Model 671 User’s Manual APPENDIX F – LOGGED STATUS MESSAGES

Bristol Instruments, Inc. 58

APPENDIX F – LOGGED STATUS MESSAGES

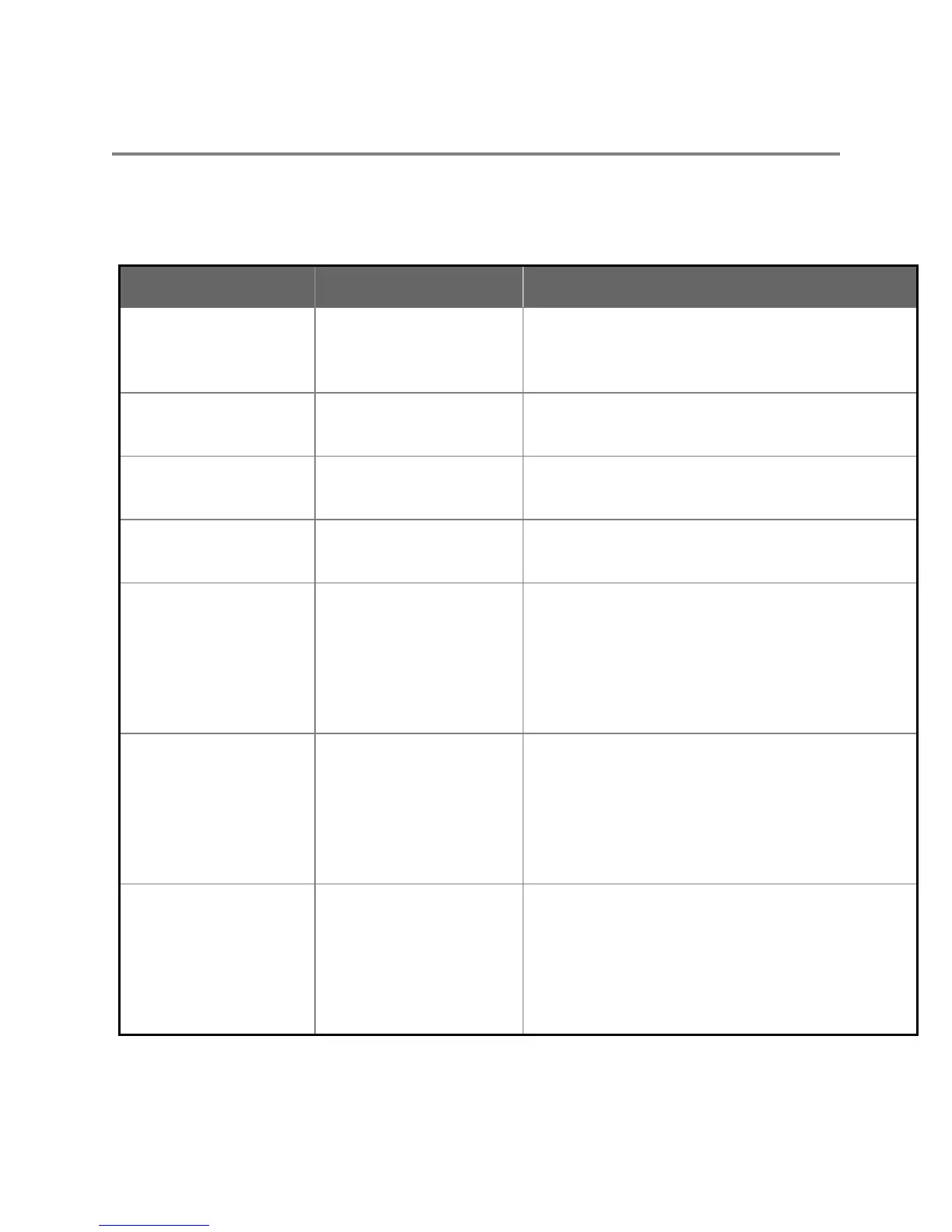

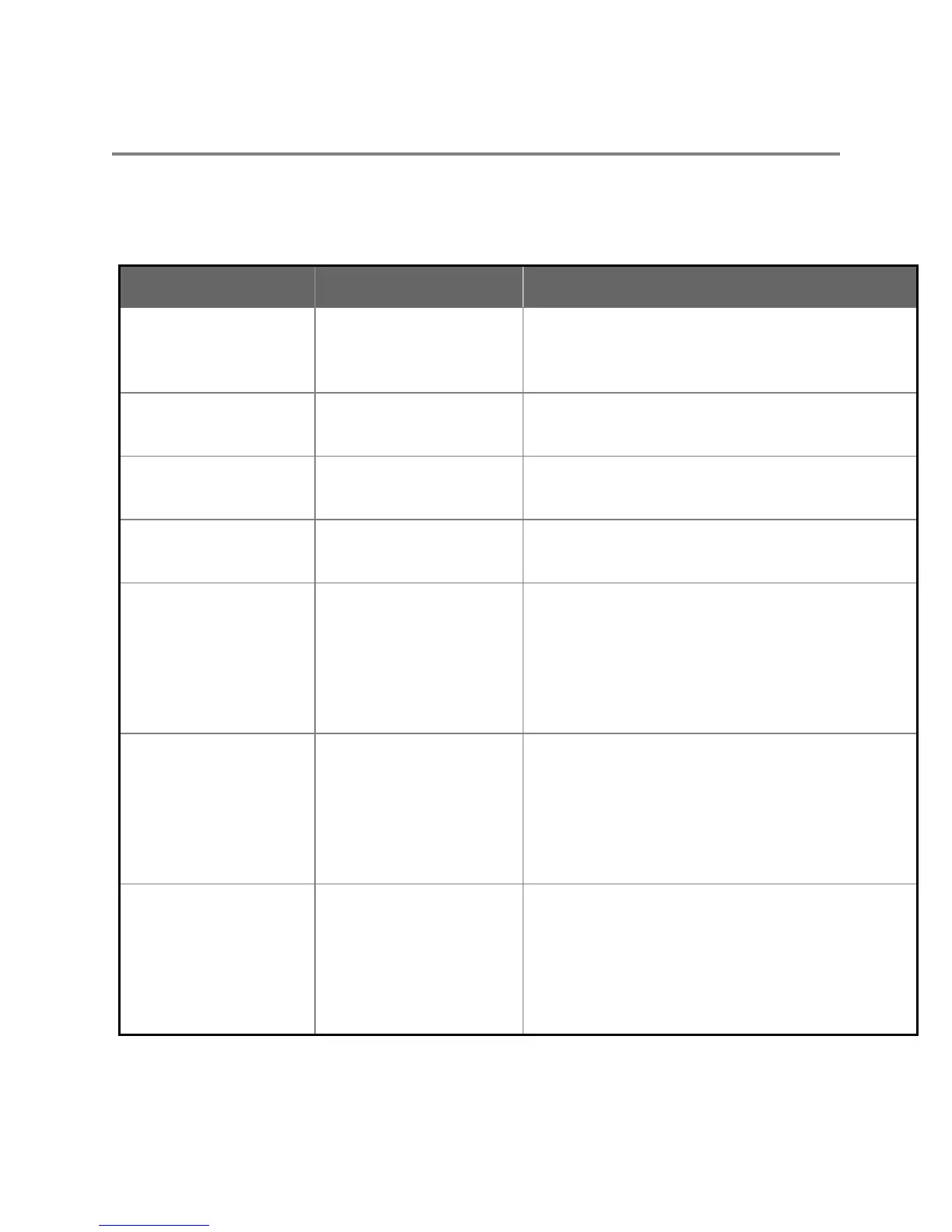

The 671 Laser Wavelength Meter reports the instrument status at each measurement as

a hexadecimal number in the log file. The hexadecimal number corresponds to a set of

status messages that are explained in the table below. For additional information about

the status messages, please contact Bristol Instruments.

This indicates the direction of the scan that each

measurement was collected on. This bit is set for left

scans, and not set for right scans.

The instrument has detected a power measurement

that is outside of the specified range of the instrument.

The instrument has detected a power measurement

that is outside of the specified range of the instrument.

Reference Laser Not

Stable

This indicates that the internal HeNe reference laser of

the model A has not stabilized yet.

This indicates that the instrument temperature is

outside of the allowed range of 0C to 50C for the

temperature sensor, or that there is a problem with the

sensor. Measurement will continue using the

temperature at the end of the allowed range closest to

the temperature sensor’s reading.

This indicates that the instrument temperature is

outside of the allowed range of 0C to 50C for the

temperature sensor, or that there is a problem with the

sensor. Measurement will continue using the

temperature at the end of the allowed range closest to

the temperature sensor’s reading.

This indicates that the ambient pressure is outside of

the allowed range of 500 to 900 mm Hg, or that there

is a problem with the pressure sensor. Measurement

will continue using the pressure at the end of the

allowed range closest to the pressure sensor’s

reading.

Loading...

Loading...