IOM BiRotor Plus R27Page 27/58

9.7 - Complete Reassembly (B27 thru B34)

1. Ensure all parts are clean and free of debris.

2. Lubricate all bearings and internal O-rings with

a light oil.

NOTE:

All O-rings should be replaced with new ones

during reassembly.

3. Press bearings into the end plates. Use a hand

press and ensure that the bearing is pressed

on the outer race to avoid damage. The bearing

races should be flush with the bottom of the

end plate once the bearings have been pressed

in correctly. The outer race of an old bearing

can be used to assist in proper seating.

4. Attach one end plate to the measuring unit

body at the end opposite the O-ring grove

in the measuring unit body. Align the dowel

pins and gently tap into place with a plastic or

rubber mallet. Once fully seated secure the end

plate with screws.

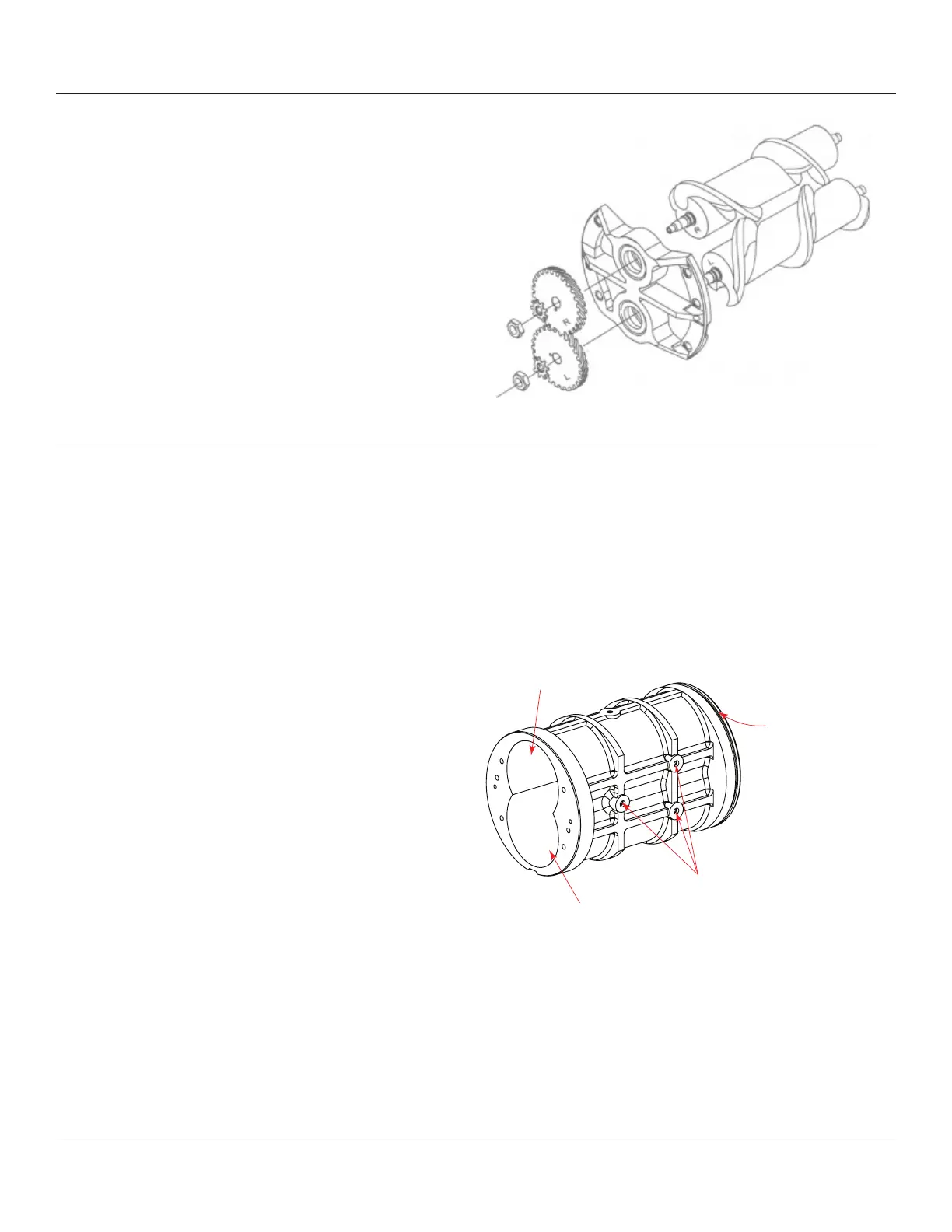

5. Each rotor and timing gear is marked with an

‘R’ or an ‘L’. During assembly the inscriptions

need to be matched. To orientate the rotors

during assembly the measuring element

body has three holes machined into it for

manufacturing purposes. These holes should be

positioned so that they face upwards. With these

holes facing upwards turn the housing so that

the end with O-ring groove is closest to you. With

the housing in this position the rotor marked with

an ‘R’ goes in the right hand cavity and the rotor

marked with an ‘L’ goes in the left hand cavity.

