2. Change the power board

3. Change the computer board

Balance is not

accurate & difficult

to reach ―00‖

1. sensor lead connect or contact no good

2. memory value lost

1.Connect again

2. Correct the memory value

according to the manual.

Each spin, the

change of the value

will not exceed 5g.

1. There are foreign body on the rim or the

assemble surface in the rim center deformation

2. sensor damp or quick nut not tightly clamped

3. The external power voltage or the air pressure

not enough. The flange dick not locked.

1. Change the wheel

2. Oven, recalibrate the sensor.

3. Fix the anchor bolt.

Each spin, the

range of the change

of value will be

20-90g.

1. There are foreign bodies on the wheel or the

unbalance of the wheel value too big.

2. sensor damage

3. external power source voltage too low

1. Change the wheel

2. Check the sensor and wiring.

3. Check power source and

assemble stabilizer.

Balance is not

accurate & difficult

to reach ―00‖

1. Sensor damp or damage

2. Program chore

1. Calibrate again,oven and then

self-calibration or change.

2. Self-calibration again

When second

mount & demount,

the error will exceed

10g.

1. Wheel internal hole irregular

2. Flange disk assemble not properly

1. Change the wheel

2. Check the assemble surface

and try again.

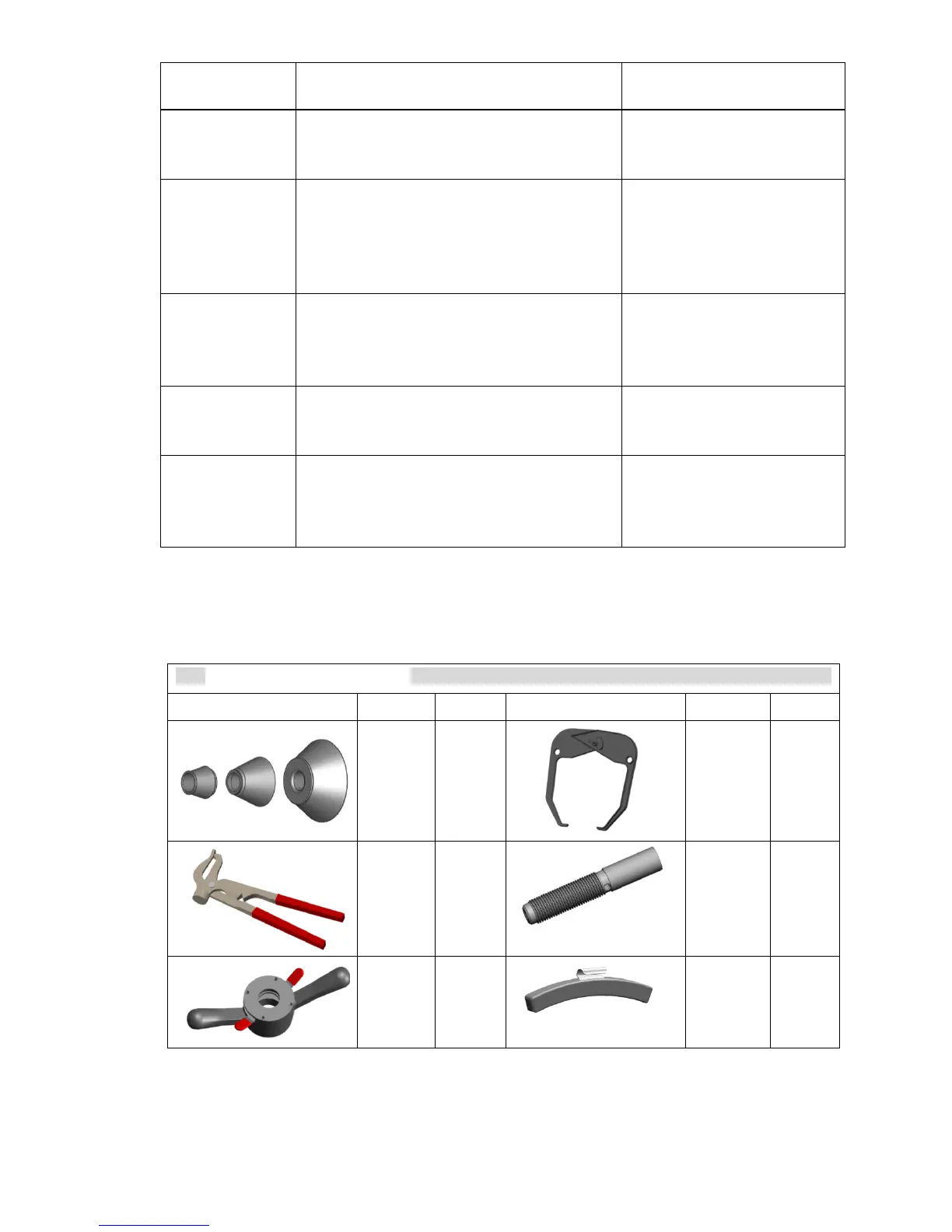

7.5 ACCESSORIES OF THE WHEEL BALANCER

Loading...

Loading...