IOM BiRotor Plus R27Page 33/58

11 Strainers

Strainers are installed in pipe lines ahead of pumps, meters, valves, etc., to protect such equipment against

intrusion of pipe scale, welding spatter and other foreign material.

The use of the proper size strainer together with a basket of suitable mesh pays dividends in reduced

maintenance on mechanisms which are in contact with flowing liquids. When it is known that comparatively

large amounts of lint or iron oxide are present in a stream, a large strainer should be used as these materials

clog up basket screens rapidly-especially if resins, gums or varnishes are also present.

Larger size foreign matter such as pebbles, welding beads, etc., should be removed at frequent intervals to

prevent their abrasive action from damaging the basket screen.

There is a Brodie Strainer of the proper size and pressure rating to accommodate the full line of Brodie Flow

Meters.

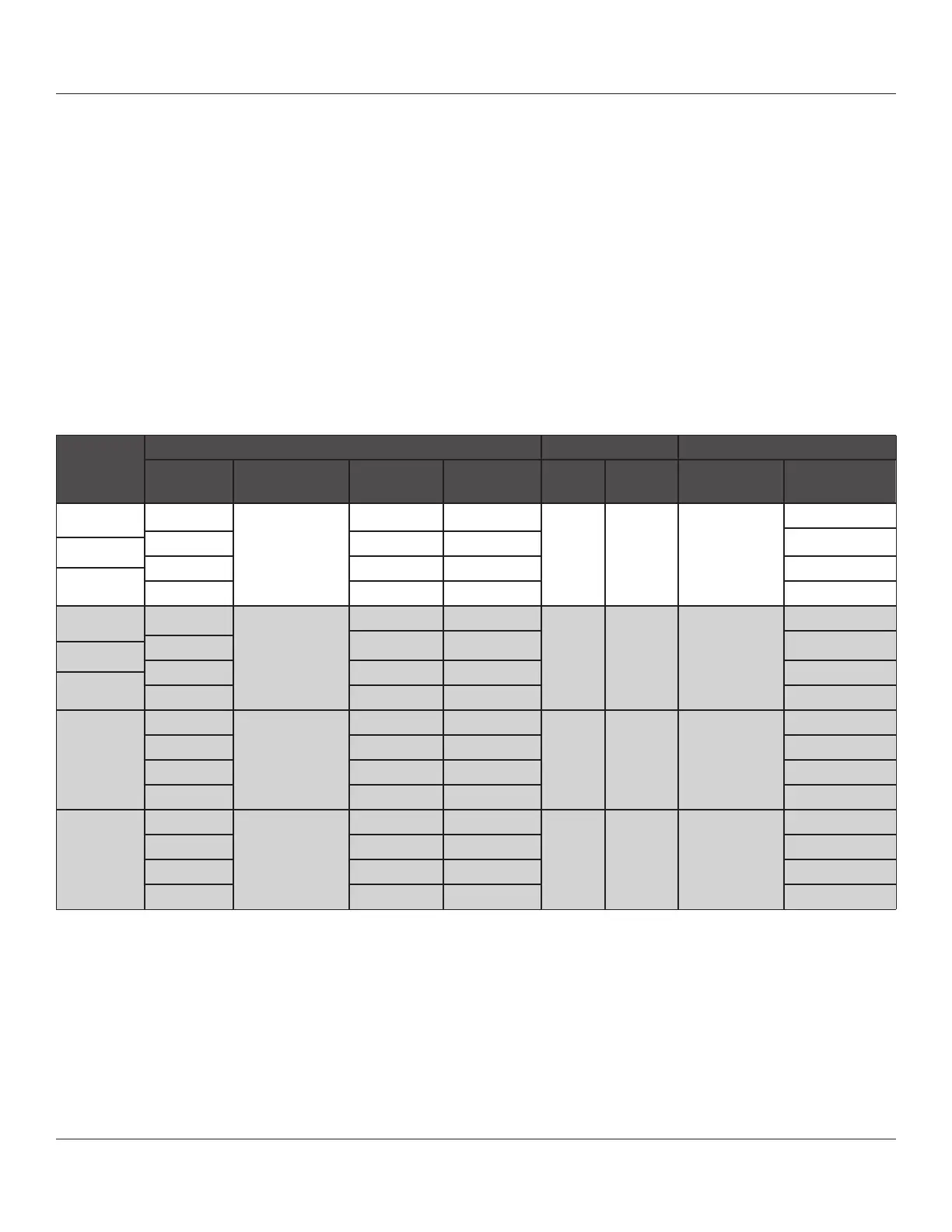

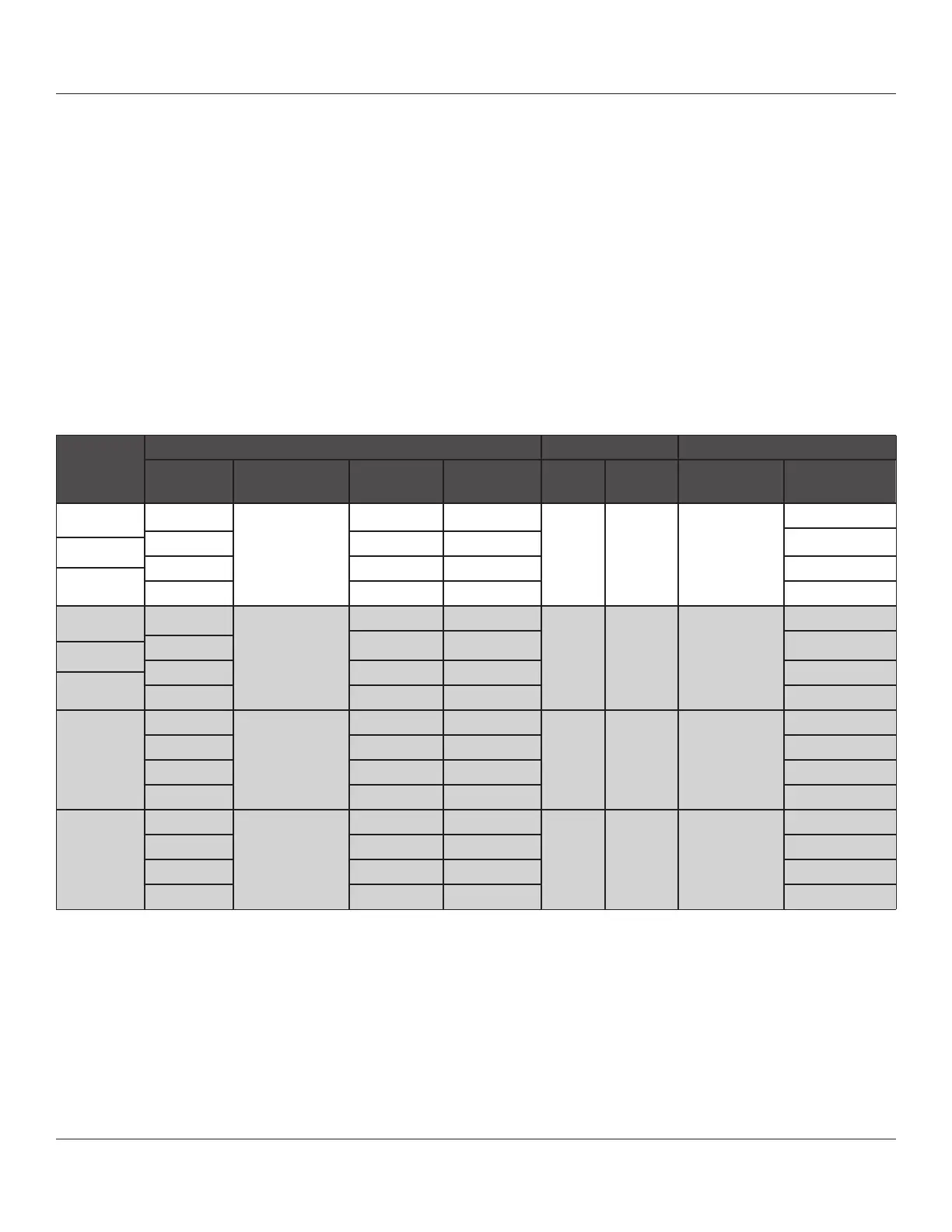

Model

Strainer

Screen Pipe Line Ratio

Mesh of

screen

Total screen

area Sq. in.

Percent

Open area

Open Area

sq. in.

Size

Area

Sq. In.

Toal Area to

pipe Area

Open Area

to Pipe Area

D-3

20

113

46.2 % 52.2

3” 7. 39 15.3 : 1

7.1 : 1

5.9 : 1

40 38.2 % 43.4

DA-3

60 30.5 % 34.5 4.7 : 1

DA-3A

80 31.4 % 35.5 4.8 : 1

D-3-4

20

113

46.2 % 52.2

4” 12.73 8.9 : 1

4.1 : 1

38.4 % 43.4 3.4 : 1

40

DA-3-4

60 30.5 % 34.5 2.7 : 1

DA-3-4-A

80 31.4 % 35.5 2.8 : 1

D-6-4

20

314

46.2 % 145.1

4” 12.73 24.7 : 1

11.4 : 1

40 38.2 % 120.6 9.5 : 1

60 30.5 % 95.8 7.5 : 1

80 31.4 % 98.6 7.7 : 1

D-6

20

314

46.2 % 145.1

6” 28.89 10.9 : 1

5.0 : 1

40 38.2 % 120.6 4.2 : 1

60 30.5 % 95.8 3.3 : 1

80 31.4 % 98.6 3.4 : 1

Loading...

Loading...