12. The bearings can be removed from the end

plates by pressing on the inner race of the

bearings from the outside of the plate. If the

bearings are removed from the endplates, then

they must be replaced. Timing gears must be

replaced whenever bearings are replaced.

13. Remove the other end plate from the

measuring element housing and remove the

bearings.

14. Remove the sensor housing from the inlet

housing by removing found Allen screws

located in the counter sunk holes under the

circuit board.

Figure 9-4 Rotor and Gear Orientation

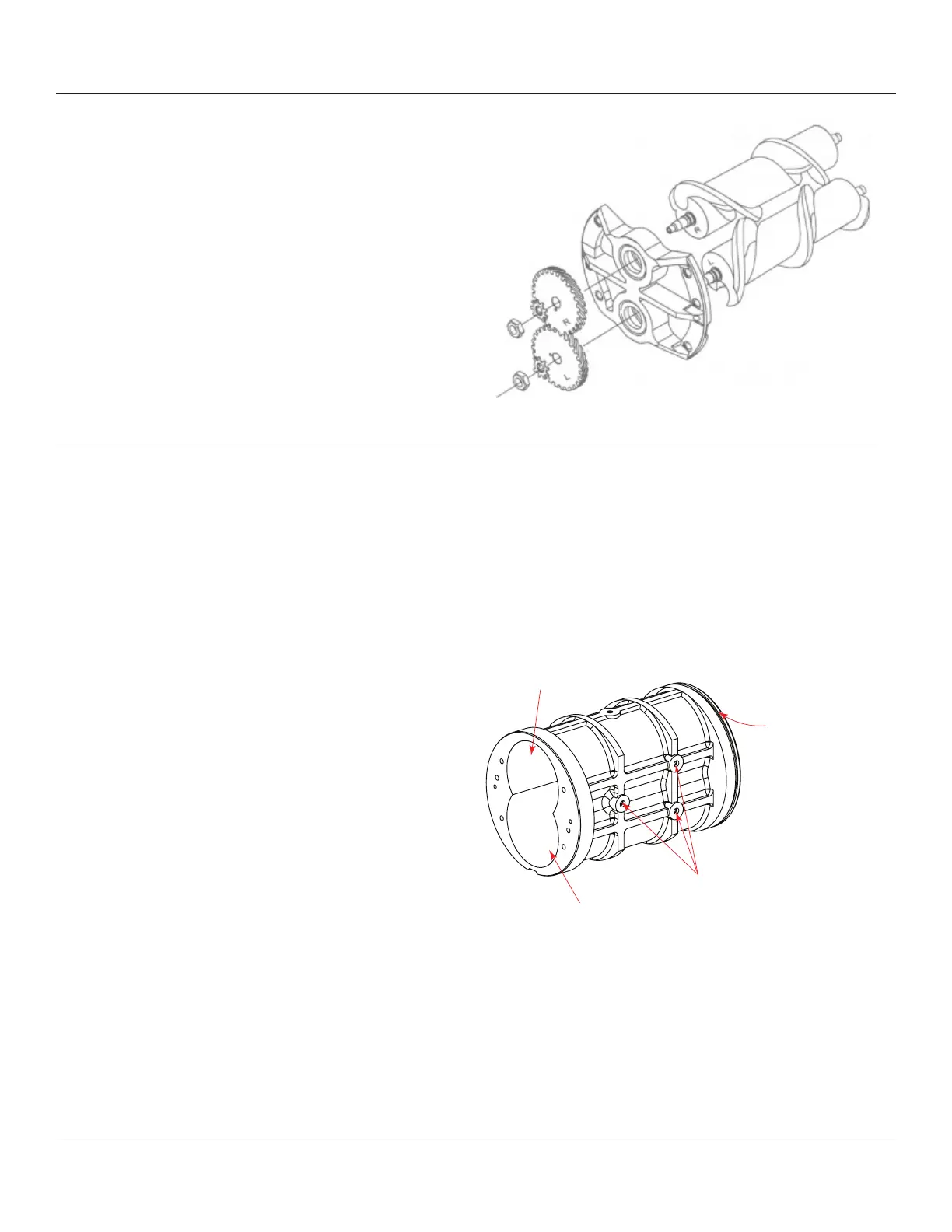

Figure 9-5 Measuring element body

Machined Holes

Right hand rotor in this bore

Left hand rotor in this bore

O-ring groove

Loading...

Loading...