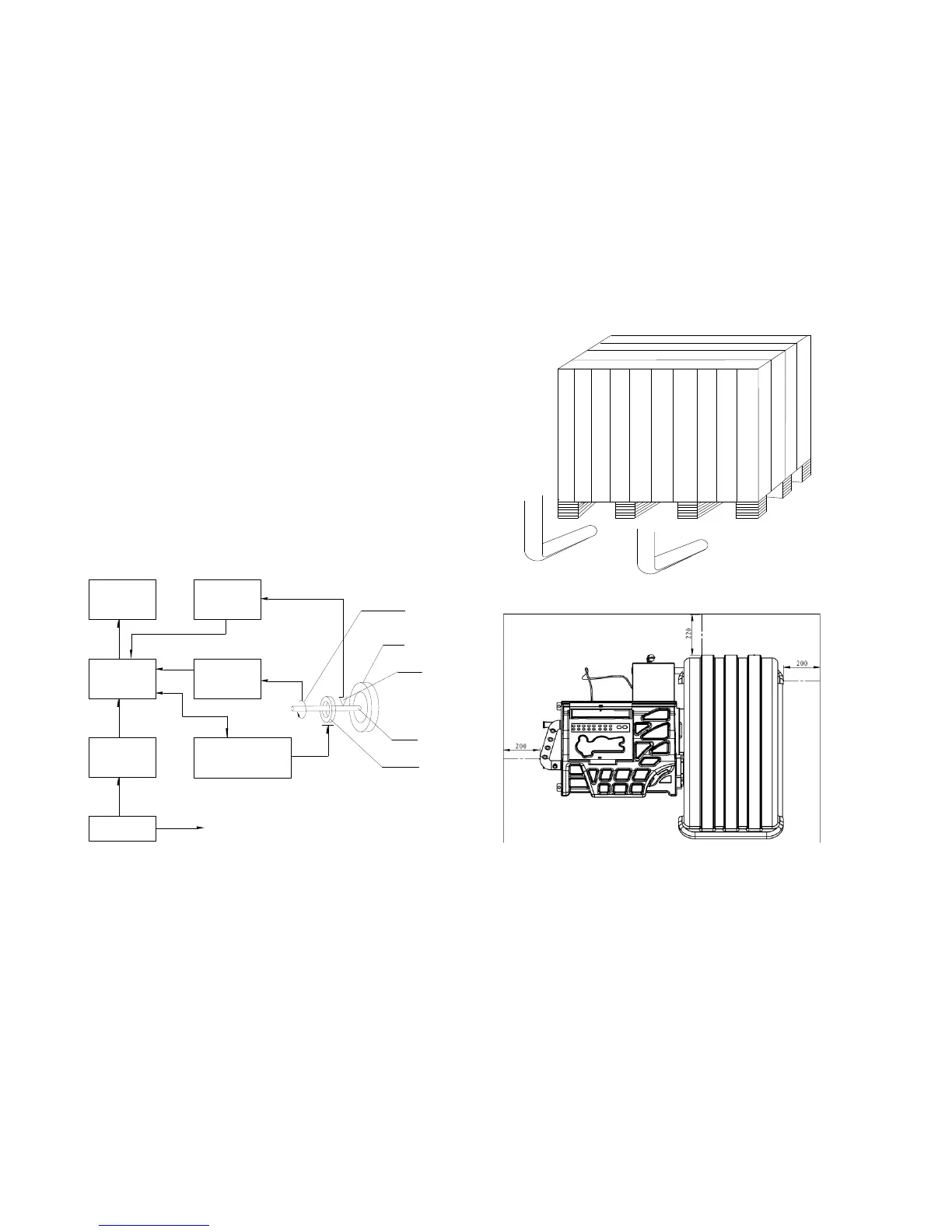

installation site.(Fig4). The choice of the installation

should comply with the following requirements. The

ambient temperature is 0℃-50℃ and the RH ≤85%. And

the installation site as shown in Fig5

4.1.2 Remove all packaging and check contents with

below list of items. If any parts missing or damaged,

please contact your distributor.

Packing material such as plastic, Polystyrene, nail,

screw, timber and carton must be placed

into a scrap box and be handled in accordance to the

local regulation and law.

4.2 INSTALLATION

Loading...

Loading...