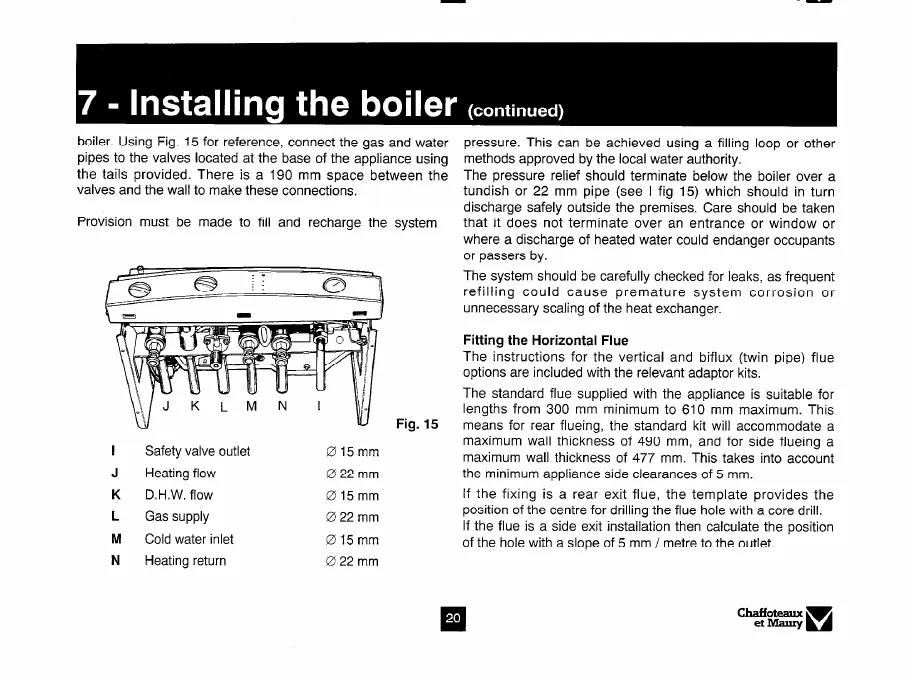

boiler. Using Fig. 15 for reference, connect the gas and water

pipes to the valves located at the base of the appliance using

the tails provided. There is a 190 mm space between the

valves and the wall to make these connections.

Provision must be made to fill and recharge the system

Fig. 15

Safety valve outlet

Heating flow

015mm

022mm

pressure. This can be achieved using a filling loop or other

methods approved by the local water authority.

The pressure relief should terminate below the boiler over a

tundish or 22 mm pipe (see I fig 15) which should in turn

discharge safely outside the premises. Care should be taken

that it does not terminate over an entrance or window or

where a discharge of heated water could endanger occupants

or passers by.

The system should be carefully checked for leaks, as frequent

refilling could cause premature system corrosion or

unnecessary scaling of the heat exchanger.

Fitting the Horizontal Flue

The instructions for the vertical and biflux (twin pipe) flue

options are included with the relevant adaptor kits.

The standard flue supplied with the appliance is suitable for

lengths from 300 mm minimum to 610 mm maximum. This

means for rear flueing, the standard kit will accommodate a

maximum wall thickness of 490 mm, and for side flueing a

maximum wall thickness of 477 mm. This takes into account

the minimum appliance side clearances of 5 mm.

K D.H.W. flow 015mm

If the fixing is a rear exit flue, the template provides the

L

Gas supply 022mm

position of the centre for drilling the flue hole with a core drill.

M

Cold water inlet 015mm

If the flue is a side exit installation then calculate the position

of the hole with a slope of 5 mm / metre to the outlet.

N Heating return 022mm

Loading...

Loading...